Diatomite/polypropylene blended hollow fiber membrane and preparation method thereof

A technology of diatomite and fiber membranes, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve problems such as low oil absorption rate, non-reusable use, complex components, etc., achieve excellent oil absorption rate and meet multiple cycles Effect of use, good porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

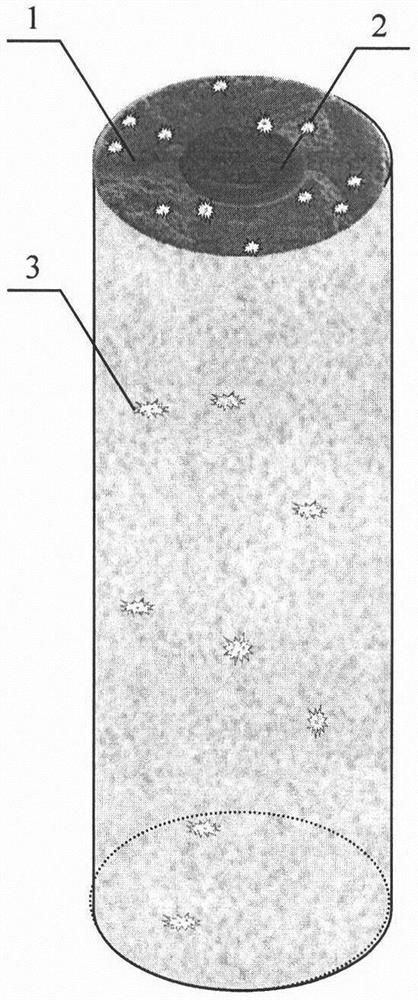

[0013] The invention provides a method for preparing a diatomite / PP blended hollow fiber membrane, comprising the following steps:

[0014] Step 1: Weigh the following raw materials according to mass percentage: diatomite 0-15%, PP85-100%.

[0015] Step 2: Mix the weighed diatomite and PP powder evenly in a high-speed mixer to obtain casting film powder.

[0016] Step 3: Put the casting film powder obtained in Step 2 into a twin-screw extruder, melt it, extrude it through a spinneret, draw it, and shape it to obtain a hollow fiber membrane.

[0017] Among them, the temperature of the extruder is controlled at 180°C, and the shaping includes two parts, heat treatment and stretching. Heat treatment: put the pulled film wire in an electric oven to improve the crystal structure; stretching: including cold stretching and hot stretching .

Embodiment 1

[0019] Weigh the following raw materials according to mass percentage: 50g of diatomite, 950g of PP, dry the materials in advance, mix the weighed materials evenly at high speed, add them to the twin-screw extruder, melt them, control the temperature at 180°C, and extrude them through the spinneret out, traction, and shaping to obtain a hollow fiber membrane. The prepared hollow fiber membrane was cast into a curtain membrane module with a porosity of 58.7%, immersed in the oil-water mixture, and after a period of adsorption, the measured oil absorption rate was 75.3%. After treatment, the backwash rate of the membrane module was 74%.

Embodiment 2

[0021] Weigh the following raw materials according to mass percentage: 100g of diatomite, 900g of PP, dry the materials in advance, mix the weighed materials evenly at high speed, add them to the twin-screw extruder, melt them, control the temperature at 180°C, and extrude them through the spinneret out, traction, and shaping to obtain a hollow fiber membrane. The prepared hollow fiber membrane was cast into a curtain membrane module with a porosity of 61.7%, immersed in the oil-water mixture, and after a period of adsorption, the measured oil absorption rate was 83.7%. After treatment, the backwash rate of the membrane module 85%.

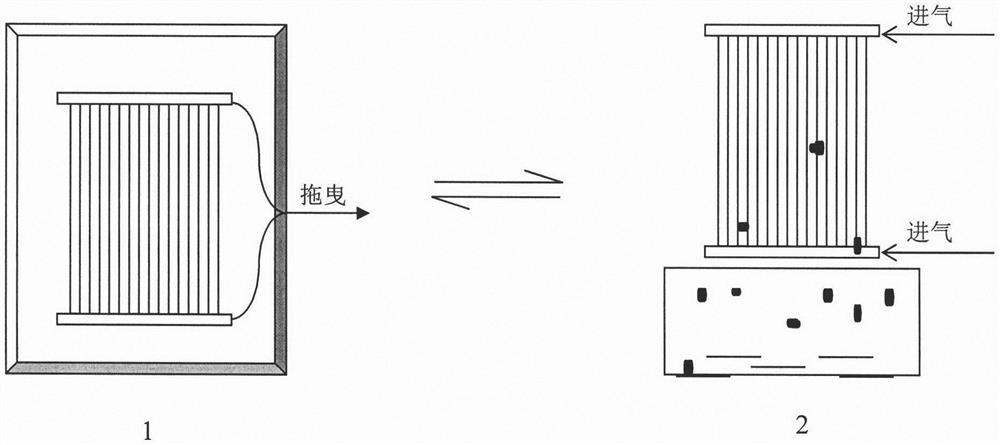

[0022] The present invention has carried out the oil-absorbing capacity test to the hollow fiber membrane that the embodiment makes: Seen device such as figure 2 . figure 2 Middle 1 is the oil-water mixing tank, which can absorb the oil by immersing the curtain membrane module, and 2 is the oil receiving plate, and the both ends of the curtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com