Slagging and slagging method for high-temperature alloy short-electrode electroslag furnace

A high-temperature alloy and short electrode technology is applied in the field of slag addition in electroslag furnaces, which can solve problems affecting alloy quality, arc breaking alloy quality, arc breaking, etc., and achieve the effects of reducing slag-forming time, reducing reaction time, and preventing difficult melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

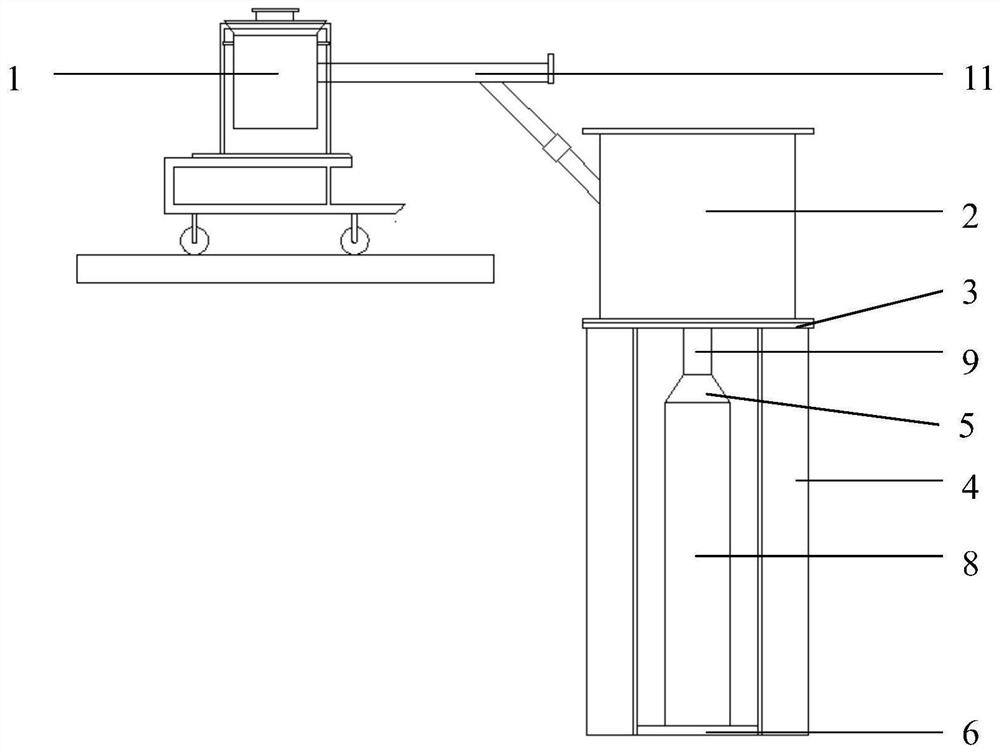

Embodiment 1

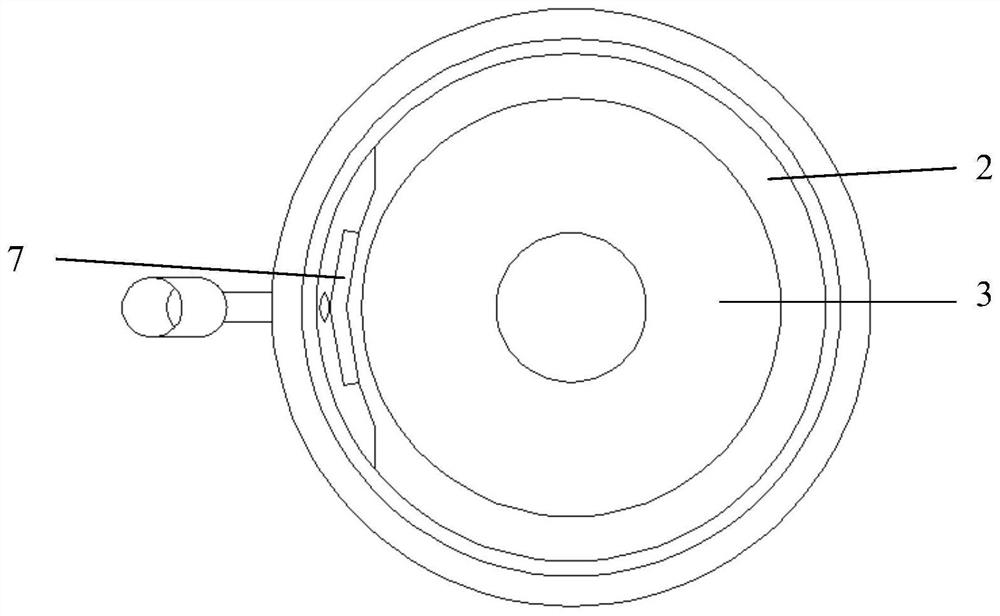

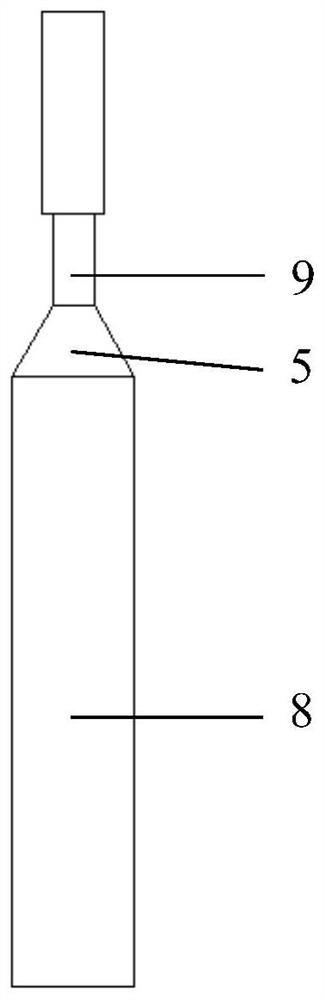

[0029] A slag adding and slagging method for a high-temperature alloy short-electrode electroslag furnace. The slag material is placed in the slag adding machine 1, the slag adding machine is started, and the slag material enters the lower fume hood 2 along the slag adding pipe 11, and then reaches the lower part of the method. Lan 3, and gather and align on the lower flange 3, enter the crystallizer 4, flow through the electrode cap 5, and finally reach the bottom pad 6, start slagging, the steps are as follows:

[0030] Initial stage of slagging: In the initial stage, use 7831A current for 1.1min temperature rise and preheating, then add slag at a speed of 1.0kg / min for 3.0min; then increase the current to 7904A, increase the slag adding speed to 1.5kg / min, and add slag at 5.0 min, the initial stage of slagging ends;

[0031] Slagging stable period: during the stable period, increase the current to 13078A, add slag at a slagging rate of 2.0kg / min for 4.9 minutes, then stop a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com