Method for assembling H-shaped steel combined special-shaped column portal rigid frame structure

A technology of portal frame and assembly method, which is applied in the direction of building structure, construction, and building material processing, etc., can solve the problems of limited section height of split T-shaped steel, high price of split T-shaped steel, and shortage of supply, etc., to achieve The effect of rich cross-section combination forms, solving the problem of material waste, and convenient procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

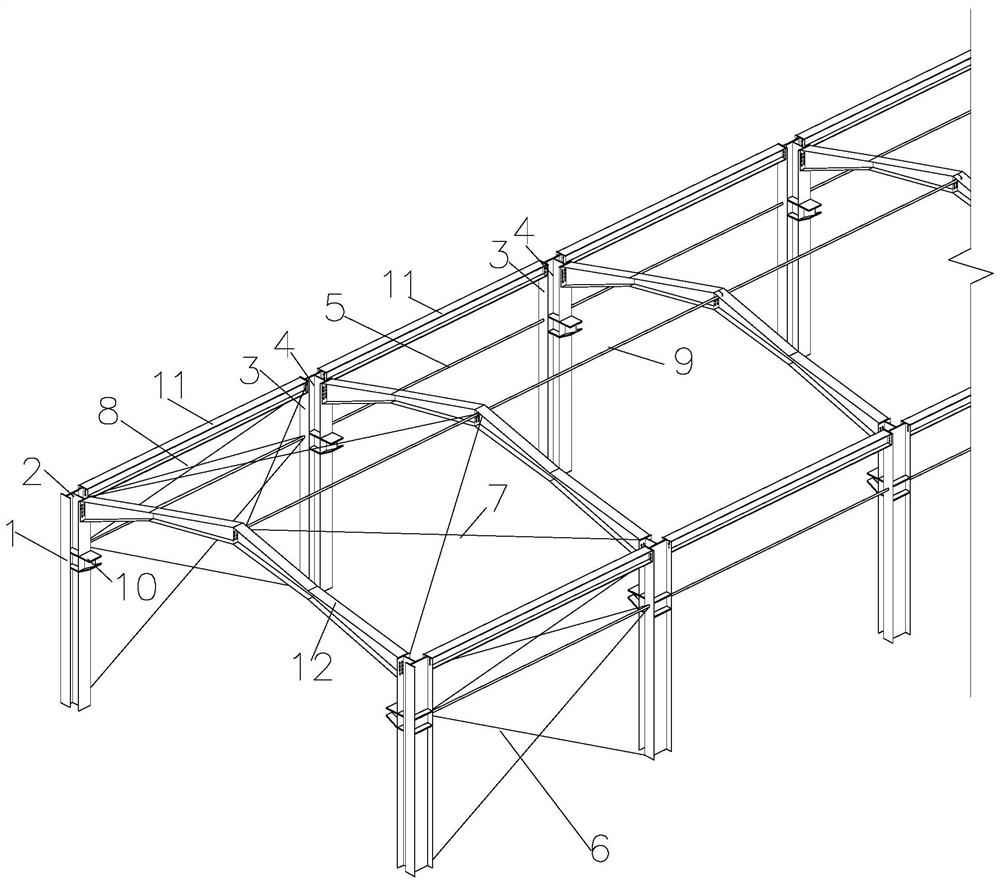

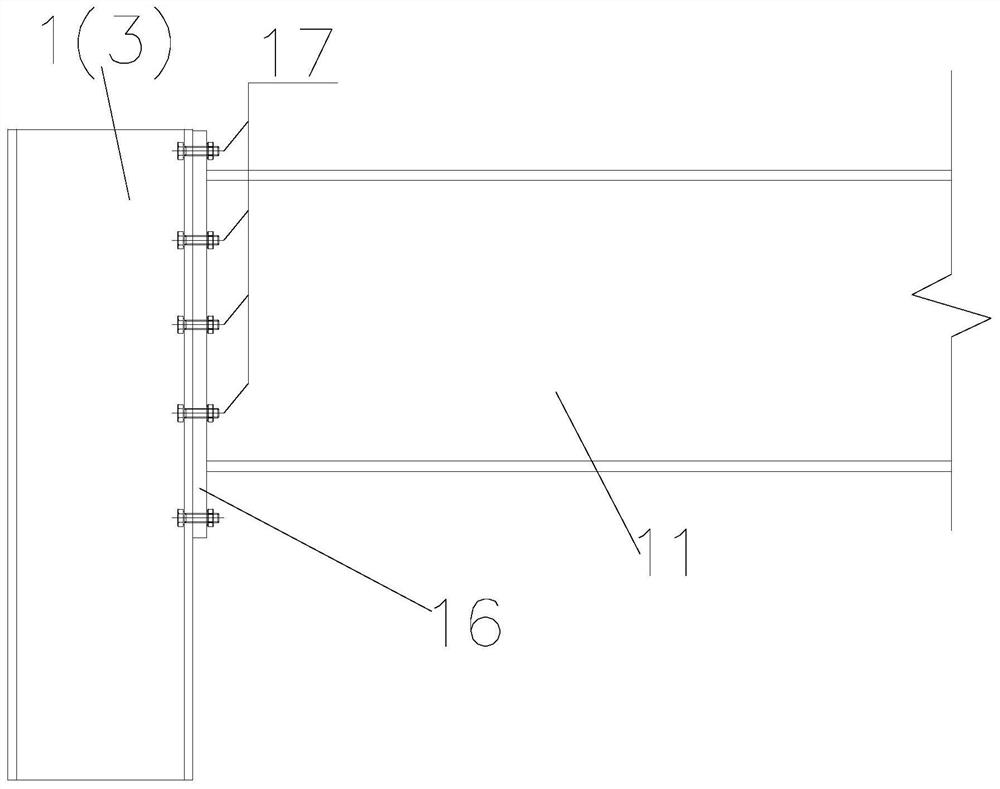

[0046] Such as Figure 1 to Figure 3 , Figure 7 As shown, a kind of H-shaped steel combined special-shaped column portal frame structure assembly method of the present invention comprises the following steps:

[0047] Step 1, prefabrication preparation: Prepare the H-shaped steel required for connecting the longitudinal steel beams 11 of two adjacent special-shaped column portal frames in the factory according to the design drawings;

[0048] The special-shaped column portal frame is an end portal frame located at the end of the frame structure or a median portal frame located in the middle of the frame structure;

[0049] According to the design drawings, prepare the H-shaped steel required for the L-shaped column of the end portal frame at the end of the frame structure and the T-shaped column of the middle portal frame located in the middle of the frame structure in the factory;

[0050] Among them, the L-shaped column includes the main H-shaped steel 1 of the L-shaped c...

Embodiment 2

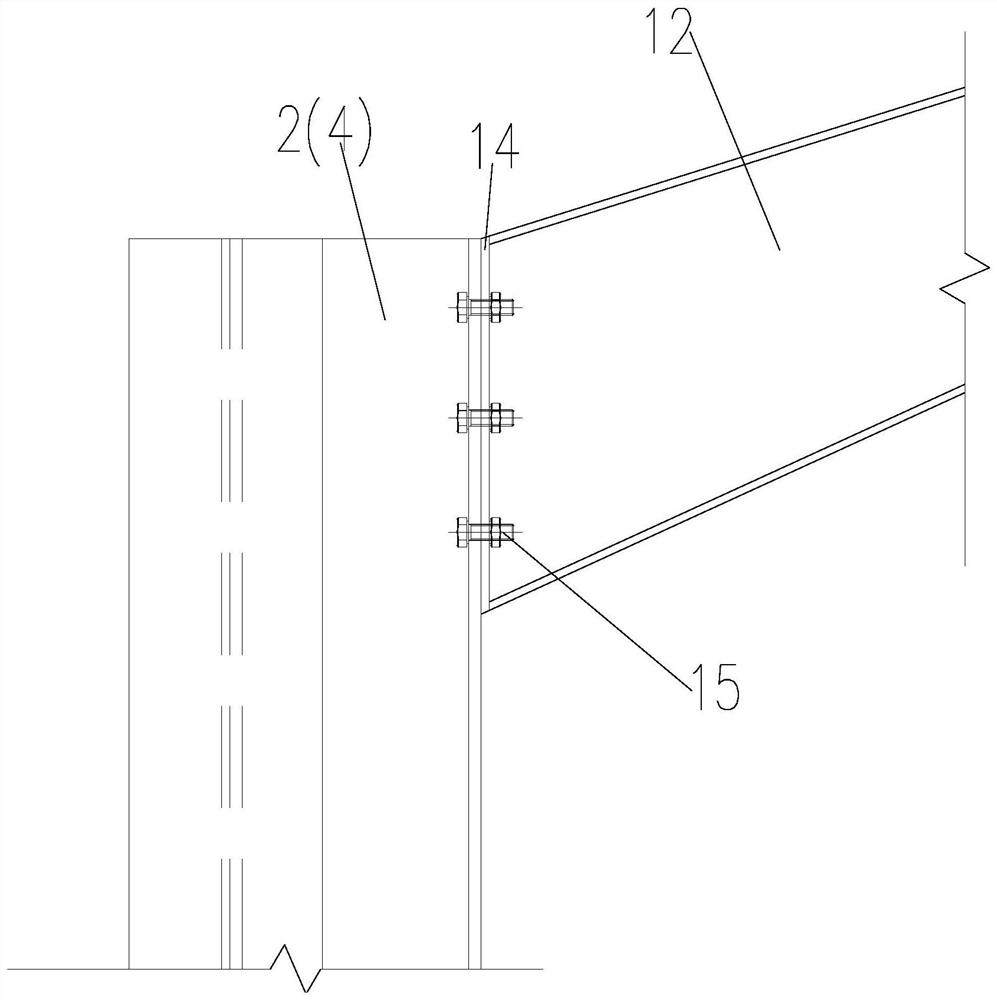

[0068] Such as Figure 4 to Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that in step 1, the web plate of the main H-shaped steel 1 of the L-shaped column and a flange plate assembly position of the auxiliary H-shaped steel 2 of the L-shaped column are punched in advance in the factory. A row of installation holes; two rows of installation holes are drilled at the assembly position of the web plate of the main H-shaped steel 3 of the T-shaped column and a flange plate of the auxiliary H-shaped steel 4 of the T-shaped column;

[0069] In step 2, during the assembly process of the end-position portal frame, a flange plate of the auxiliary H-shaped steel 2 of the L-shaped column is connected to the end of the web plate of the main H-shaped steel 1 of the L-shaped column through two rows of third high-strength bolts 13 position, forming an L-shaped column;

[0070] During the assembly process of the central portal frame, a flange plate of the auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com