Local gas sealing device for additive and subtractive manufacturing

A technology of gas sealing, adding and subtracting materials, used in additive manufacturing, additive processing, engine sealing, etc., can solve the problems of large demand for materials, affecting processing accuracy and quality, and large gas demand, and achieves easy disassembly. The effect of installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

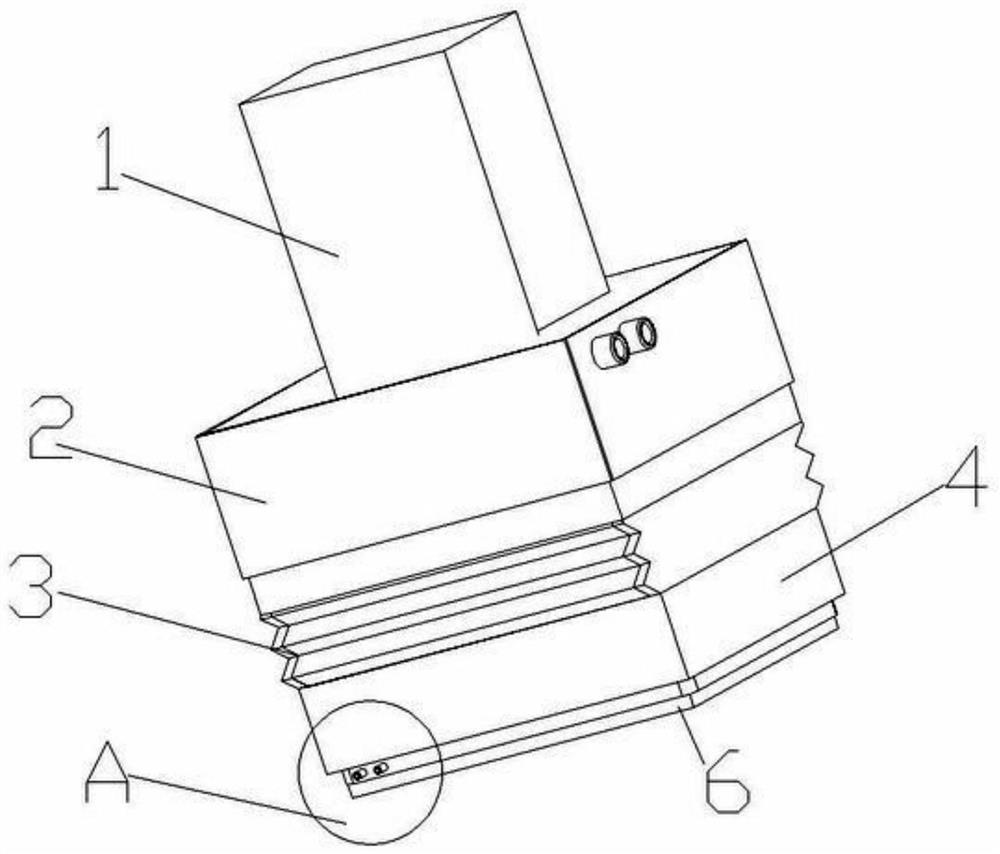

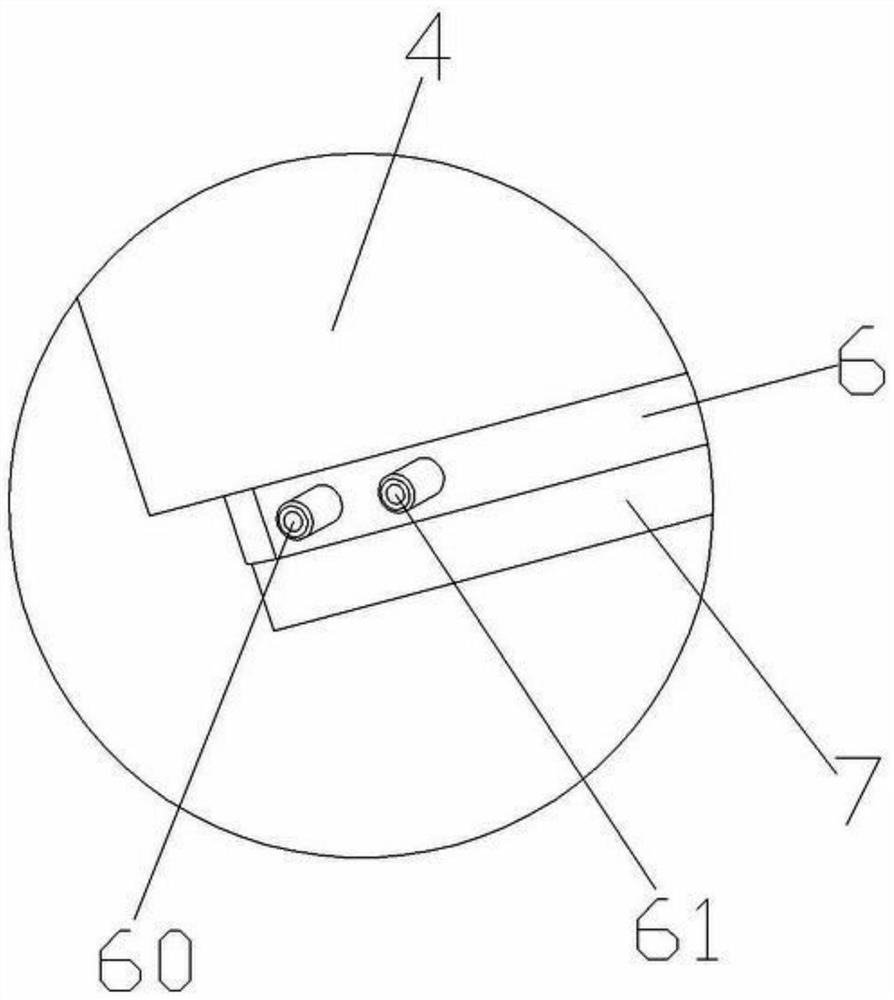

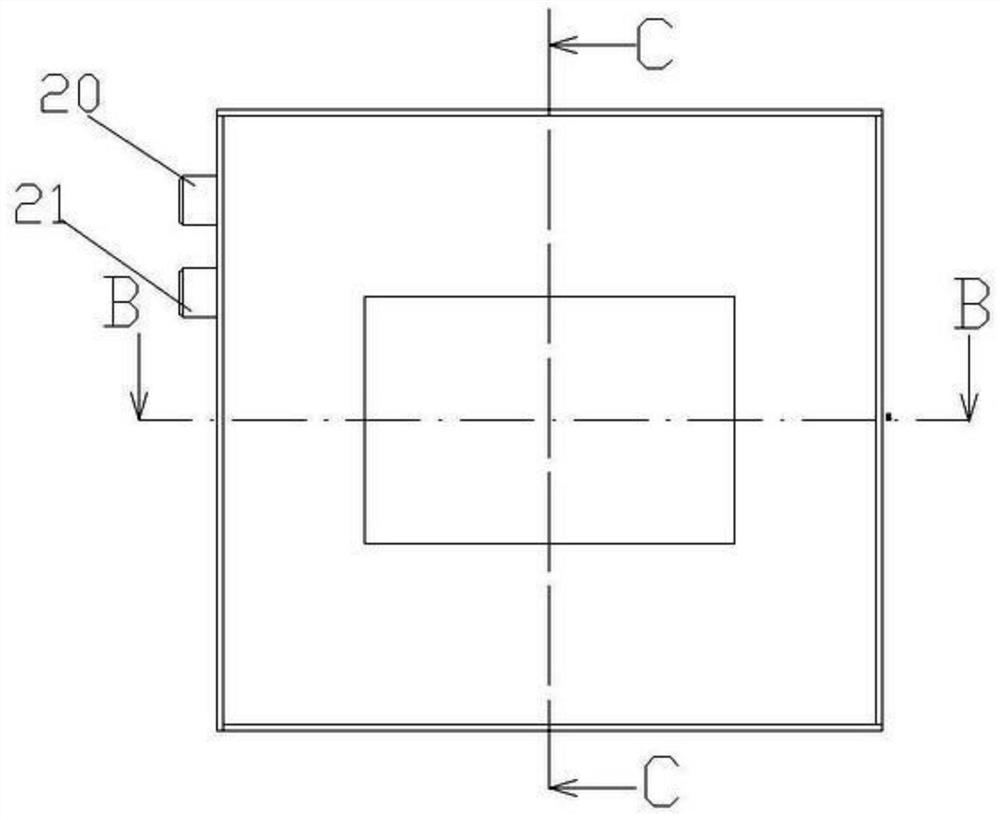

[0019] see Figure 1 to Figure 7 As shown, a local gas sealing device for adding and subtracting materials, including a fixed box 1, the fixed box 1 is fixed on the slide plate of the machine tool, and the slide plate drives the fixed box 1 to perform X, Y and Z on the machine table 7. direction, the fixed box 1 is a cavity structure with one end open, and the fixed box 1 is equipped with a movable laser cladding head and a welding torch. 2 The flexible sealing cover 3 with two-way openings is fixedly connected to the lower sealing cover 4, and the bottom edge of the lower sealing cover 4 is provided with a sealing air bag 6 that can deform inwardly and match the embedded groove of the machine tool table;

[0020] The upper end of the fixing box 1 is provided with a wire hole through which the laser cladding head and welding torch cables can pass;

[0021] On any non-adjacent side surface of the inner side wall of the upper sealing cover 2, two driving assemblies 5 for contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com