Condensation heat transfer performance characterization device

A technology for heat transfer performance and characterization, which is applied in the field of condensation heat transfer performance characterization devices, can solve the problems of large heat loss, narrow control range of steam temperature zone, and difficult to control the content of extremely low non-condensable gas, so as to reduce heat loss. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

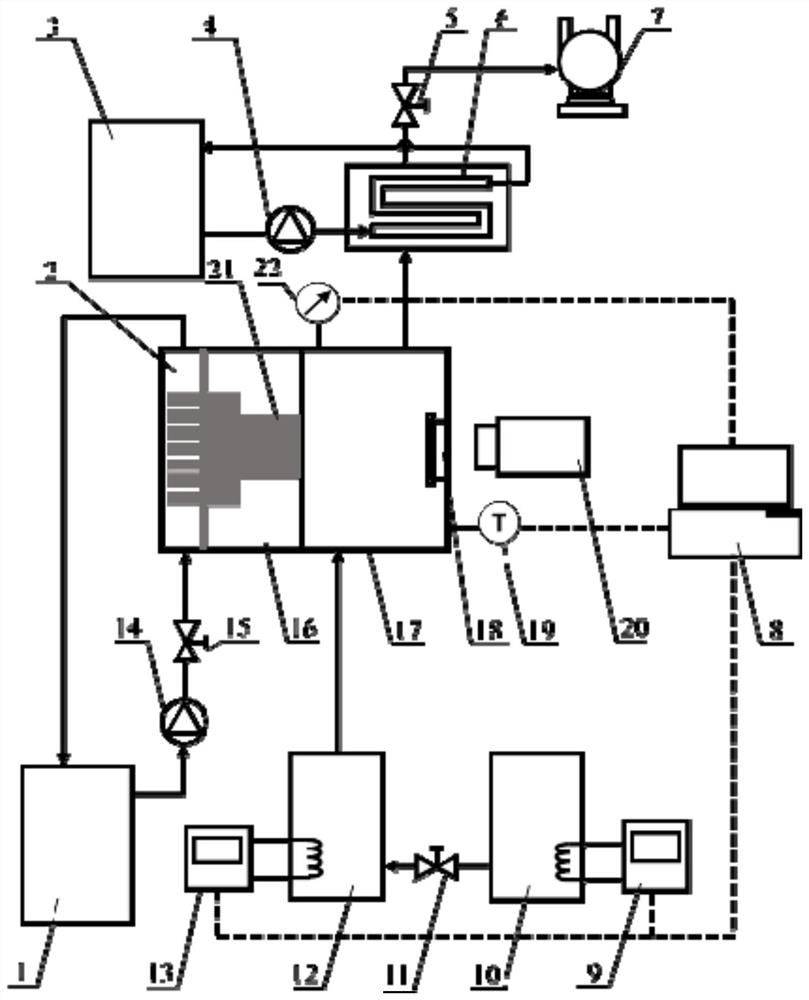

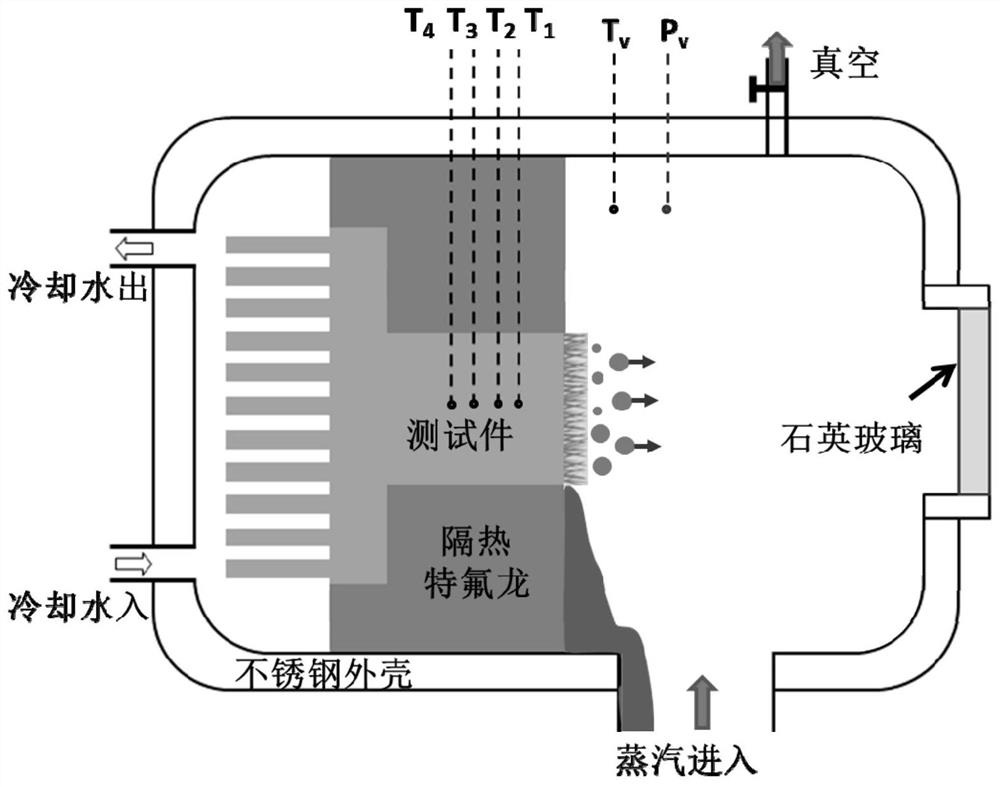

[0085] For the pure steam condensation heat transfer experiment, the technical solution is: first close the vacuum connection valve 11 between the main heating boiler 12 and the auxiliary heating boiler 10 of the steam generation unit, open the vacuum pipe joint 5 on the condensation pressure drop unit, and turn on the vacuum pump 7 Vacuumize the system to remove non-condensable gases in the system, add deionized water to the auxiliary heating boiler 10 of the steam generating unit, heat and boil for 30 minutes, and lower the water temperature to the preset steam temperature value. After vacuuming to the limit of the vacuum pump, close the vacuum pipe joint 5, open the vacuum connection valve 11 between the main heating boiler 12 and the auxiliary heating boiler 10 of the steam generating unit, so that water enters the main heating boiler 12, and close the vacuum connection valve 11. Turn on the heating control power of the main heating boiler, and at the same time turn on the ...

Embodiment 2

[0087] For steam condensation heat transfer experiments containing air, the technical solution is: first close the vacuum connection valve 11 between the main heating boiler 12 of the steam generating unit and the auxiliary heating boiler 10, open the vacuum pipe joint 5 on the condensation pressure drop unit, Turn on the vacuum pump 7 to vacuumize the system. After vacuuming to the preset vacuum degree, add deionized water into the auxiliary heating boiler 10 of the steam generating unit, heat and boil for 30 minutes, and lower the water temperature to the preset steam temperature value. After vacuuming to the limit of the vacuum pump, close the vacuum pipe joint 5, open the vacuum connection valve 11 between the main heating boiler 12 and the auxiliary heating boiler 10 of the steam generating unit, so that water enters the main heating boiler 12, and close the vacuum connection valve 11. Turn on the heating control power of the main heating boiler, and at the same time turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com