Assembly type cable-supported concrete transfer layer structure and construction method thereof

A construction method and concrete technology, applied to building components, building structures, walls, etc., can solve problems such as no particularly effective prefabricated construction schemes, and achieve the effect of ensuring assembling, rationality, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

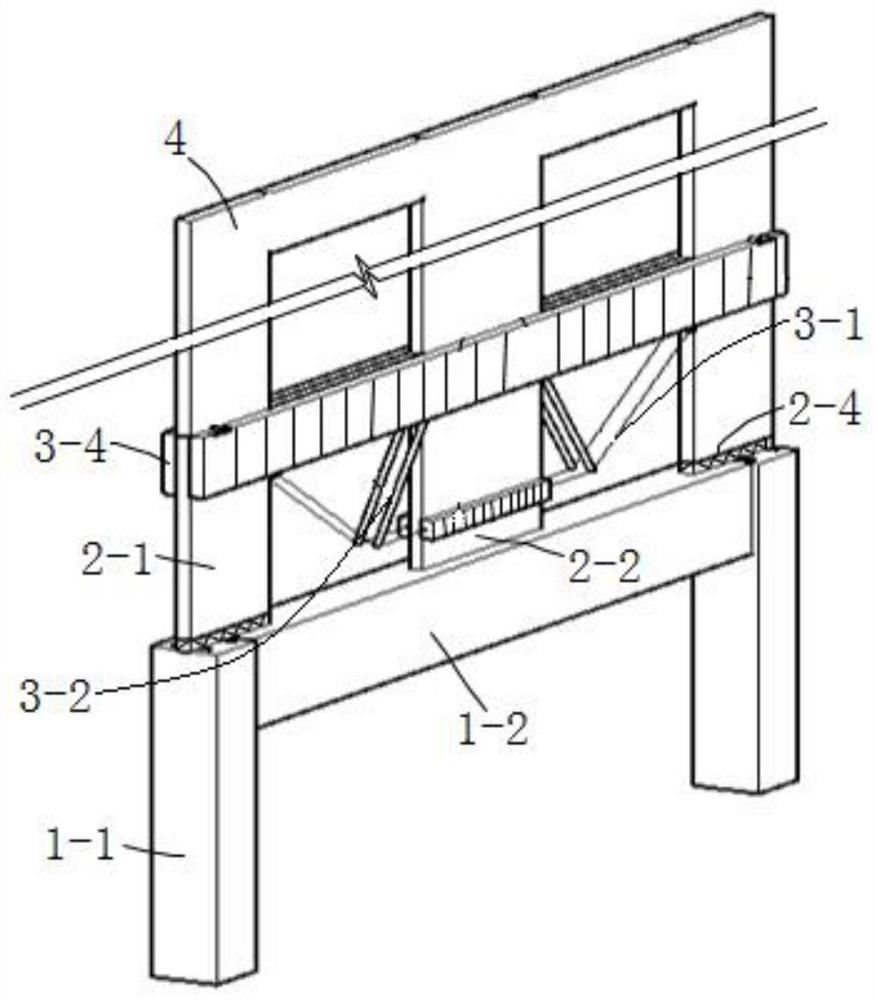

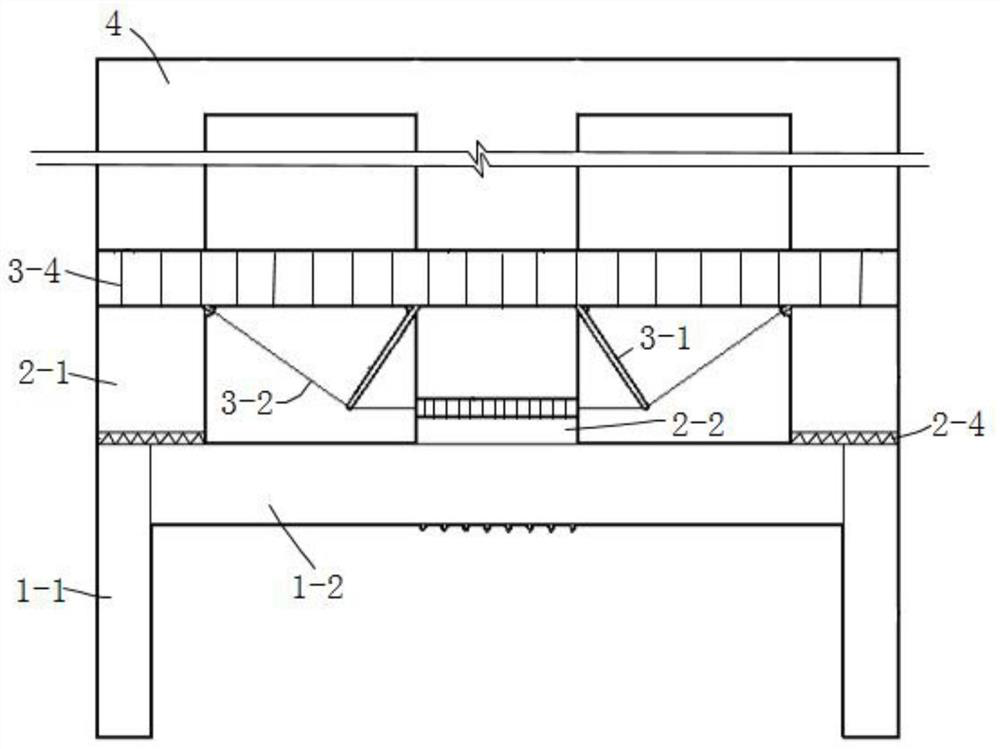

[0042] In order to solve the defects existing in the existing prefabricated structure, the embodiment of the present invention provides a prefabricated suspensive concrete transfer layer structure, such as figure 1 and 2 As shown, including frame support mechanism, concrete member and string support mechanism.

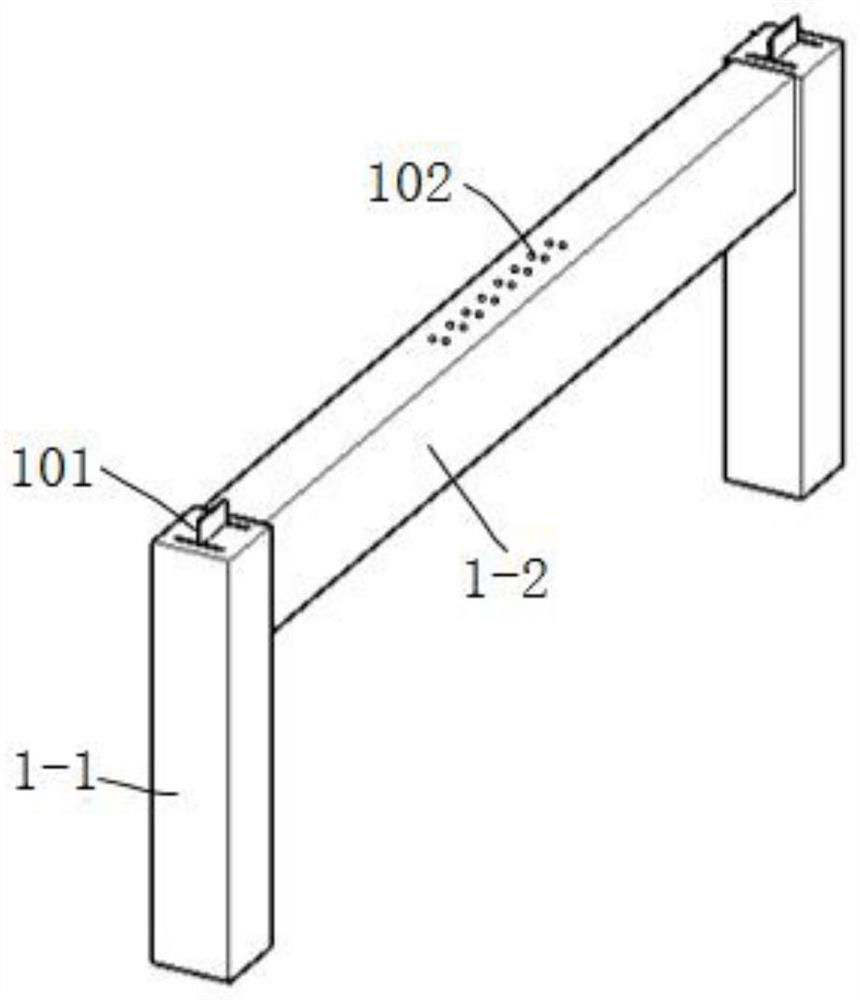

[0043] In this example, if image 3 As shown, the frame support mechanism is composed of two vertical frame pillars 1-1 and a frame support beam 1-2 connected to the top of the two frame pillars 1-1.

[0044] In order to fix the concrete member, the top ends of the two frame pillars 1-1 in this embodiment are provided with upper connectors 101, and several connection holes 102 are reserved on the frame support beam 1-2; specifically , the upper connector 101 is a steel plate, the upper connector 101 is formed by an I-shaped steel plate embedded in the frame pillar 1-1, and the I-shaped steel plate extends along the height direction of the frame pillar 1-1 and Go thr...

Embodiment 2

[0058] A construction method for a prefabricated suspensive concrete transfer layer structure, comprising the following steps:

[0059] (1) Install the fixed frame pillar 1-1 and the frame support beam 1-2, and set a temporary support on the lower side of the middle part of the frame support beam 1-2;

[0060] (2) Lift the concrete member to the top of the frame support mechanism as a whole, connect and fix the upper connector 101 and the lower connector 201 by bolts, pass the connecting rib 202 through the connecting hole 102, and pass the connecting rib 202 through the opening of the connecting hole 102 The end is fixed by a fixing sleeve, and then concrete is poured at the junction of the upper connector 101 and the lower connector 201 to form the lower post-casting area 2-4 of the transfer layer;

[0061] (3) Install the upper floor members 4 layer by layer above the concrete members using the connection method of conventional prefabricated structures;

[0062] (4) After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com