Preparation process of moisture-removing agent for transformer substation cabinet

A preparation process and substation technology, applied in the substation/distribution device casing, separation method, chemical instrument and method, etc., to achieve the effect of solving damage, facilitating evaporation, and good moisture absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

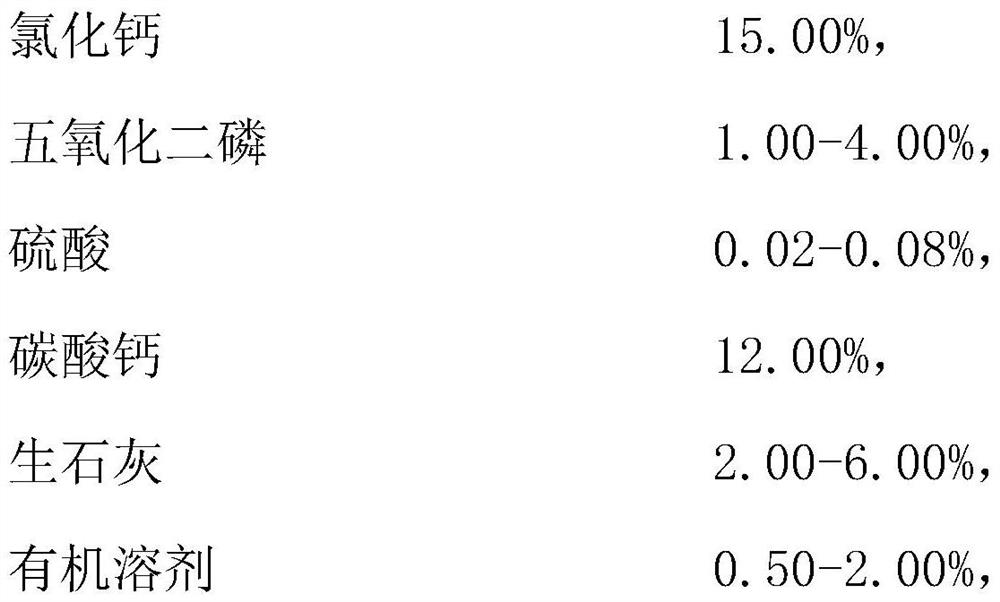

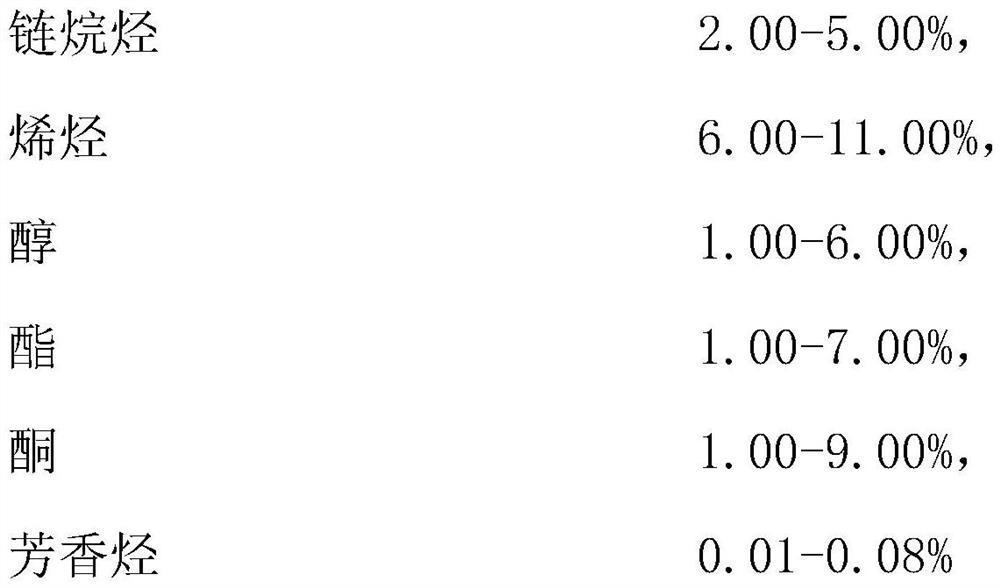

[0025] The weight ratio of each component is:

[0026]

[0027] The remainder is added with water solvent.

[0028] a. Accurately weigh 15% of calcium chloride and 1.00% of phosphorus pentoxide, dissolve and mix them evenly with an appropriate amount of water solvent, then accurately weigh 0.02% of sulfuric acid and add them, and add calcium chloride and pentoxide to the sulfuric acid Diphosphorus and sulfuric acid are mixed and stirred uniformly to prepare solution A, then accurately weigh 12.00% of calcium carbonate and 2.00% of quicklime, dissolve and mix with an appropriate amount of water solvent, and then accurately weigh 0.50% of the organic solvent and add it to make The organic solvent can be fully mixed with calcium carbonate and quicklime to prepare solution B, and finally the prepared solution A and solution B are mixed and stirred evenly;

[0029] b. Import the mixed solution prepared in step a above into a homogenizer, and set a pressure of 20MPa to homogeniz...

Embodiment 2

[0033] The weight ratio of each component is:

[0034]

[0035] The remainder is added with water solvent.

[0036] a. Accurately weigh 15% of calcium chloride and 2.00% of phosphorus pentoxide, dissolve and mix them evenly with an appropriate amount of water solvent, then accurately weigh 0.04% of sulfuric acid and add them, and add calcium chloride and pentoxide to sulfuric acid Diphosphorus and sulfuric acid are mixed and stirred uniformly to prepare solution A, and then accurately weighed 12.00% of calcium carbonate and 3.50% of quicklime, dissolved in an appropriate amount of water solvent, mixed and stirred evenly, and then accurately weighed 1.00% of organic solvent and added thereto, making The organic solvent can be fully mixed with calcium carbonate and quicklime to prepare solution B, and finally the prepared solution A and solution B are mixed and stirred evenly;

[0037] b. Import the mixed solution prepared in step a above into a homogenizer, and set a pressu...

Embodiment 3

[0041] The weight ratio of each component is:

[0042]

[0043] The remainder is added with water solvent.

[0044] a. Accurately weigh 15.00% of calcium chloride and 3.00% of phosphorus pentoxide, dissolve and mix them evenly with an appropriate amount of water solvent, then accurately weigh 0.06% of sulfuric acid and add them, and add calcium chloride and pentoxide to sulfuric acid Diphosphorus and sulfuric acid are mixed and stirred uniformly to prepare solution A, and then accurately weighed 12.00% of calcium carbonate and 4.50% of unslaked lime, dissolved and mixed with an appropriate amount of water solvent, and then accurately weighed 1.50% of the organic solvent and added thereto, making The organic solvent can be fully mixed with calcium carbonate and quicklime to prepare solution B, and finally the prepared solution A and solution B are mixed and stirred evenly;

[0045] b. Import the mixed solution prepared in step a above into a homogenizer, and set a pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com