Quick-release sewage disposal method for reverse osmosis water treatment pipeline

A reverse osmosis water and quick-release technology, which is applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems affecting work progress and labor-intensive cleaning methods, and achieve Easy to operate, save working time, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

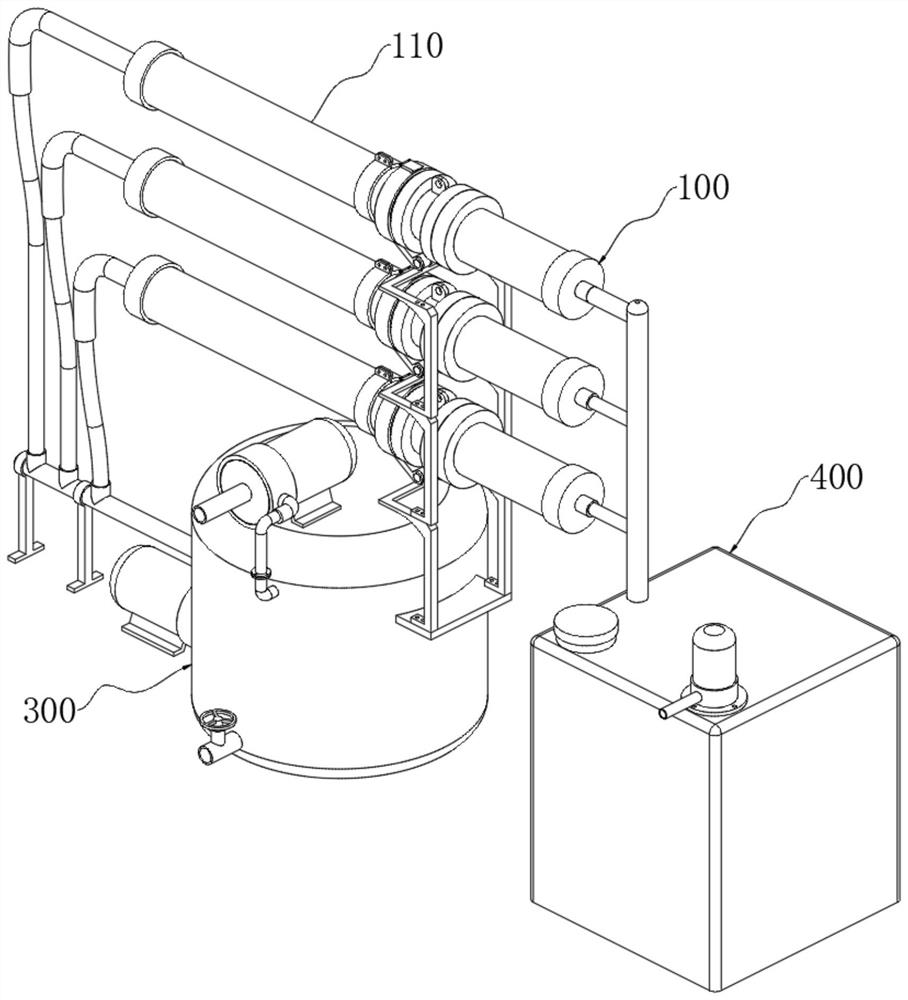

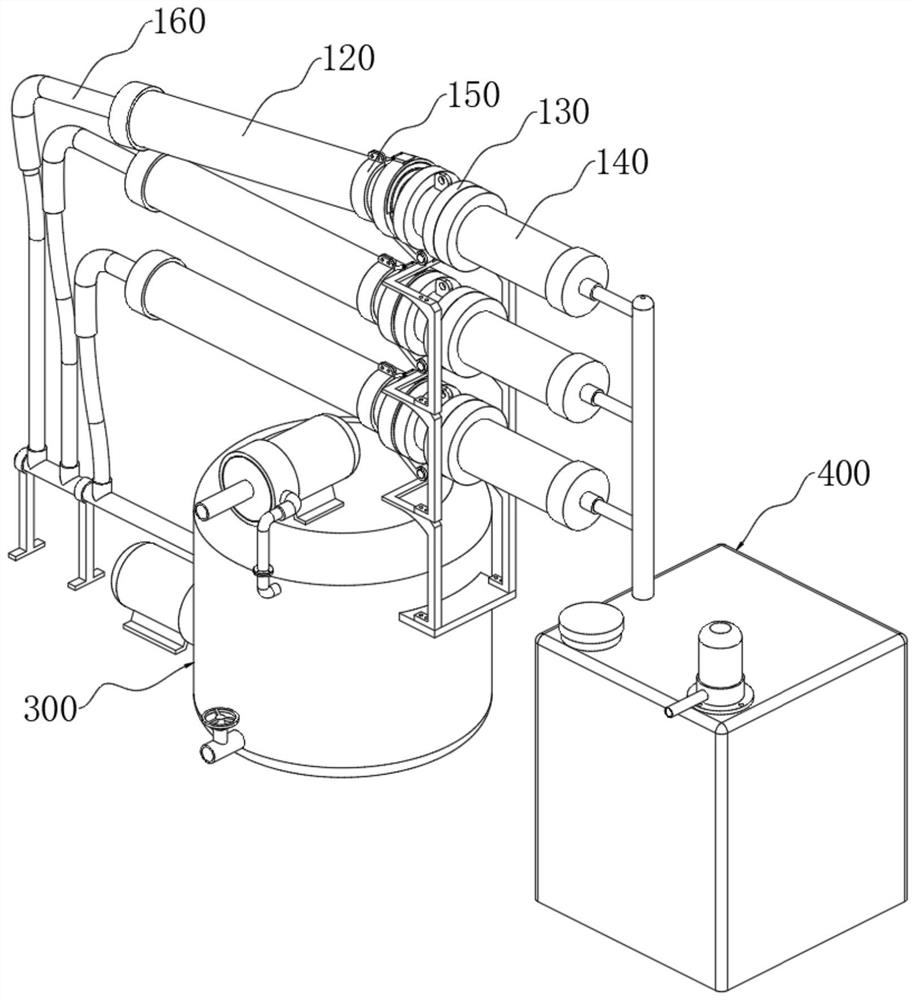

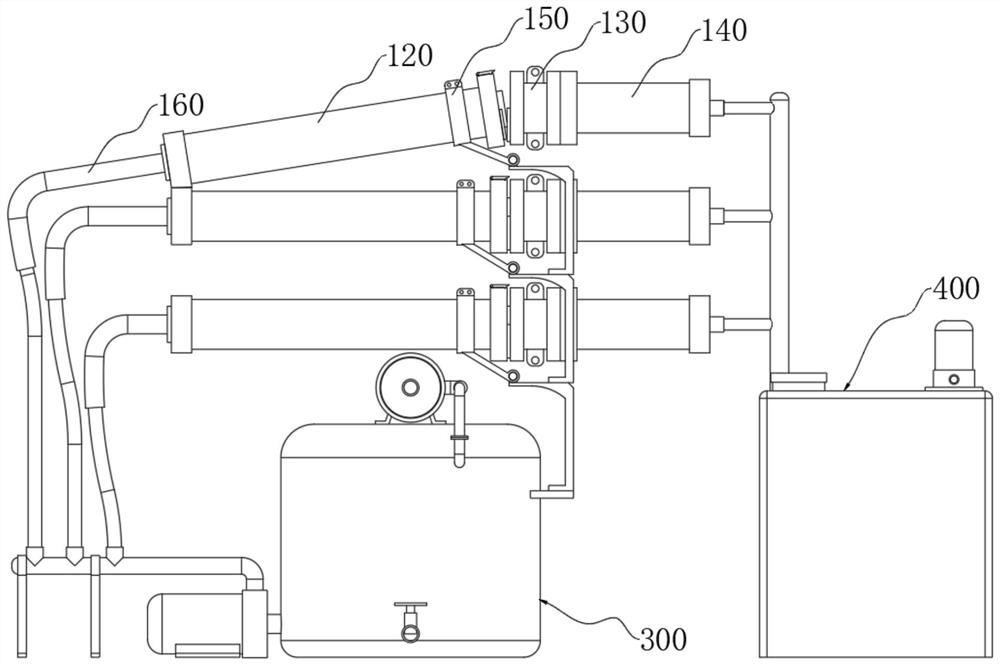

[0074] The invention provides a quick-dismantling decontamination method for a reverse osmosis water treatment pipeline, comprising the following steps:

[0075] 1. Quick disassembly and cleaning stage of reverse osmosis pipe:

[0076] S1, firstly press down the quick-release part 123 in the reverse osmosis water treatment pipeline cleaning device, and drive the locking tongue 126 to retreat and disengage from the left end positioning groove 131 of the reverse osmosis pipe 130;

[0077] S2, then rotate the reverse osmosis pipe 130 by 180 degrees to completely disengage the circular groove 133 from the semicircular ring 122, then unscrew the nut at one end of the circular ring at the bottom of the rotating rod 151, and press down the left end of the long seepage pipe 120, Separate its right end from the reverse osmosis pipe 130;

[0078] S3, take out the reverse osmosis pipe 130 again, and then clean the reverse osmosis diaphragm 135;

[0079] The reverse osmosis water treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com