Online reduction method and device for additive composite manufacturing stress based on symmetric high-frequency vibration

A high-frequency vibration and vibration device technology, applied in the field of additive composite manufacturing, can solve problems such as affecting manufacturing efficiency and increasing manufacturing costs, and achieve the effects of improving stress reduction effect, increasing energy input, and increasing amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

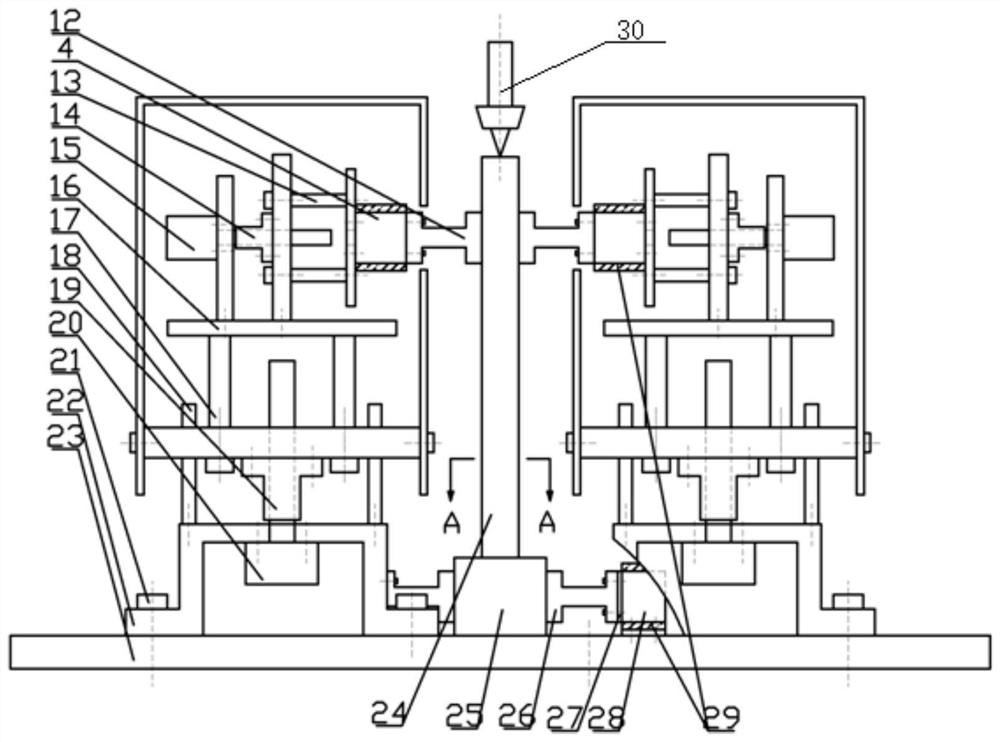

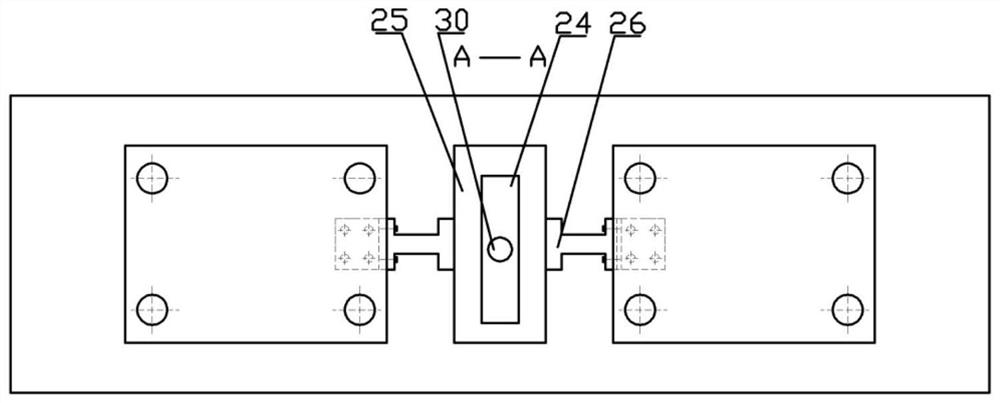

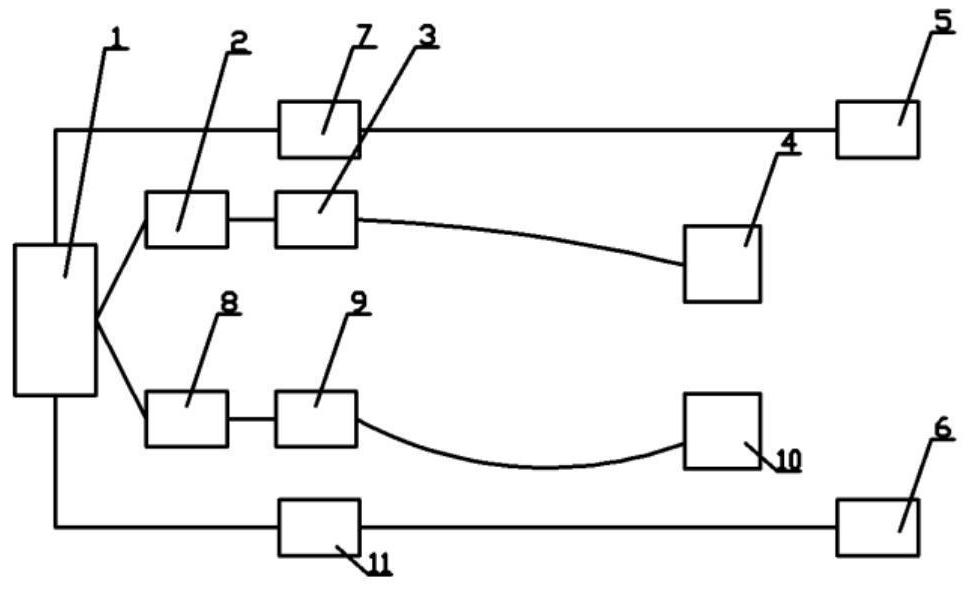

[0033] In order to further illustrate the high-frequency vibration additive manufacturing workpiece stress online relief device, the description is as follows in conjunction with the accompanying drawings.

[0034] Such as figure 1 , 2 A workpiece 24 of an additively manufactured workpiece is shown disposed on a base body 25 . The base body 25 is arranged on the workbench 23, and on its left and right sides, a lower end vibration amplifier 26 is provided, and the lower end vibration amplifier 26 is used for clamping and fixing the workpiece. The other end of the lower vibrating amplifier 26 is provided with a lower electromagnetic exciter 28 , which generates an amplitude and acts on the workpiece 24 through the amplification of the lower vibrating amplifier 26 . The base body 25 is adjusted and clamped by changing the thickness of the adjusting sheet 27 . Adjustment brackets 22 are arranged on both sides of the lower high-frequency vibration device, and the adjustment brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com