Powerful eddy pulse jet system for shield tunneling machine

A technology of eddy current pulse and jet system, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of affecting the driving efficiency, easily damaged cutterhead, hob and scraper, and affecting the working efficiency of the shield machine, so as to improve the Use efficiency and construction efficiency, reduce impact and wear, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

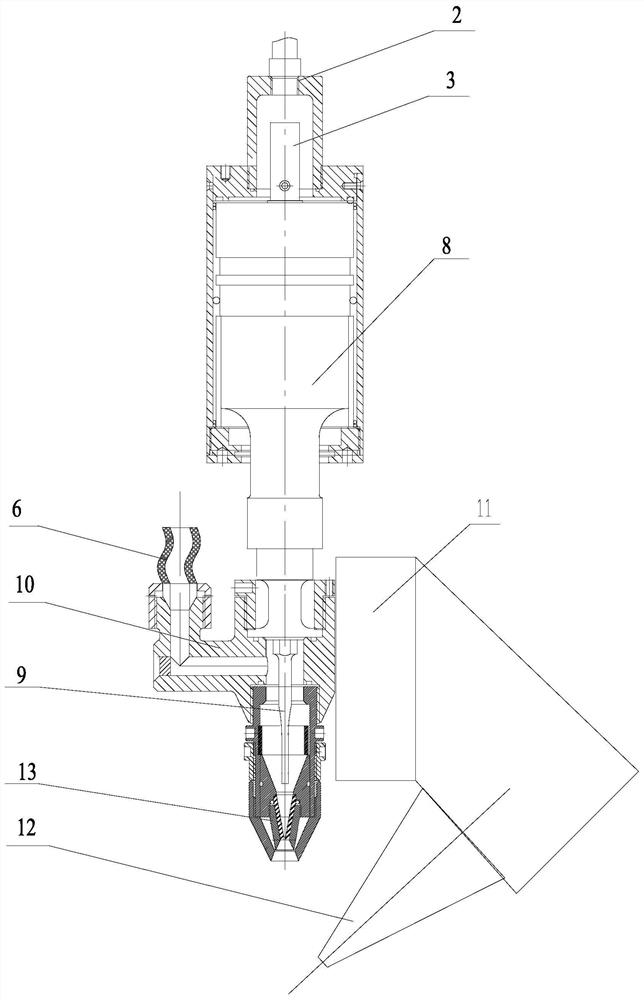

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

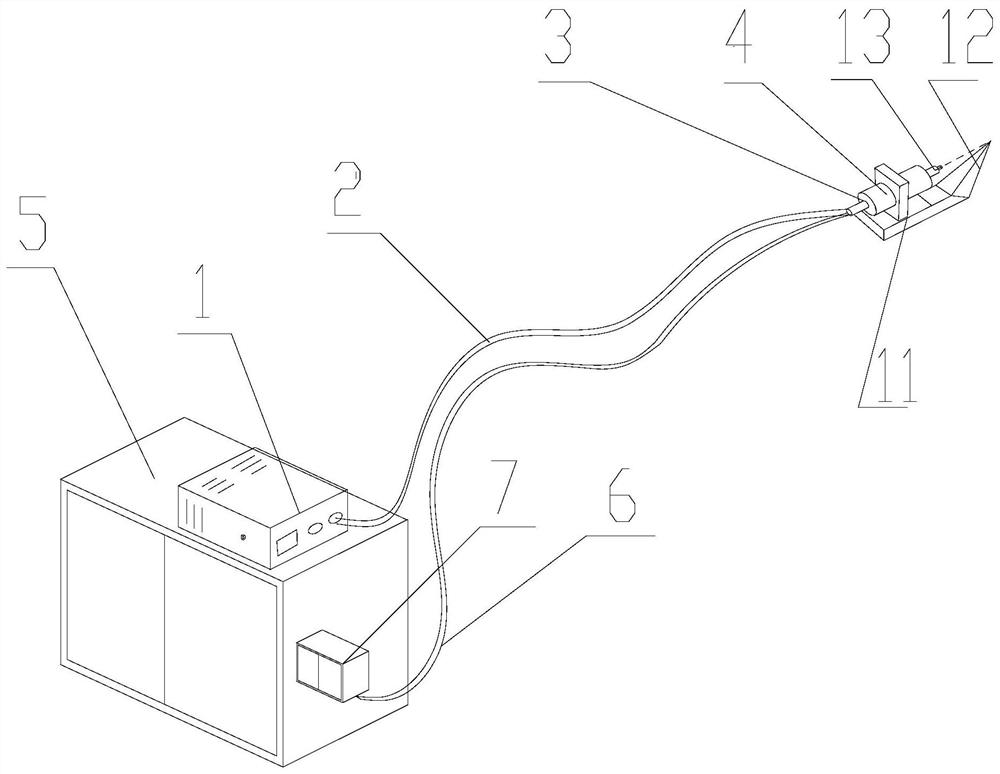

[0017] figure 1 , 2 Including eddy current pulse generator 1, pulse signal transmission cable 2, cooler 3, pulse jet nozzle device 4, high pressure water generating device 5, high pressure hose 6, pressure regulating valve 7, piezoelectric ceramic transducer 8, transformer Spindle 9, nozzle assembly 10, nozzle base 10-1, nozzle body 10-2, knife disc 11, scraper 12, nozzle 13, etc.

[0018] like figure 1 As shown, the present invention is a powerful vortex pulse jet system for a shield machine, including a high-pressure water generator 5 and a vortex pulse generator 1, and the vortex pulse generator 1 can be arranged on the top of the high-pressure water generator 5. The water generating device 5 adopts a three-plunger reciprocating high-pressure pump.

[0019] The high-pressure water outlet end of the high-pressure water generator 5 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com