Sheepskin jelly production process based on wool removal, removal of fat in sheepskin and mutton odor treatment

A production process and sheep mutton flavor technology, which can be used in food ingredients as taste modifiers, food ingredients as taste modifiers, food science and other directions, can solve the problems of fishy mutton smell, difficult to process, and sheepskin jelly is not delicious. To achieve the effect of thorough removal, rich taste of finished products, and improved quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

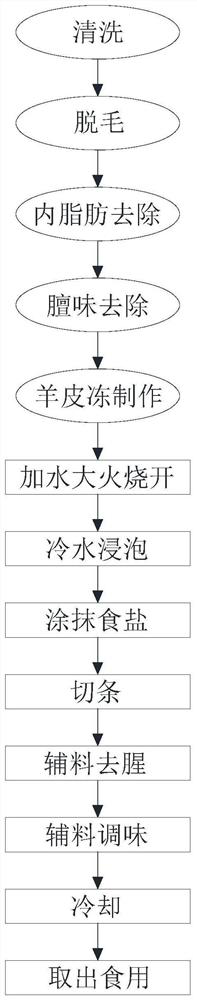

[0021] Example: such as figure 1 As shown, a sheepskin jelly production process based on wool removal, sheepskin inner fat removal and sheepskin odor treatment includes the following steps:

[0022] S1 Cleaning: Take multiple pieces of fat sheepskin in the wool belt, wash off the blood and stains on the sheepskin with warm water, and let it stand for later use.

[0023] S2 hair removal: Pour boiling water into a stainless steel container, immerse the pretreated sheepskin in the boiling water and take it out immediately, pull out the wool after taking it out, and then immerse the sheepskin in the boiling water, repeat two to four times. After the boiling water touches the sheepskin, the hair follicles expand, making it easier to pull out the hair.

[0024] S3 internal fat removal: inject ammonium carbonate solution into the sprayer, spray the sodium carbonate solution evenly on the side of the sheep belt with internal fat through the sprayer, after standing for a period of tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com