A kind of preparation method for heating cigarette tobacco endogenous segment material and application thereof

A tobacco and endogenous technology, applied in the fields of application, tobacco, and tobacco preparation, to achieve the effects of improving stability, reducing drying conditions, and ensuring homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

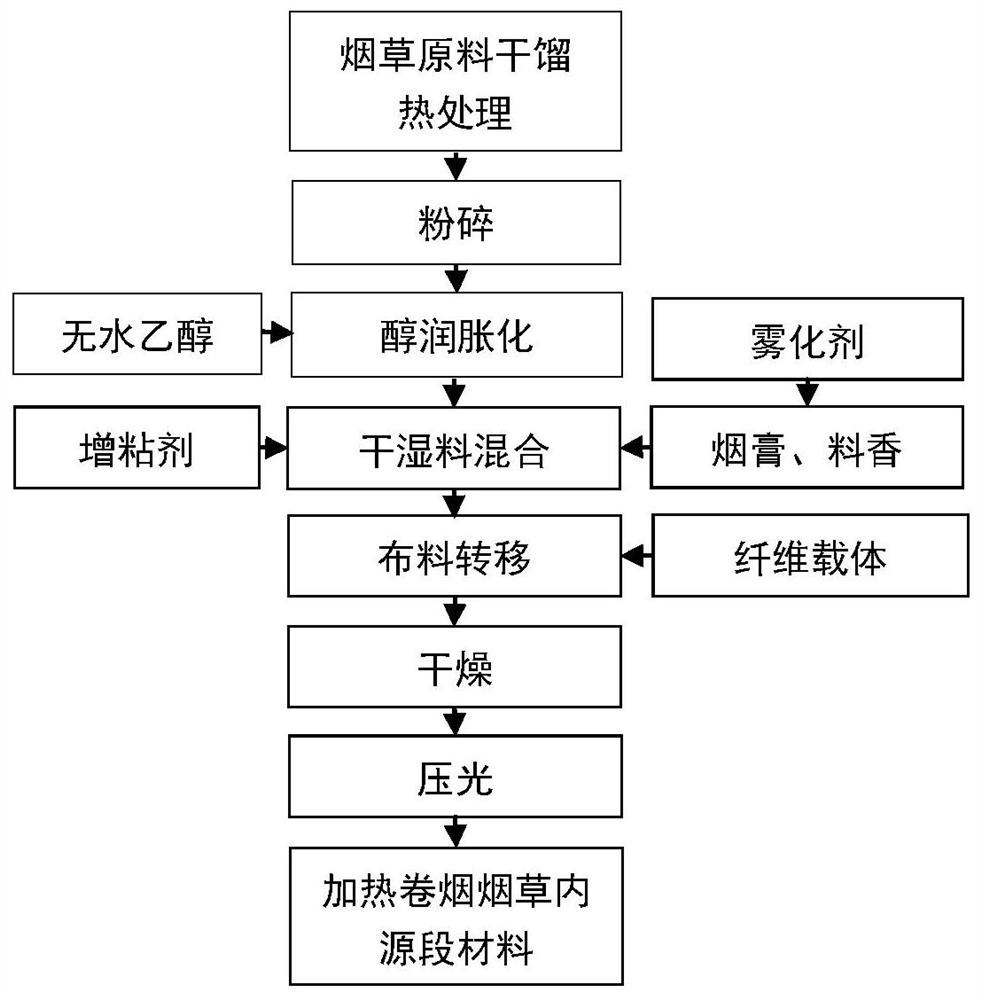

[0033] A preparation method suitable for heating cigarette tobacco endogenous section material, comprising the following steps:

[0034] (1) First, the raw materials of flue-cured tobacco, sun-cured tobacco and oriental tobacco are weighed according to the mass ratio of 7.8:1.2:1.0 and mixed, and then subjected to dry distillation heat treatment at 100-150°C. quality tobacco particles;

[0035] (2) fully mixing absolute ethanol and tobacco particles in the reactor and sealing and standing for 1 to 24 hours to obtain alcohol-swelled tobacco-based raw materials, and the mass ratio of tobacco particles to absolute ethanol is 5.0:0.5;

[0036] (3) Using glycerol and propylene glycol as atomizers in a mass ratio of 7:3, heating and dissolving beeswax at 60-70°C, and then adding potassium malate solution dissolved in absolute ethanol and polyvinyl alcohol for 0.5-1.0 h. , carry out the mutual emulsification reaction, and then seal and stand for 2h to form a stable atomized emulsion...

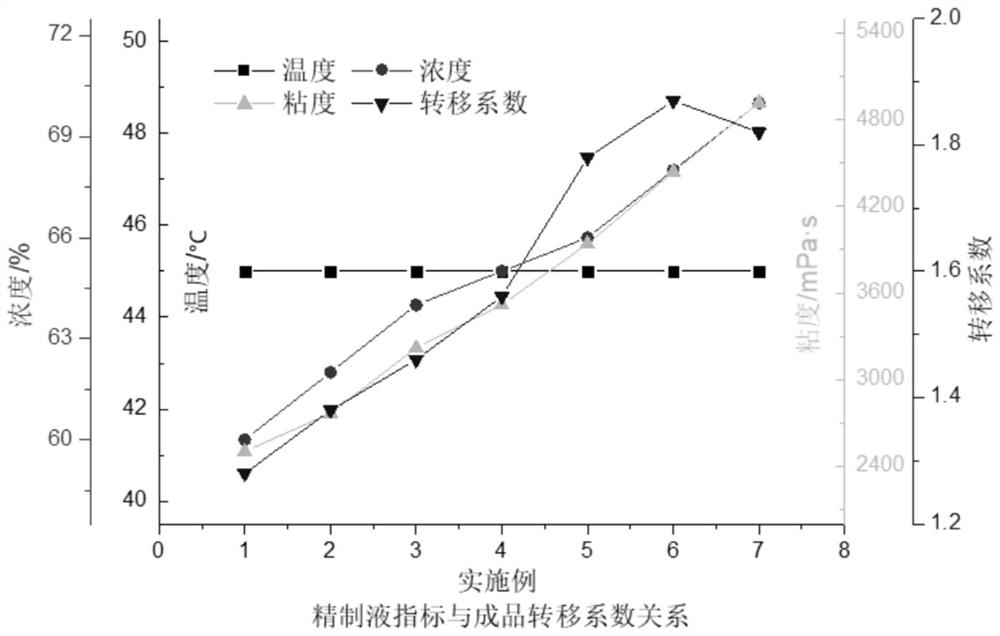

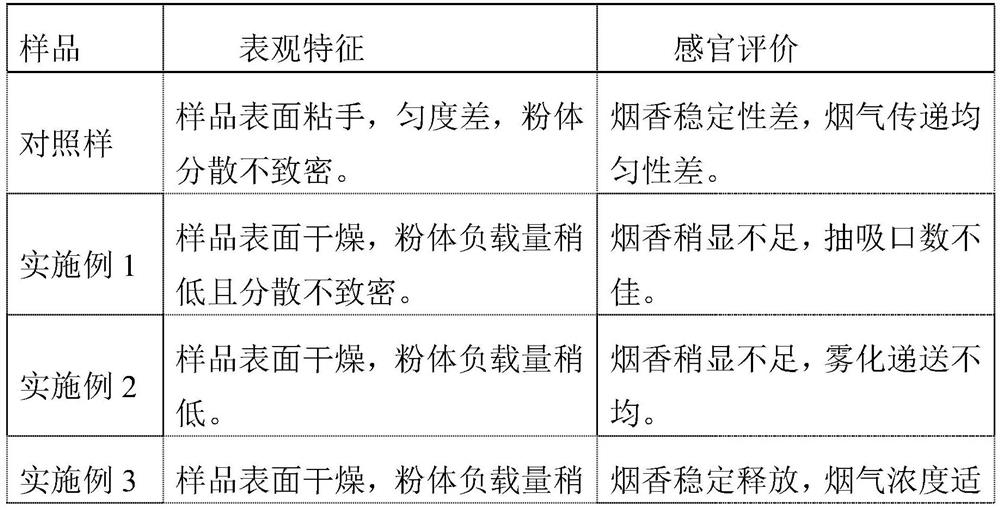

Embodiment 2~4

[0044] With embodiment 1, it is different from the amount of tackifier and the amount of tobacco particles. The ratio is as follows:

Embodiment 2

[0046] Mass ratio of tackifier and mixed wet material = 1.5:100.0

[0047] Mass ratio of tobacco particles to absolute ethanol = 6.0:0.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com