Lateral-force-resistant damper and steel frame combined structure and manufacturing method thereof

A combined structure and damper technology, which is applied to building components, building structures, earthquake resistance, etc., can solve problems such as poor strength and complex assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

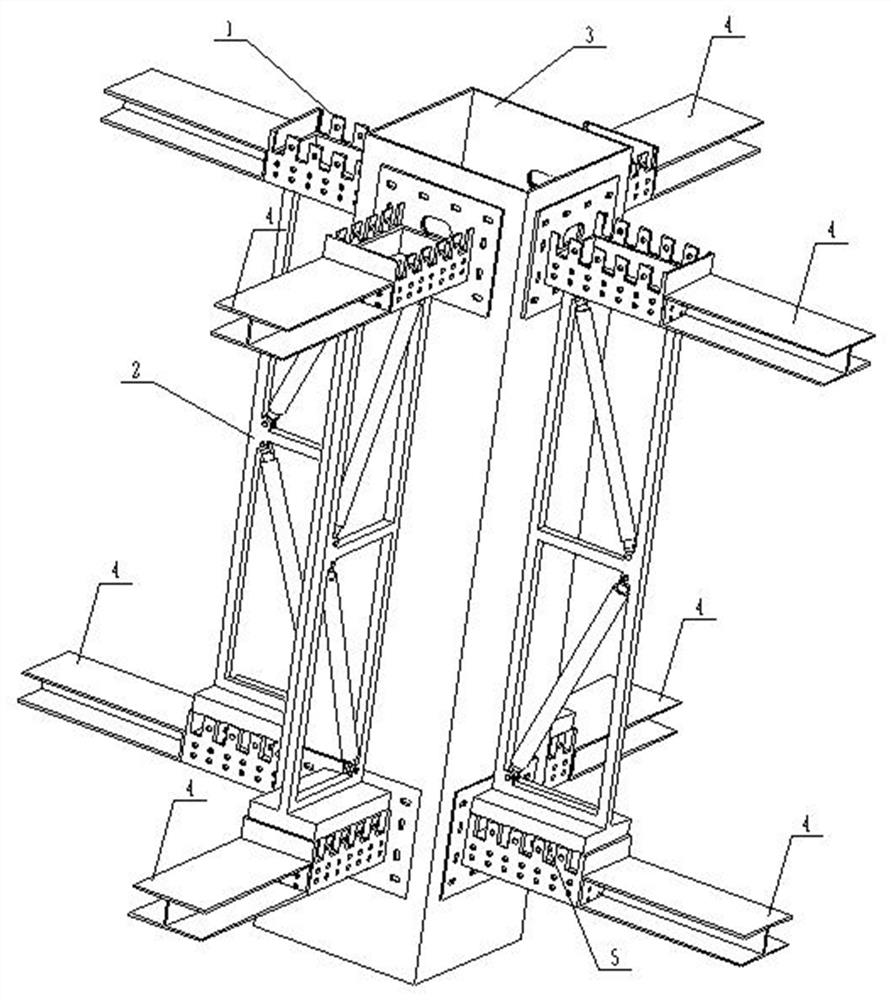

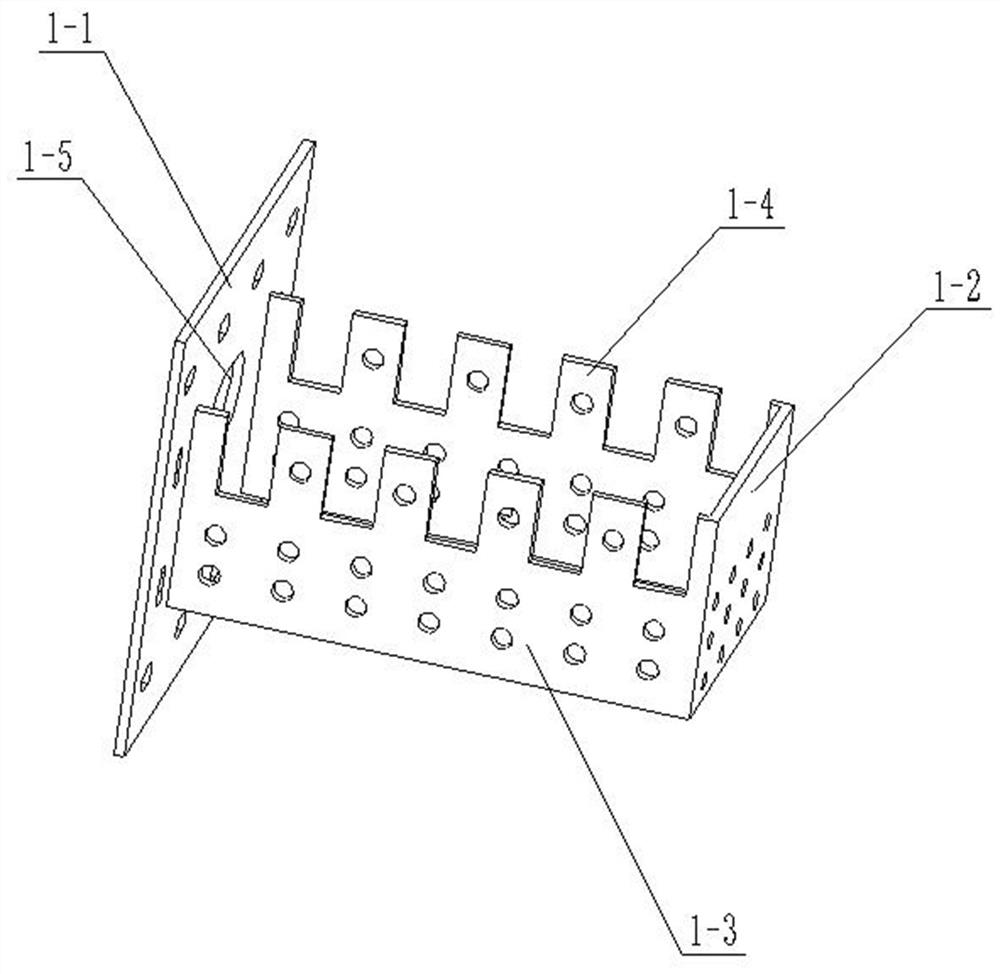

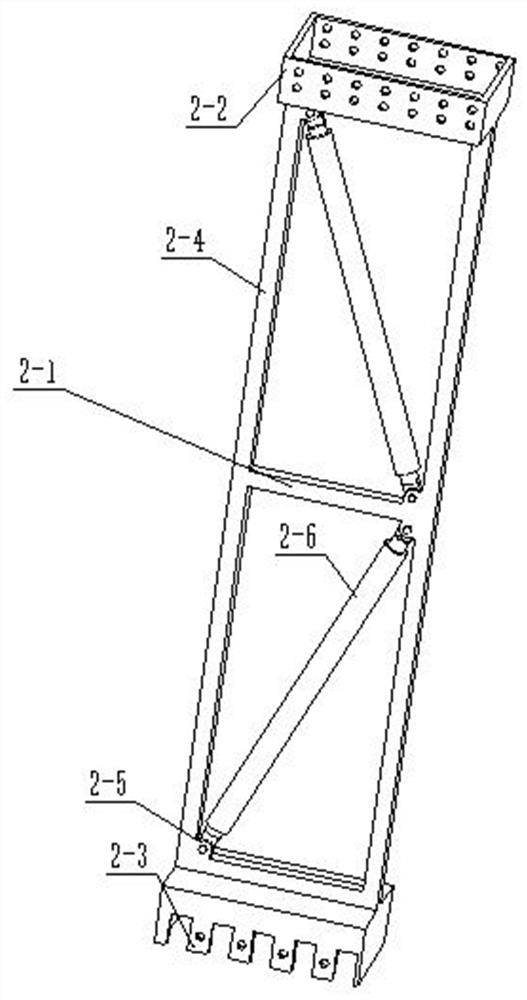

[0022] Such as Figure 1-4 As shown, the present invention provides a combined structure of an anti-lateral force damper and a steel frame, which includes a vertically penetrating square column (3), and a number of cantilever beams (1) are arranged at intervals along the length direction on the outer surface of the column. Via holes and through holes are provided on the mating surface of the beam, and nuts are pre-welded inside the via holes. The cantilever beam is a steel structure that penetrates up and down. The steel structure is welded by a fixed plate (1-1), a connecting plate (1-2), and a matching plate (1-3). The fixed plate corresponds to Set via holes and through holes (1-5) at the position, and fix the connection with the nuts pre-welded on the inner side of the column through bolts; set via holes on the connecting plate, weld the nuts in advance at the corresponding positions of the via holes, and pass the bolts at the end of the beam (4) It is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com