Lubricating ring and clutch module comprising such a lubricating ring

A technology for lubricating rings and clutches, which is applied in clutches, friction clutches, fluid-driven clutches, etc., and can solve the problems of clutch module assembly difficulties, technical and operational difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In the following description and claims, for ease of understanding, the following terms will be used without limitation:

[0056] - "front" or "rear" in a direction defined relative to the axial orientation determined by the axis of rotation O of the clutch module or assembly, "rear" meaning the part located on the right in the figure, for example on the side of the gearbox, and "front" means the left part of the figure, such as the side of the internal combustion engine; and

[0057] - "inner / inner" or "outer / external" with respect to the axis of rotation O and in a radial orientation orthogonal to the axial orientation, "inner" meaning the part near the axis of rotation O and "outer" meaning the The part away from the axis of rotation O.

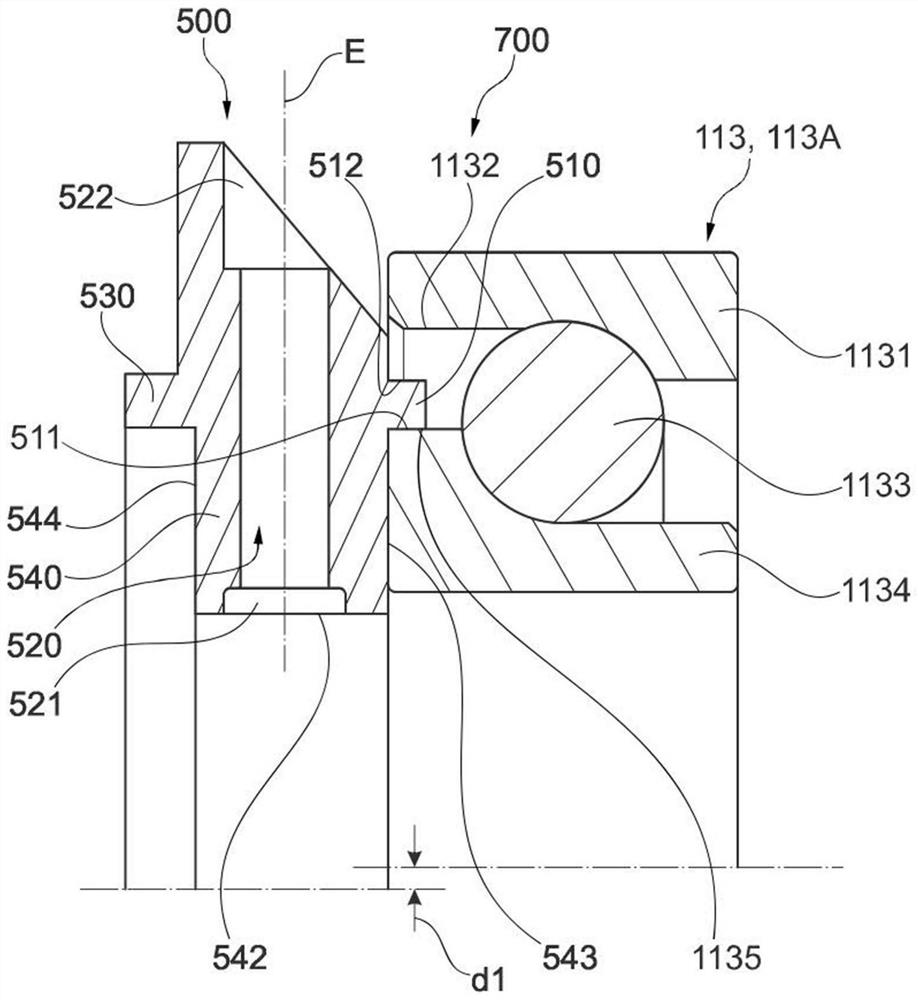

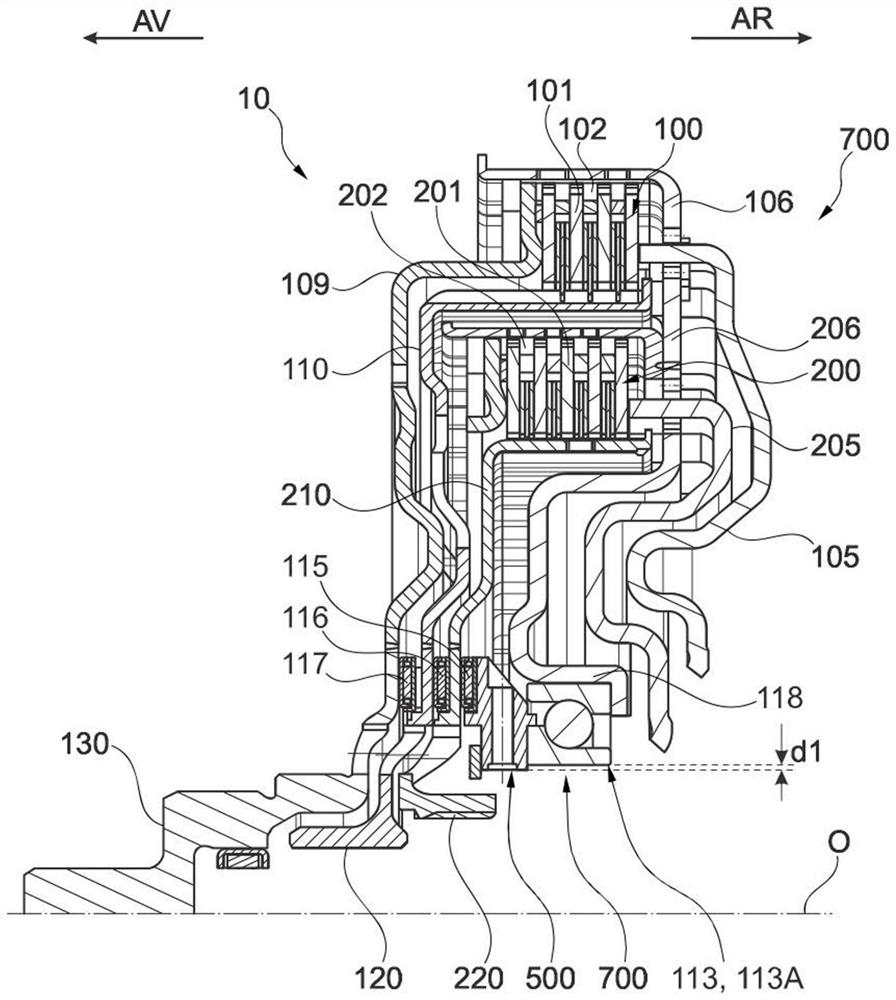

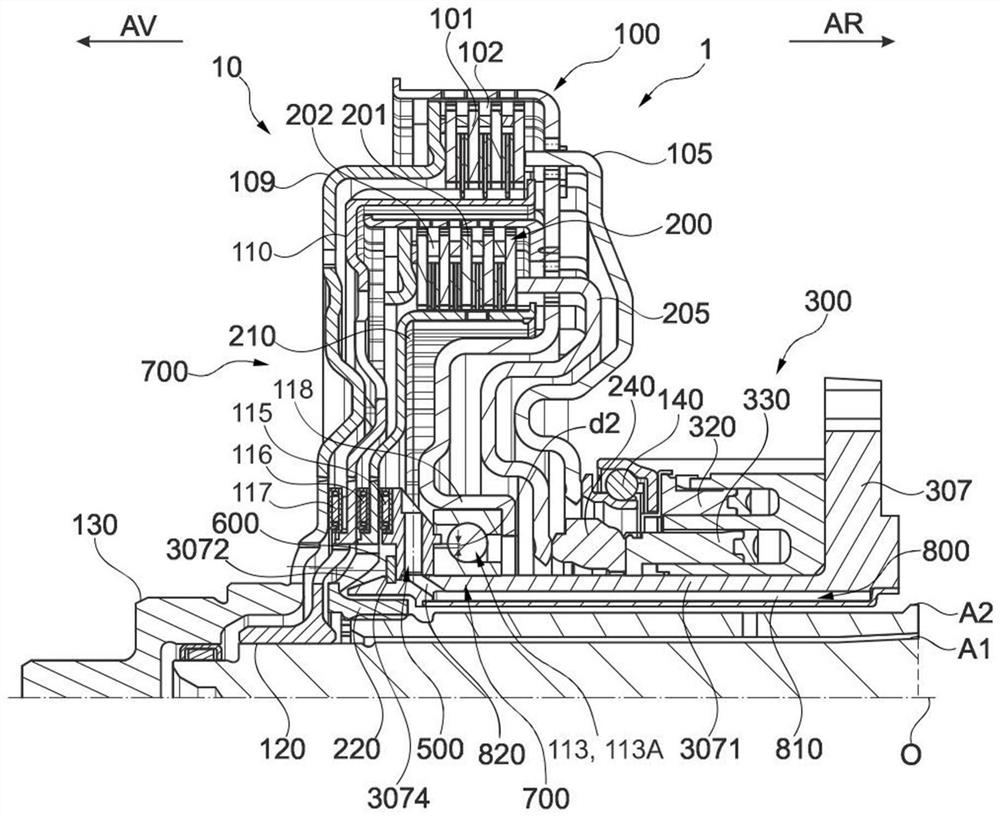

[0058] figure 1 An embodiment of an assembly 700 according to the second aspect of the invention is shown, comprising a lubricating ring 500 according to the first aspect of the invention and a release bearing 113A.

[0059] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com