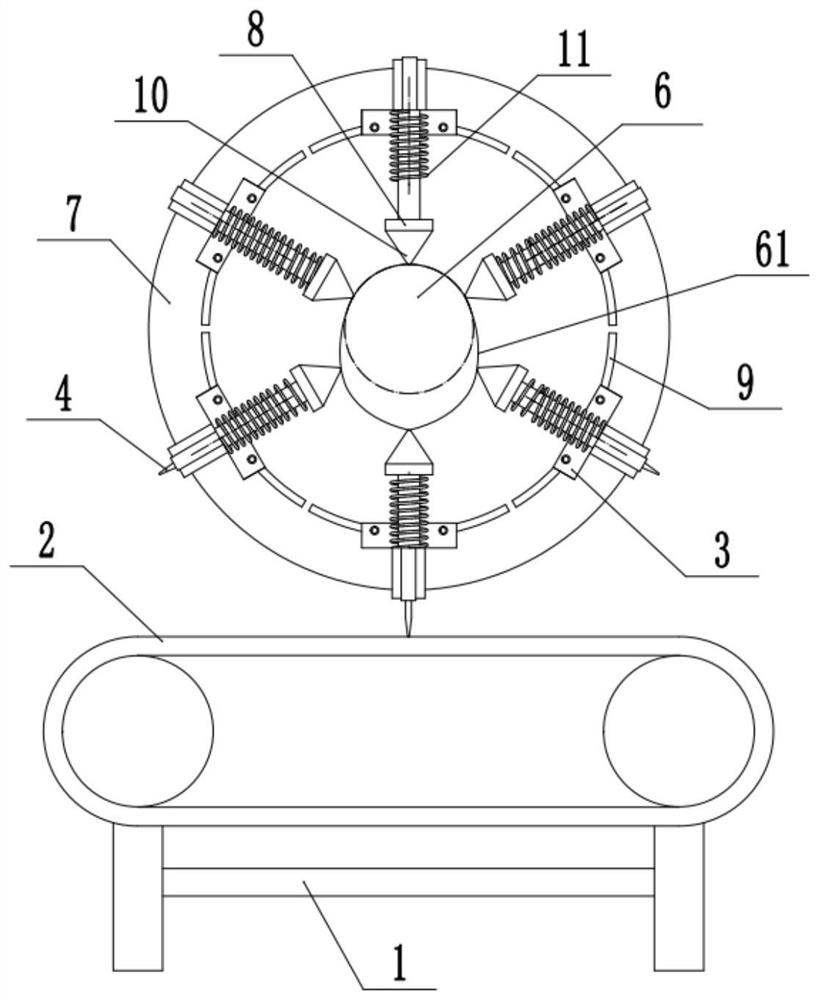

Agricultural product processing machine

A technology for agricultural products and processing machines, applied in metal processing and other directions, can solve problems such as low efficiency and easy occurrence of safety accidents, and achieve the effects of good processing quality, wide application range and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

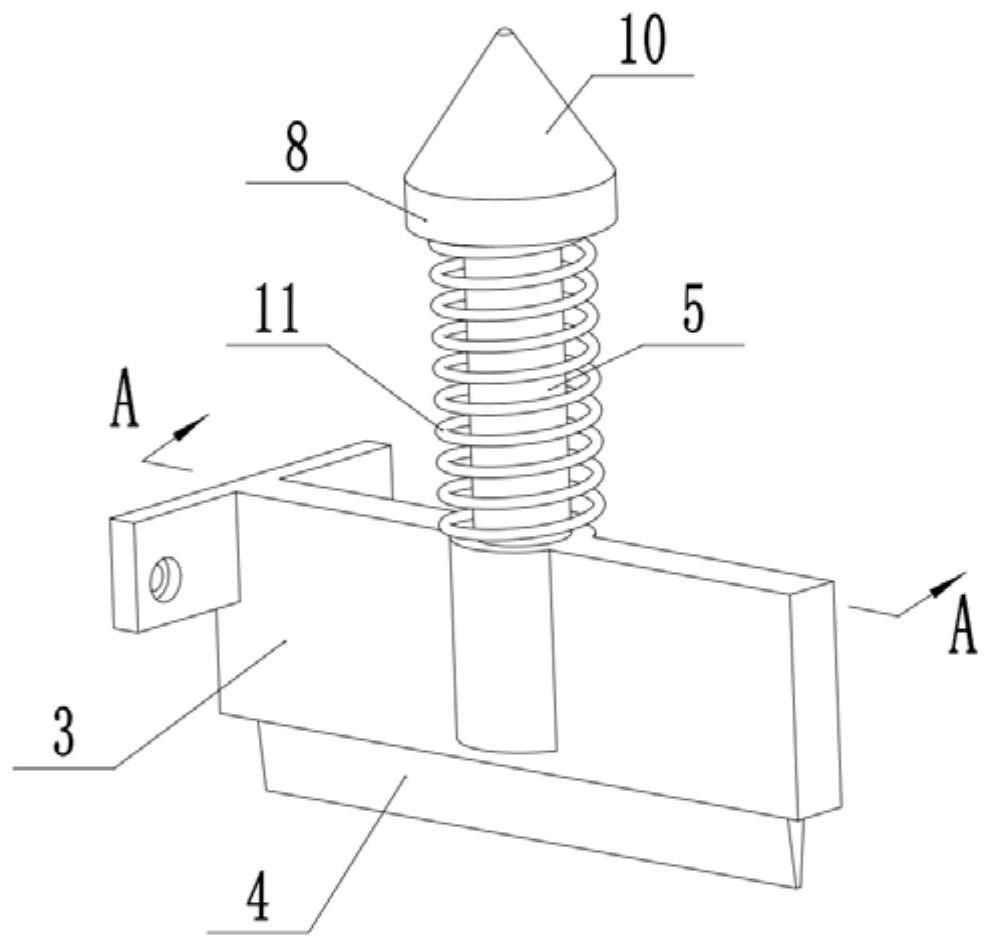

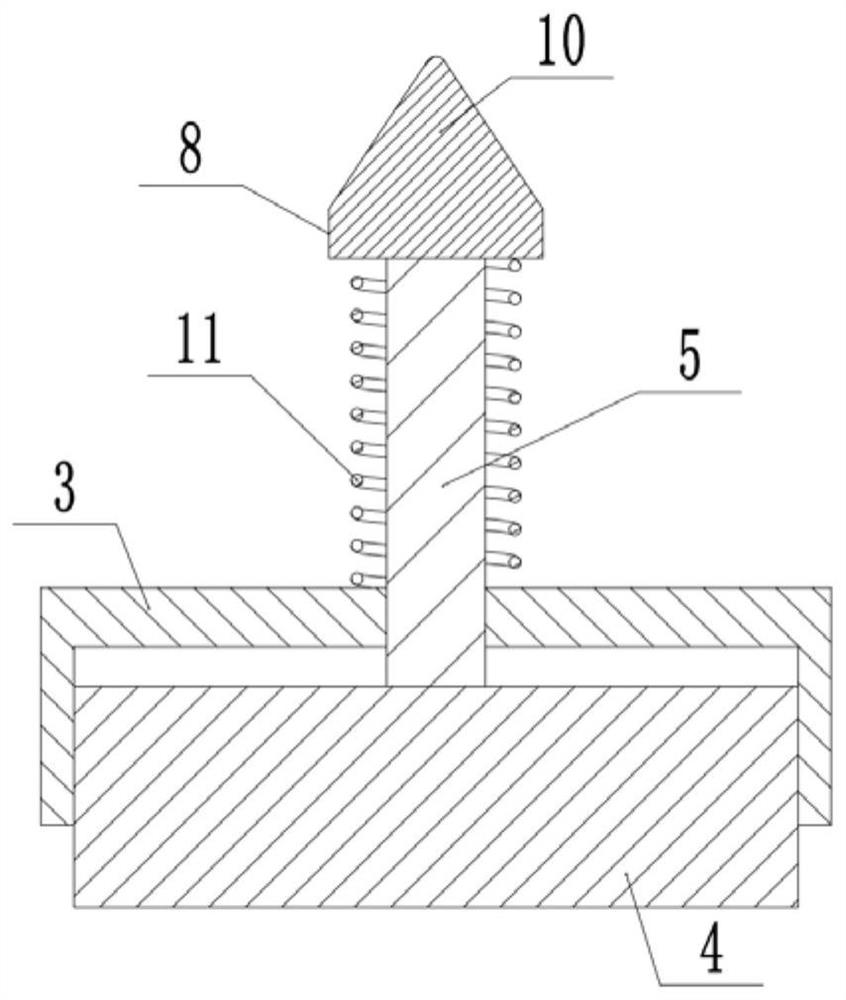

Examples

Embodiment 2

[0043] The difference between embodiment two and embodiment one is: as Figure 4 and Figure 5 As shown, in this embodiment, the adjusting block 8 is fixedly connected with a sleeve 12 by screws, and the connecting rod 5 is slidably connected in the sleeve 12. In order to prevent the connecting rod 5 from slipping out of the sleeve 12, the sleeve 12 The end away from the adjustment block 8 is provided with a stepped hole, and the diameter of the stepped hole is reduced near the end of the sleeve 12 away from the adjustment block 8, and the end of the connecting rod 5 located in the sleeve 12 is provided with a protrusion, through the stepped hole and the protrusion The cooperation of the connecting rod 5 has been realized to prevent the connecting rod 5 from slipping out of the sleeve 12; at the same time, a second elastic support is placed in the sleeve 12, and the second elastic support includes the first connecting rod 5 and the adjusting block 8 at both ends. The second s...

Embodiment 3

[0045] The difference between embodiment three and embodiment two is: as Figure 6 and Figure 7 As shown, two scrapers 14 are connected through T-shaped slots on the opposite side walls of the notches on the cutter cover 3 , which are adjacent to the placement slot. , a third elastic support is provided in the slot, and the third elastic support includes a plurality of third springs 15 (in this embodiment, each scraper 14 is correspondingly provided with three third springs 15), and the elastic force of the third springs 15 Under the action, the two scrapers 14 tend to approach each other. When the cutter 4 partly slides out of the cutter cover 3, the scraper 14 is against the side wall of the cutter 4, so that when the cutter 4 slides back into the slot, , the scraper 14 scrapes the two side walls of the cutter 4 to prevent the processed agricultural products (especially sliced agricultural products) from adhering to the side walls of the cutter 4, so as to prevent the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com