Large-pipe-diameter large-thickness high-strength steel cylinder welding process

A high-strength steel, welding process technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as the accuracy of the cylinder body not up to standard, to ensure the flatness and verticality, ensure the accuracy of components, The effect of ensuring structural accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: 40mm thick EH36 diameter 3.6m crane cylinder welding

[0035] (1) Remove rust, oil, cutting slag, scale, moisture, etc. within 30mm of the groove and both sides of the groove surface before welding.

[0036] (2) Tack welding and temporary spot welding The weld seam and the base metal are smoothly transitioned, the length of the tack welding is 40-60mm, and the spacing is 200-250mm. The thickness of tack welding is not less than 1 / 3 of the thickness of the cylinder.

[0037] Before welding, use a heating plate to preheat the 200mm range of the weld seam area, and the preheating temperature is greater than 100°C. Welding is performed after the preheating area meets the temperature requirements.

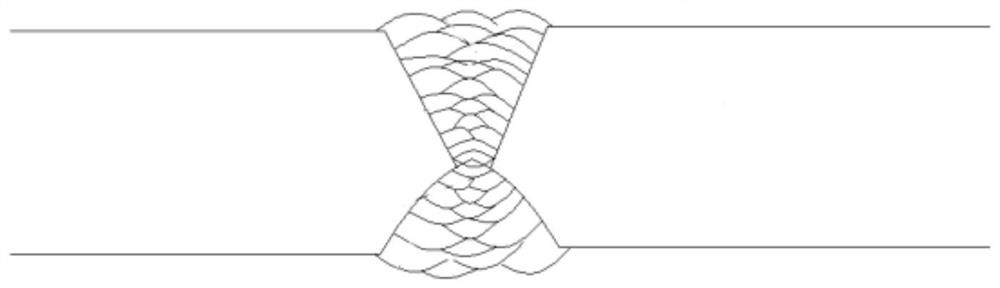

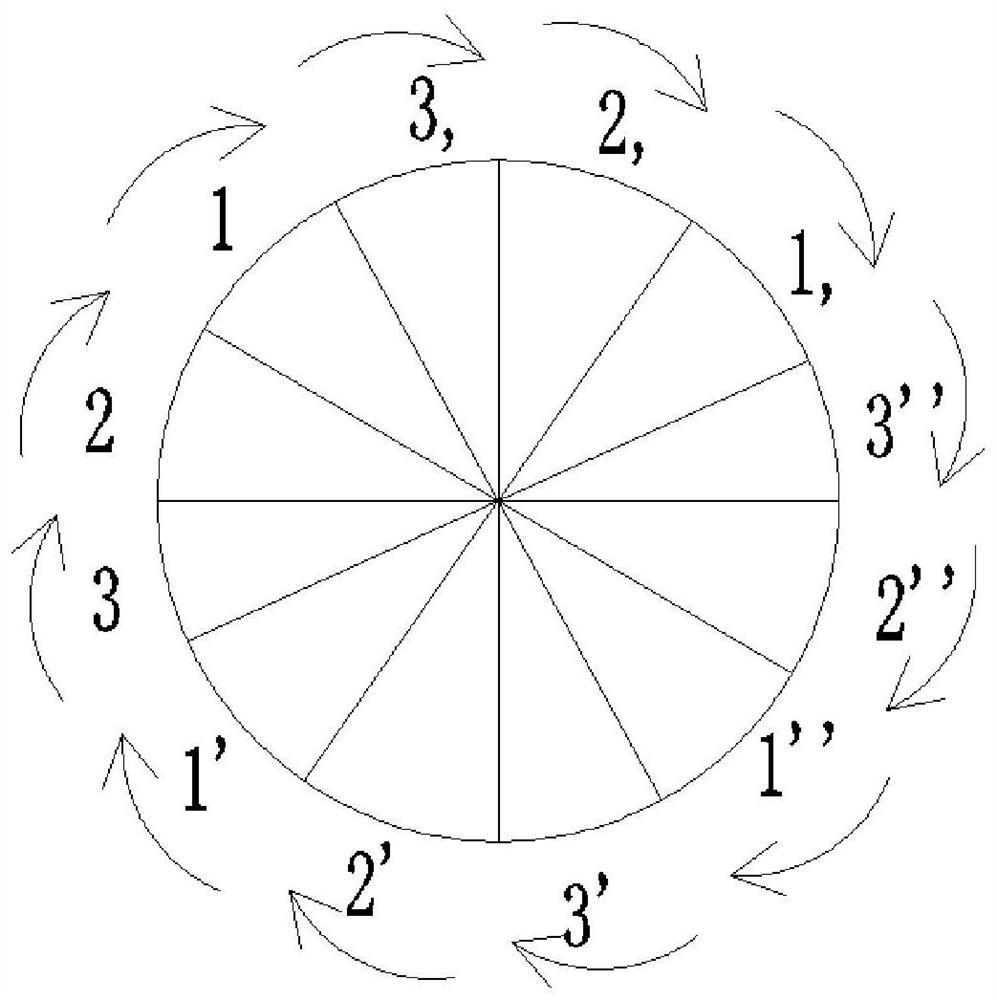

[0038] (3) Two welders are used to weld along the same direction, and the circumferential weld of the cylinder is divided into 18 sections according to each section of about 600mm. See figure 1 , using TWE-71Ni welding wire, welding current 180-220, voltage 27V, we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com