A kind of zinc-based high-temperature lead-free solder and production method thereof

A lead-free solder, production method technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of poor wettability and spreadability, difficult to apply welding of fuse tube electronic components, easy oxidation and so on , to achieve the effect of good welding reliability, stable quality and smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

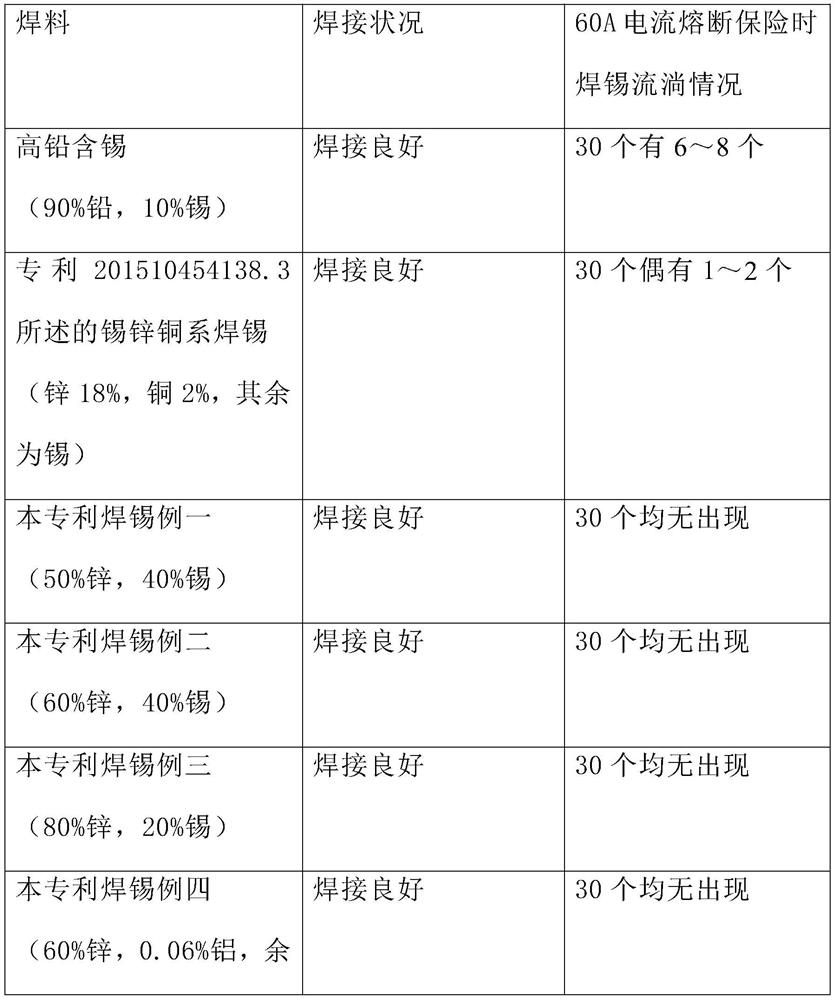

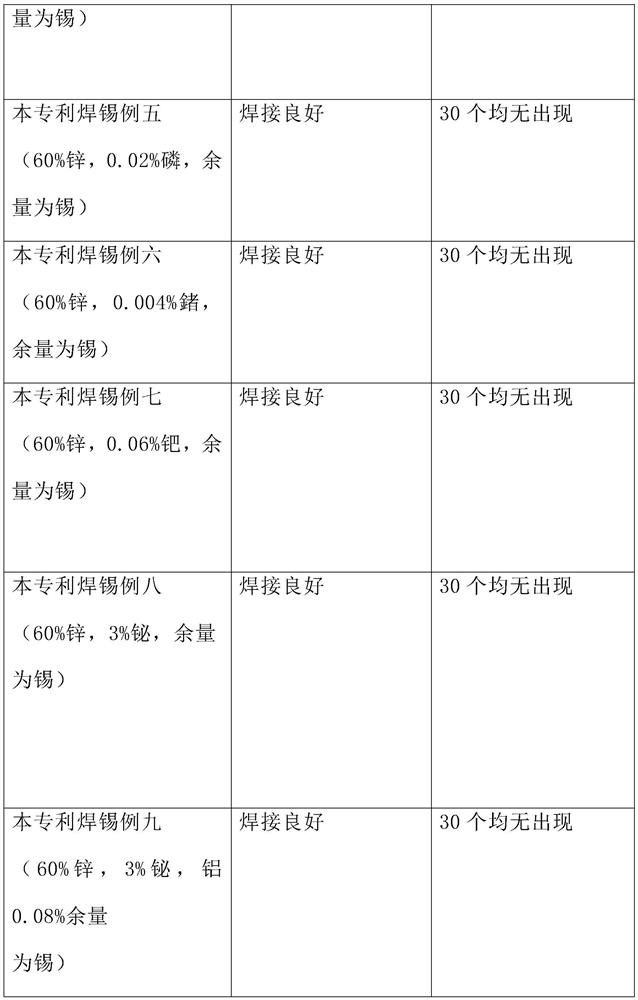

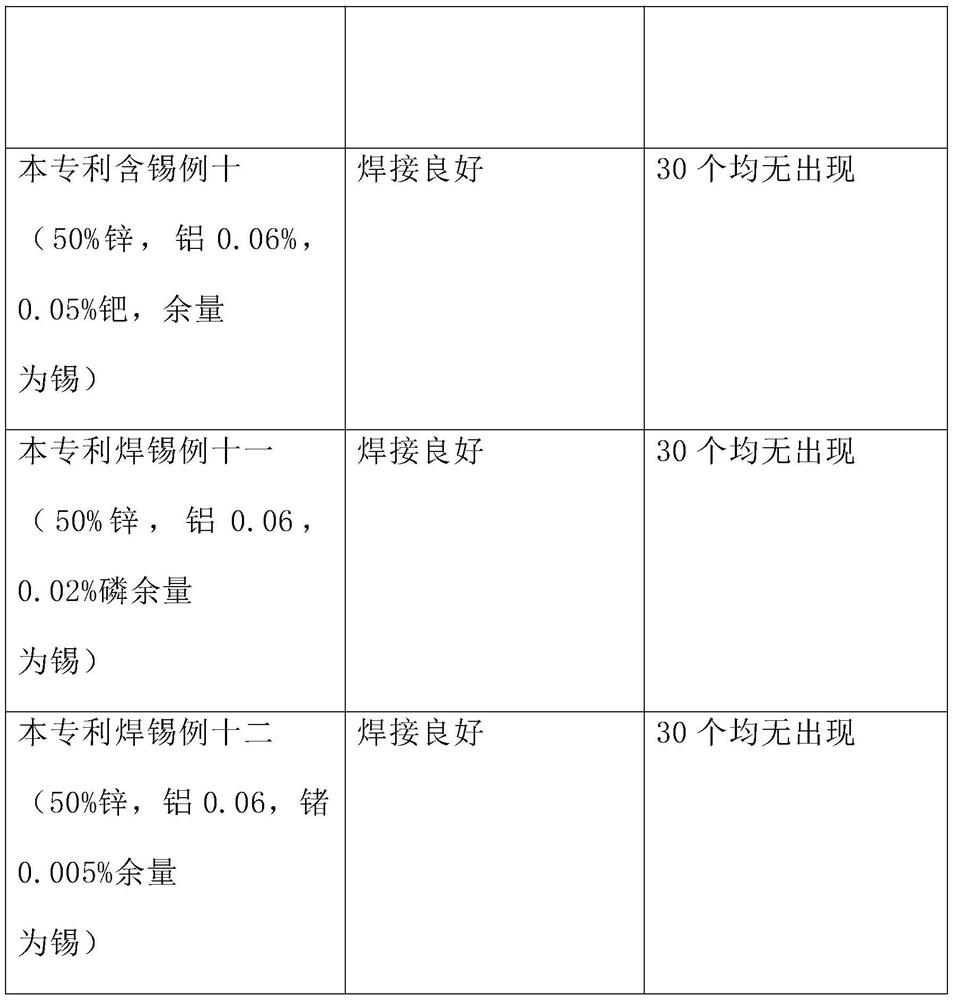

[0021] In order to further explain the technical solutions of the present invention, the present invention will be described in detail below through specific embodiments.

[0022] The invention discloses a zinc-based high-temperature lead-free solder, which contains 50% to 80% by weight of zinc, and also contains any one or any two of aluminum, bismuth, palladium, nickel, germanium or phosphorus. As additional trace elements, the weight percentages of the above-mentioned additional trace elements are: aluminum 0-0.09%, bismuth 0-3%, palladium 0-0.08%, nickel 0-0.05%, germanium 0-0.006% or phosphorus 0-0.03% %, the remainder is tin. Among them, the composition ratio of zinc and tin is designed to achieve the liquidus point of the solder required for a large rated current fuse tube in a more suitable temperature range of 355-385°C.

[0023] Further, the weight percentage of aluminum may be 0.01-0.09%. The weight percentage of bismuth may be 0.6-3%. The weight percentage of pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com