Appearance defect intelligent detection method and system based on machine vision

A technology for appearance defects and intelligent detection, which is applied in the direction of optical testing flaws/defects, instruments, measuring devices, etc. It can solve the problems of high rate of missed detection and false detection, detection standards are affected by personal subjective factors, and high labor costs, so as to improve detection Efficiency, reduction of missed detection and false detection rate and labor cost, and improvement of production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

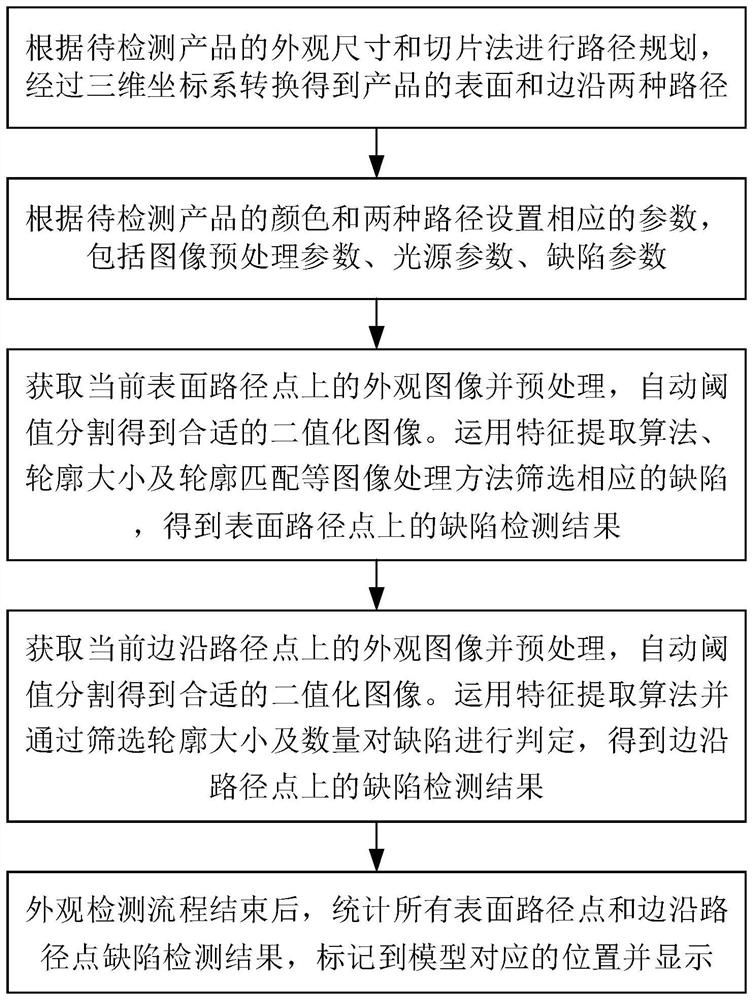

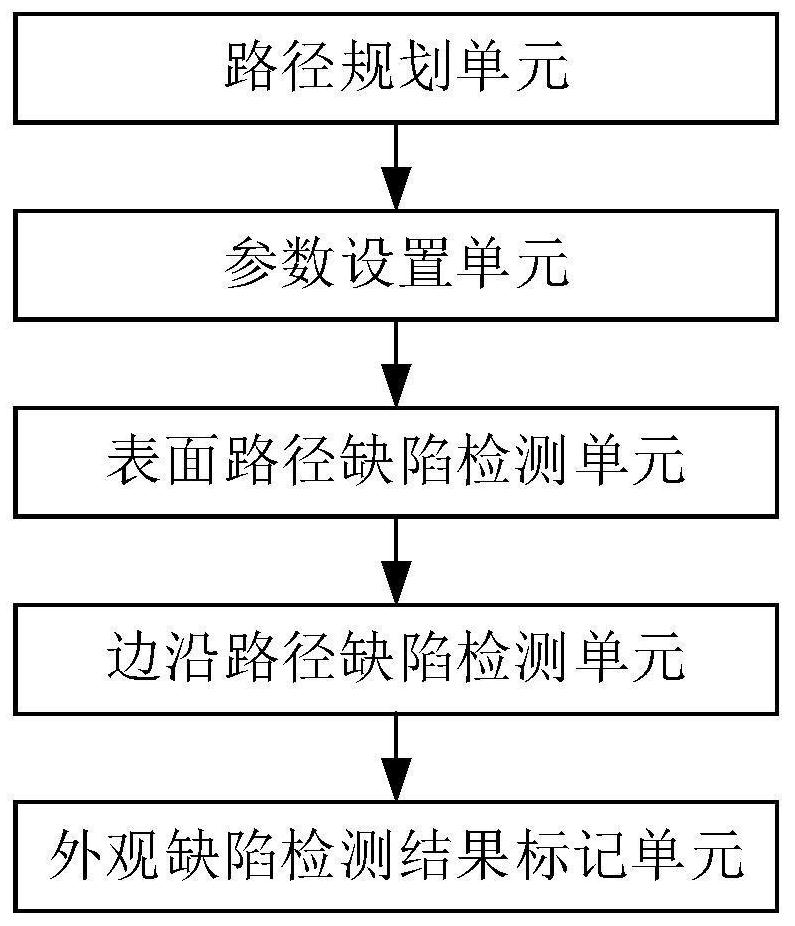

[0052] as attached figure 1 , 2 As shown, an intelligent detection method and system for appearance defects based on machine vision, the intelligent detection system for appearance defects includes a path planning unit, a parameter setting unit, a surface path defect detection unit, an edge path defect detection unit, and an appearance defect detection result mark unit, which includes the following steps:

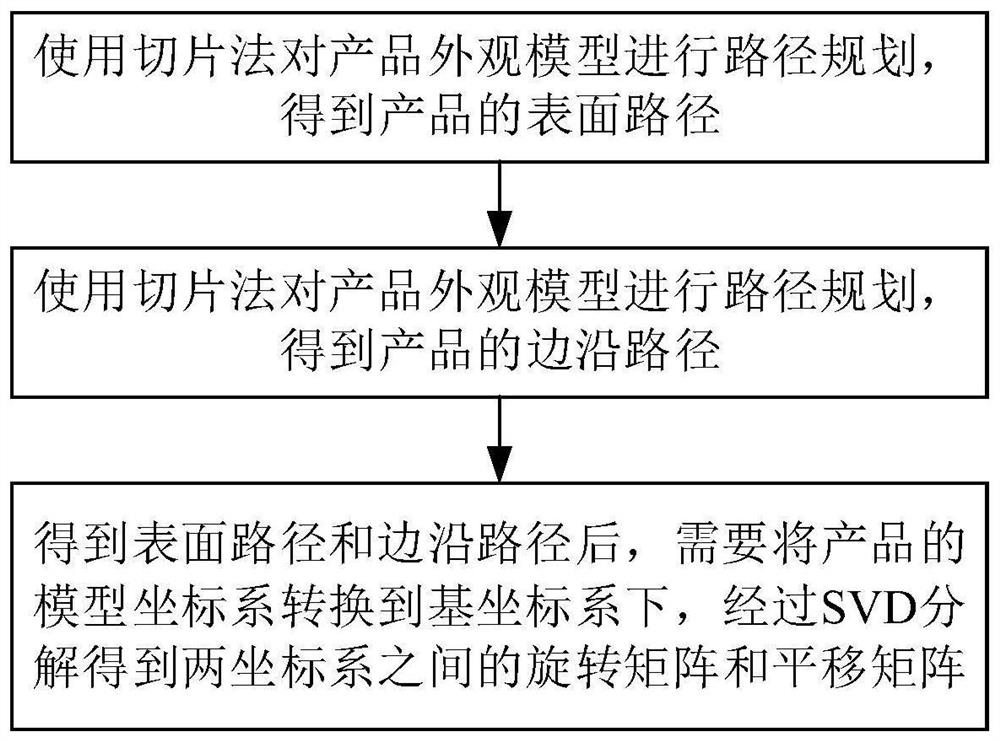

[0053] Step 1: Path planning unit: carry out path planning according to the appearance size of the product to be inspected and the slicing method, and obtain two paths of the surface and the edge of the product through the transformation of the three-dimensional coordinate system;

[0054] Step 2: Parameter setting unit: Set corresponding parameters according to the color of the product to be inspected and two paths, including image preprocessing parameters, light source parameters, and defect parameters;

[0055] Step 3: Surface path defect detection unit: Obtain the app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com