A method for the production of a room-temperature acidic beverage containing sporic bacillus coagulans

一种凝结芽孢杆菌、酸性饮料的技术,应用在生产包含芽孢状凝结芽孢杆菌的室温酸性饮料领域,能够解决未进行等问题,达到维持稳定性、消除有害细菌、延长保质期的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

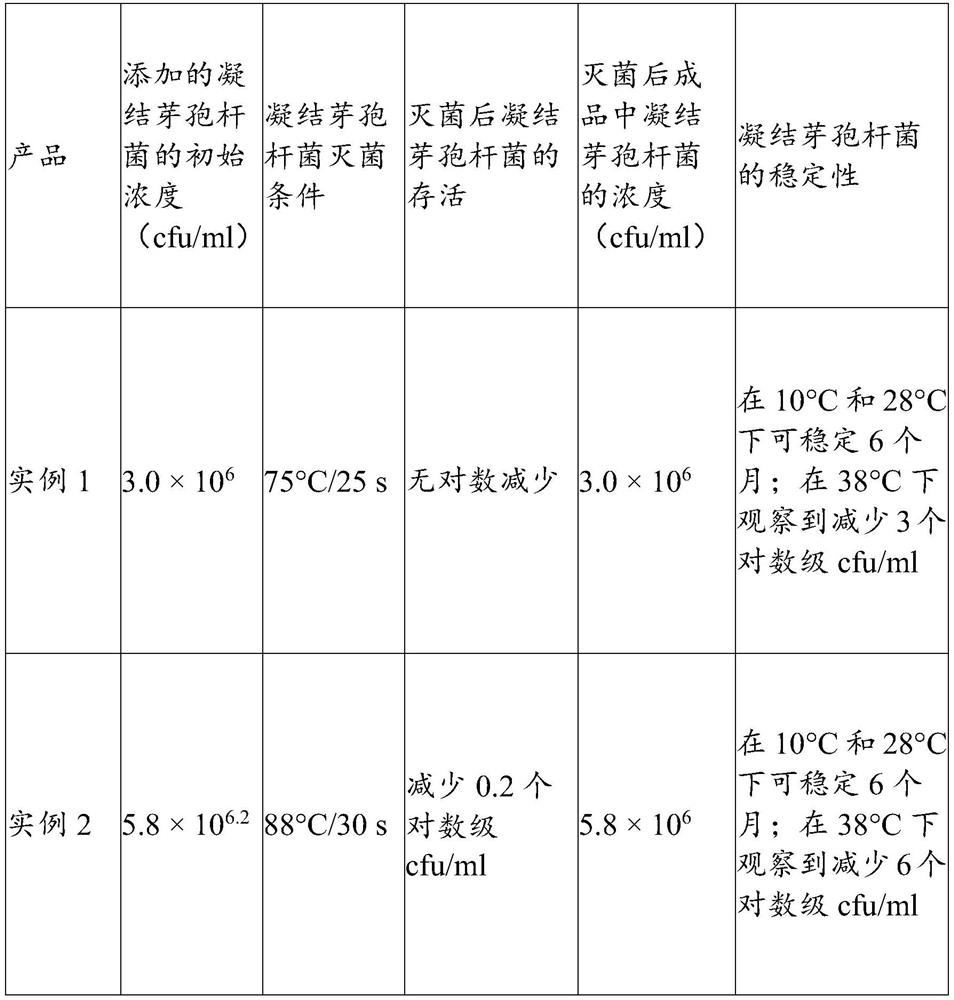

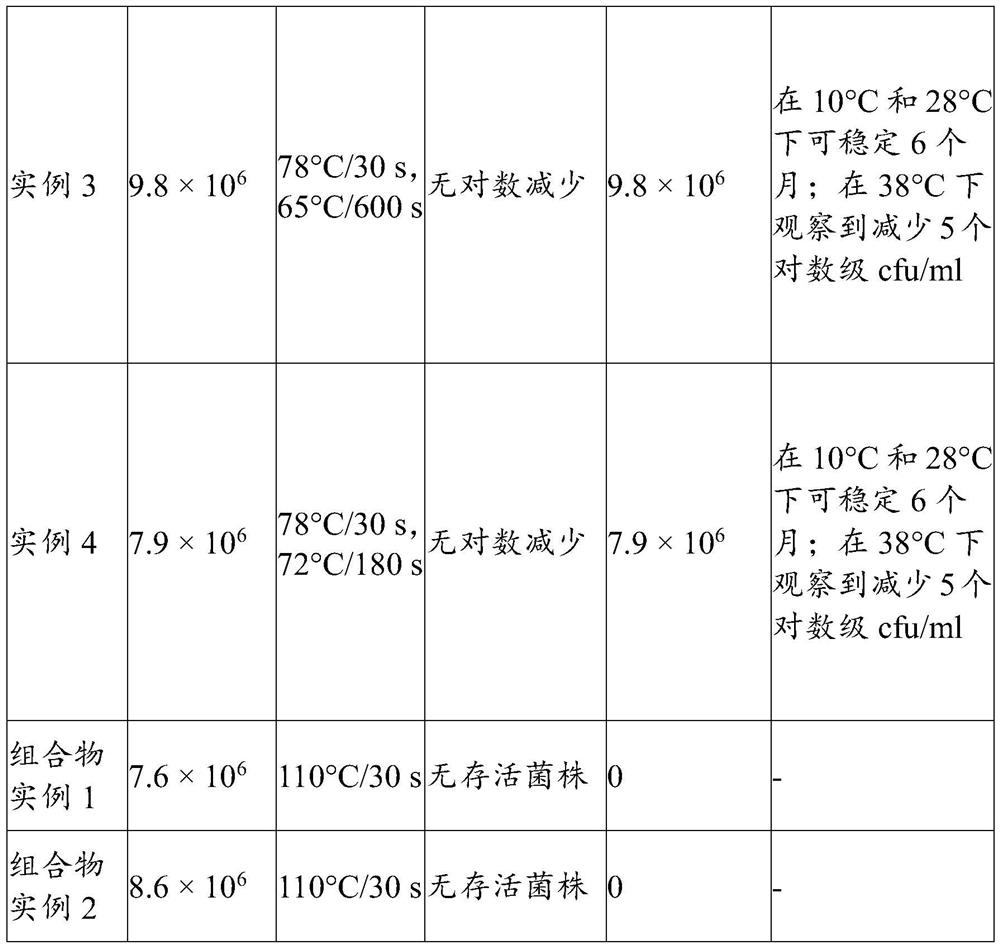

example 1

[0032] 1. Raw material

[0033] Long-life yogurt (contains 2.7% protein), Bacillus coagulans, sterile water.

[0034] 2. Method

[0035] 2.1. Sterilize the environmentally-friendly long-life yogurt at 75°C for 25s.

[0036] 2.2. Disperse Bacillus coagulans in sterile water (the ratio of bacteria raw material to water is 1:5), and pasteurize the solution at 75° C. for 25 s.

[0037] 2.3. The aseptic yogurt obtained in step 2.1 and the bacillus coagulans solution obtained in step 2.2 are mixed online, and aseptically sent into canned packaging to obtain a finished yogurt containing bacillus coagulans.

[0038] 3. Results

[0039] Since the long shelf-life yogurt itself contains only a small amount of microorganisms, it can be completely sterilized at 75°C for 25s. The long-life yogurt containing Bacillus coagulans produced by the methods described herein exhibits a pleasing texture and mouthfeel. Testing showed no log reduction in Bacillus coagulans counts for the final pro...

example 2

[0041] 1. Raw material

[0042] Yogurt drink containing yogurt base (2.0% protein), Bacillus coagulans, sterile water.

[0043] 2. Method

[0044] 2.1. Prepare a yogurt drink and sterilize it at a temperature of 110°C for 30s.

[0045] 2.2. Disperse Bacillus coagulans in sterile water (the ratio of bacterial raw material to water is 1:5), and pasteurize at 88°C for 30s.

[0046] 2.3. At a temperature of 88° C., the solution obtained in the previous two steps was hot-filled to obtain the final yoghurt drink product.

[0047] 3. Results

[0048] Yogurt drinks containing Bacillus coagulans showed good texture and mouthfeel. Testing showed a 0.2 log reduction in Bacillus coagulans in the final product.

example 3

[0050] 1. Raw material

[0051] Flavored yogurt drink (with 1.0% protein), Bacillus coagulans, sterile water.

[0052] 2. Method

[0053] 2.1. Prepare the flavored yogurt drink and sterilize it at 110° C. for 30 seconds.

[0054] 2.2. Disperse Bacillus coagulans in sterile water (the ratio of bacteria raw material to water is 1:5), and pasteurize at 78°C for 30s.

[0055] 2.3. Hot fill the solution obtained in the previous two steps at a temperature of 78°C.

[0056] 2.4. At a temperature of 65° C., pasteurize in a secondary container for 600 seconds to obtain a flavored yogurt drink.

[0057] 3. Results

[0058] Flavored yogurt drinks containing Bacillus coagulans showed good texture and mouthfeel. Testing showed no log reduction of Bacillus coagulans in the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com