Textile fabric dyeing equipment with cleaning and dust removing functions

A technology for dyeing equipment and textiles, applied in the field of textiles, can solve the problems of inability to synchronously clean and dedust, affect the dyeing effect, poor dyeing effect, etc., and achieve the effects of thorough cleaning process, good dyeing effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

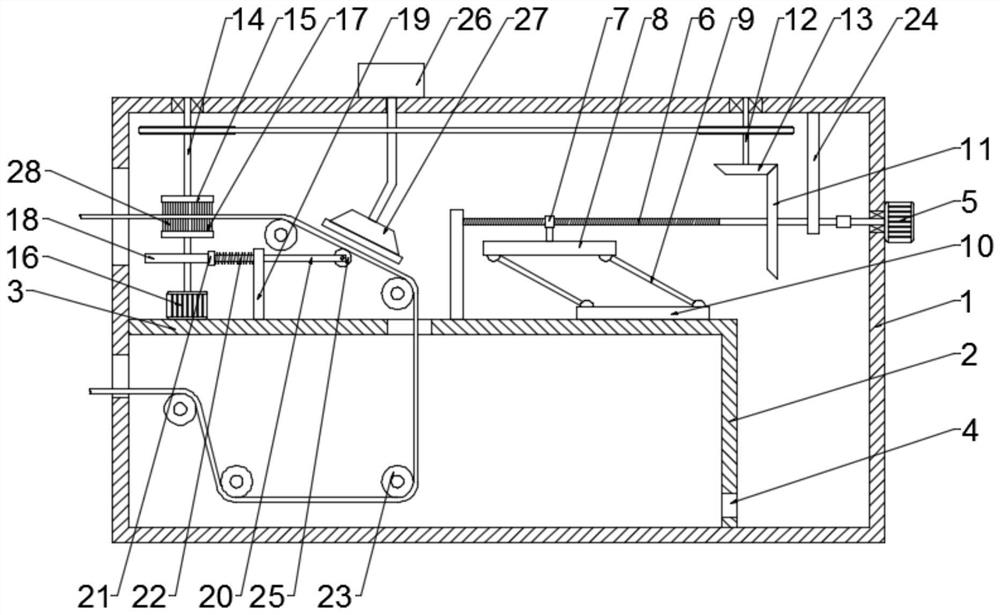

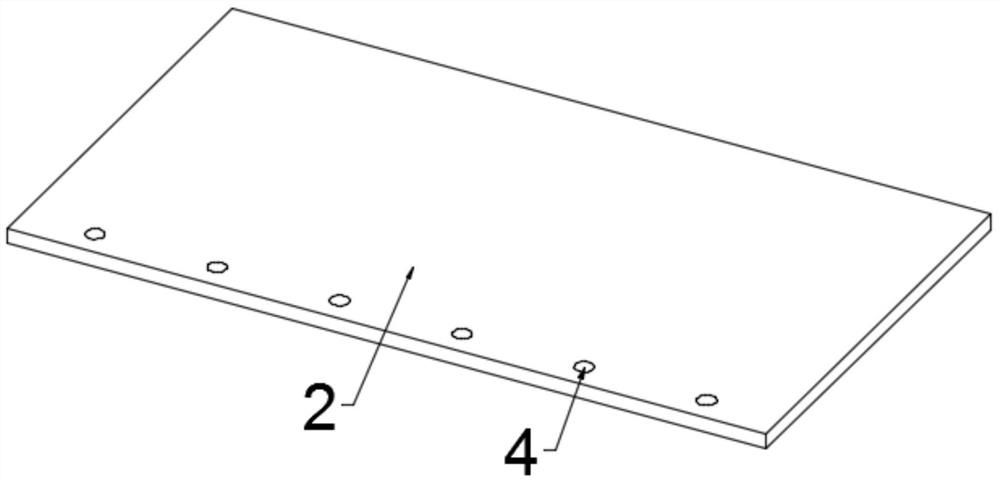

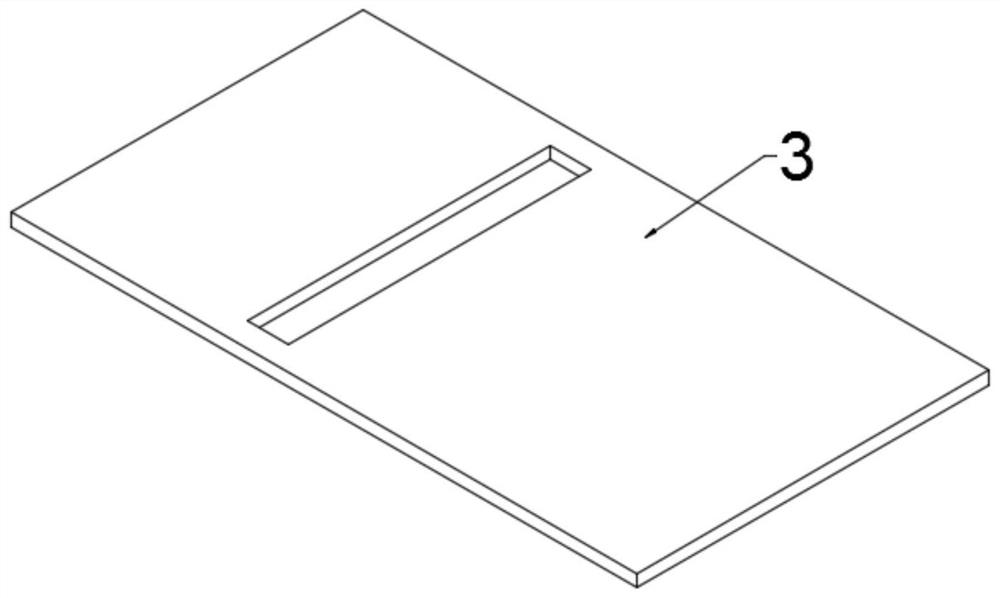

[0021] Example 1: Please refer to Figure 1-3 , a kind of textile dyeing equipment with cleaning and dust removal function, comprising an equipment box 1, a vertical partition 2 is fixedly connected to the right side of the equipment box 1, a horizontal partition 3 is fixedly connected to the top of the vertical partition 2, and the horizontal partition 3 A through hole 4 is opened at the bottom, a first motor 5 is fixedly connected to the right side of the equipment box 1, and a drive screw 6 is connected to the output end of the first motor 5 through the equipment box 1;

[0022] During use, the textile is moved through the inner side of the device through the guidance of the guide roller 23, the first motor 5 is turned on, and the rotation of the first motor 5 drives the driving screw 6 to rotate;

[0023] The outside of the drive screw 6 is threadedly connected with a drive sleeve 7, the lower part of the drive sleeve 7 is fixedly connected with an upper slide plate 8, and...

Embodiment 2

[0034] Example 2: Please refer to Figure 1-3 , a kind of textile dyeing equipment with cleaning and dust removal function, comprising an equipment box 1, a vertical partition 2 is fixedly connected to the right side of the equipment box 1, a horizontal partition 3 is fixedly connected to the top of the vertical partition 2, and the horizontal partition 3 A through hole 4 is opened at the bottom, a first motor 5 is fixedly connected to the right side of the equipment box 1, and a drive screw 6 is connected to the output end of the first motor 5 through the equipment box 1;

[0035] During use, the textile is moved through the inner side of the device through the guidance of the guide roller 23, the first motor 5 is turned on, and the rotation of the first motor 5 drives the driving screw 6 to rotate;

[0036] The outside of the drive screw 6 is threadedly connected with a drive sleeve 7, the lower part of the drive sleeve 7 is fixedly connected with an upper slide plate 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com