Trace hydrotalcite titration measurement method

A technology of aluminum magnesium carbonate and measurement method, which is applied in the direction of chemical analysis by titration method, measurement device, chemical method analysis, etc., and can solve problems such as complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

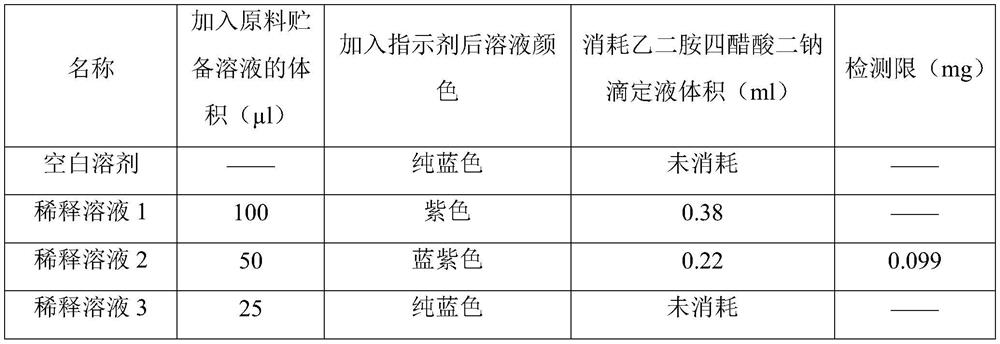

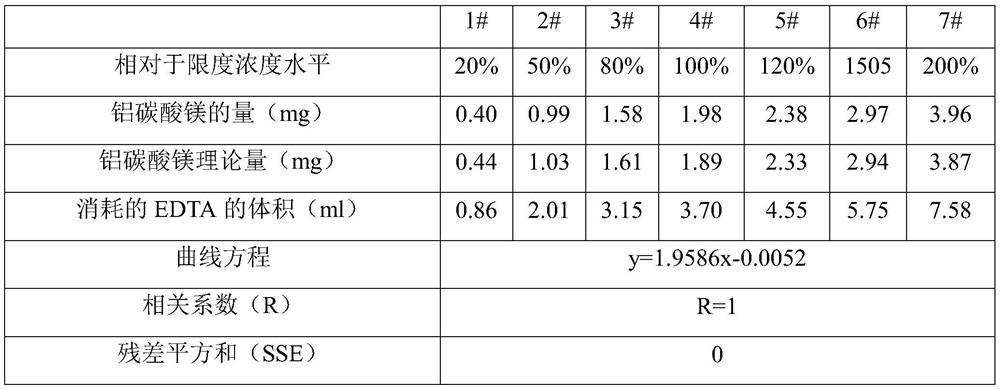

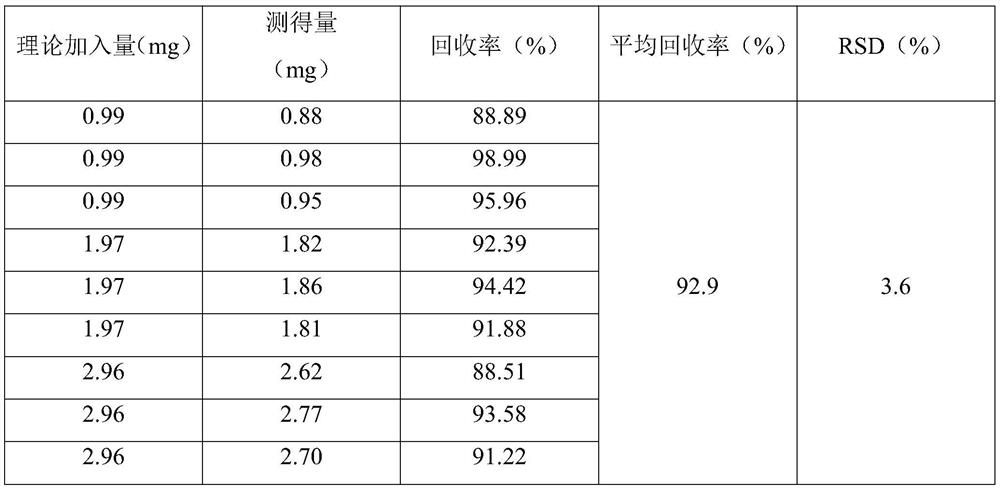

[0010] method validation

[0011] The detection limit, accuracy, intermediate precision, linearity and range were mainly investigated.

[0012] 1. Detection limit

[0013] 1.1 Solution preparation

[0014] 1) Standard stock solution: take about 100 mg of aluminum magnesium carbonate raw material, accurately weigh it, put it in a 50 ml measuring bottle, add 1 ml of 7mol / L hydrochloric acid solution to dissolve, add purified water to the mark and shake well, and use it as a standard stock solution.

[0015] 2) Dilute solution 1: Take 100 μl of the standard stock solution, put it in a 500ml Erlenmeyer flask, add 30ml of water, shake well, and get ready.

[0016] 3) Dilute solution 2: Take 50 μl of the standard stock solution, put it in a 500ml Erlenmeyer flask, add 30ml of water, shake well, and obtain.

[0017] 4) Dilute solution 3: Take 25 μl of the standard stock solution, put it in a 500ml Erlenmeyer flask, add 30ml of water, shake well, and obtain.

[0018] 5) Blank solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com