Acetate fabric dyeing carrier and preparation method thereof

A kind of acetate and fabric technology, applied in the direction of dyeing, textile and paper making, etc., can solve the problems of strength drop, unstable size, easy fading, etc., to achieve the effect of small health impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

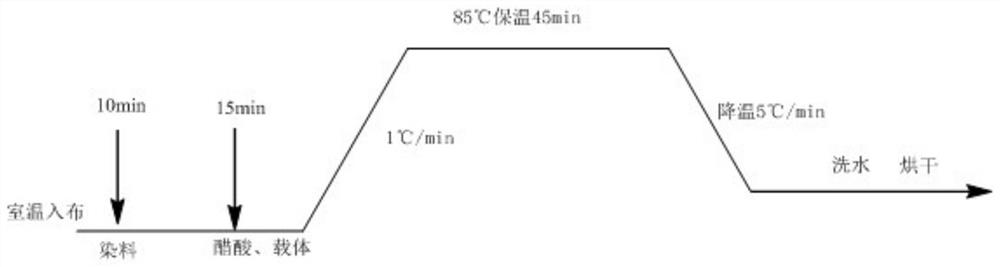

Method used

Image

Examples

Embodiment 1

[0021] The present embodiment provides a kind of preparation method of acetate fabric dyeing carrier, comprises the following steps:

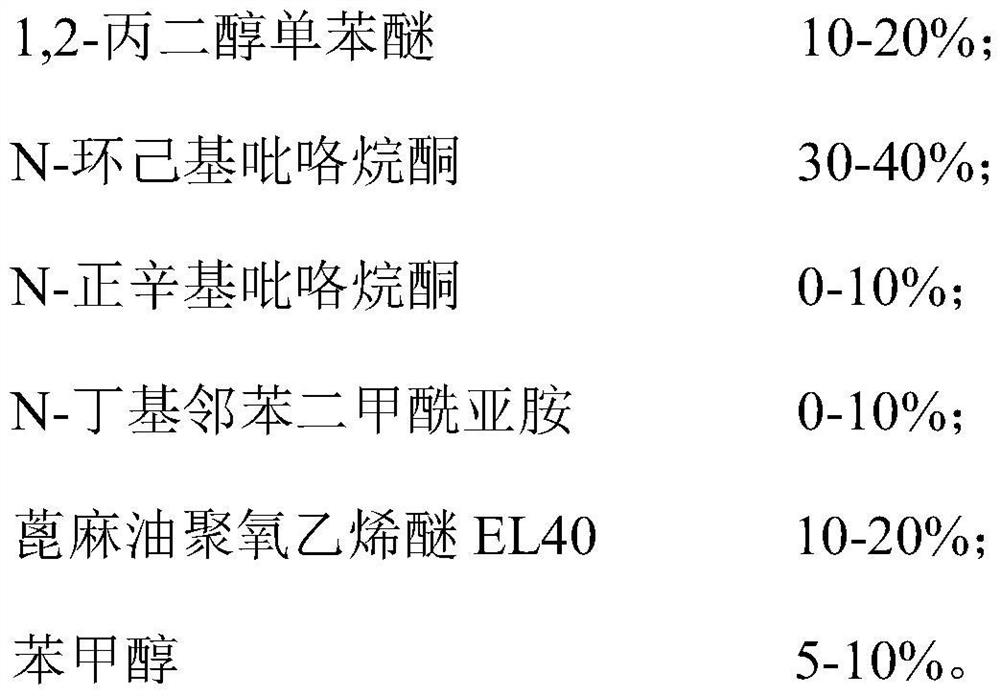

[0022] S1), components

[0023]

[0024] S2), add 200g of 1,2-propylene glycol monophenyl ether, 350g of N-cyclohexylpyrrolidone, 50g of N-octylpyrrolidone, and 100g of N-butylphthalimide in a clean and dry 1000ml reaction bottle, Castor oil polyoxyethylene ether EL40 200g, benzyl alcohol 100g, stirred for 40min, and mixed evenly to prepare the dyeing carrier of acetate fiber fabric, which was in the form of transparent liquid.

Embodiment 2

[0026] The present embodiment provides a kind of preparation method of acetate fabric dyeing carrier, comprises the following steps:

[0027] S1), components

[0028]

[0029] S2), add 1,2-propanediol monophenyl ether 100g, N-cyclohexylpyrrolidone 300g, N-octylpyrrolidone 40g, N-butylphthalimide 50g, Castor oil polyoxyethylene ether EL40 100g, benzyl alcohol 50g, stirred for 45min, and mixed evenly to prepare acetate fiber fabric dyeing carrier, which was in the form of transparent liquid.

Embodiment 3

[0031] The present embodiment provides a kind of preparation method of acetate fabric dyeing carrier, comprises the following steps:

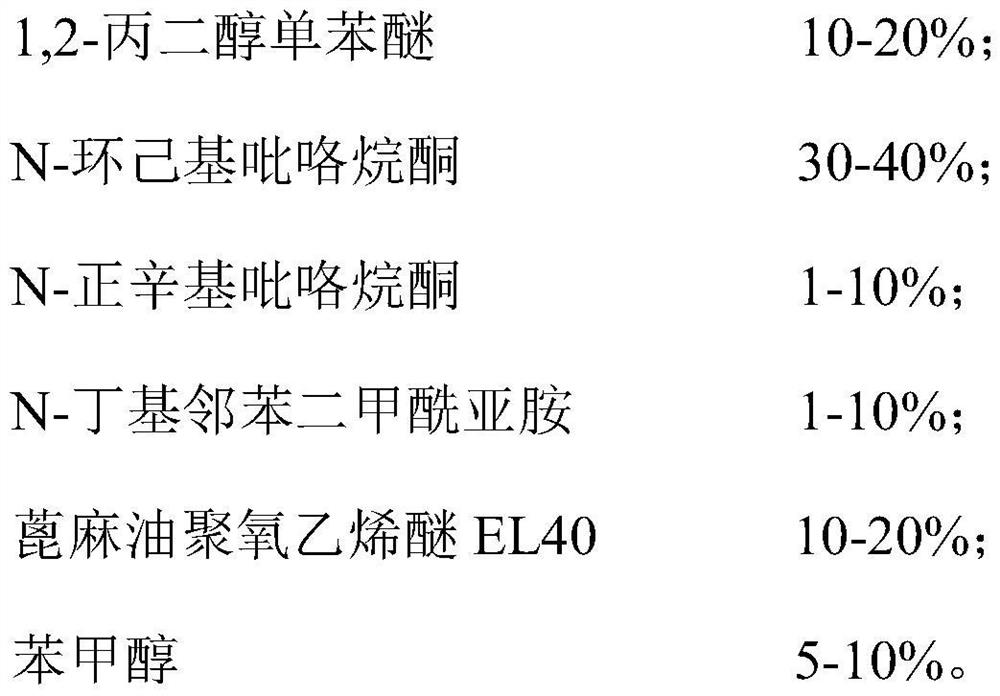

[0032] S1), components

[0033]

[0034]

[0035] S2), add 1,2-propanediol monophenyl ether 150g, N-cyclohexylpyrrolidone 400g, N-octylpyrrolidone 100g, N-butylphthalimide 100g, Castor oil polyoxyethylene ether EL40150g, benzyl alcohol 70g, stirred for 25min, and mixed uniformly to prepare acetate fabric dyeing carrier, which was in the form of transparent liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com