Method for analyzing mixed alkali in hydrazine hydrate by hydrogen peroxide oxidation method

A hydrogen peroxide and mixed alkali technology, which is used in chemical method analysis, chemical analysis by titration, and material analysis, etc., can solve the problems of high final result of mixed alkali and affect the accuracy of experimental results, so as to make up for the vacancy in the measurement and improve the accuracy. The effect of stable, efficient and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

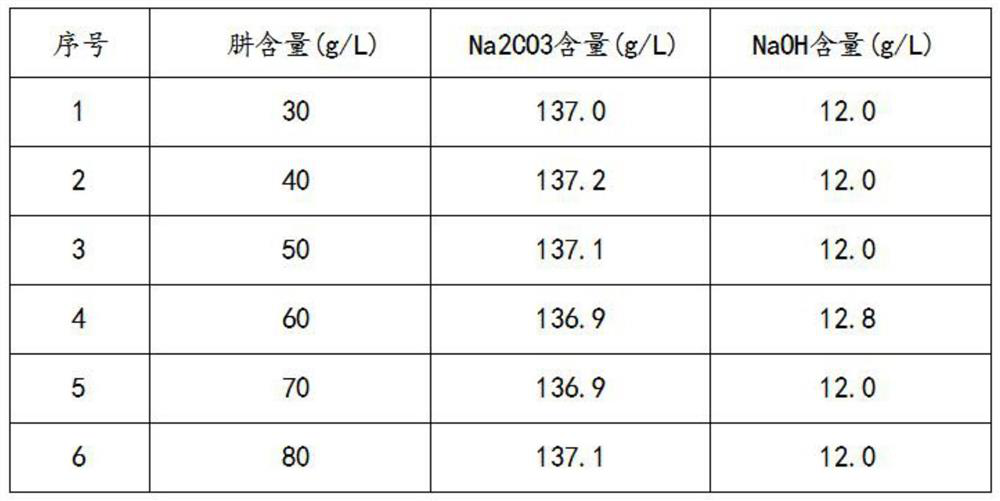

Embodiment 1

[0024] Embodiment one: a kind of hydrogen peroxide oxidation method analyzes the method for mixed alkali in hydrazine hydrate, comprises the following steps:

[0025] 1) Prepare samples with known hydrazine content and the content of each component of the mixed alkali, respectively prepare a mixed solution with a hydrazine concentration of 30 to 80 g / L, sodium carbonate of 137 g / L, and sodium hydroxide of 12 g / L;

[0026] ① Use a syringe to draw 36.5mL, 48.7mL, 60.9mL, 73.1mL, 85.3mL and 97.4mL of 821g / L hydrazine solution, and inject them into 1000mL volumetric flasks;

[0027] ②Add 137g of sodium carbonate and 12g of sodium hydroxide in turn to each volumetric flask;

[0028] ③Add water to dilute to the scale, so as to prepare Na2CO3 of 137g / L, NaOH of 12g / L and hydrazine concentrations of 30g / L, 40g / L, 50g / L, 60g / L, 70g / L and 80g / L A mixed solution of hydrazine;

[0029] 2) Take 25mL of the mixed solution in step 1) as the test sample, and add corresponding hydrogen perox...

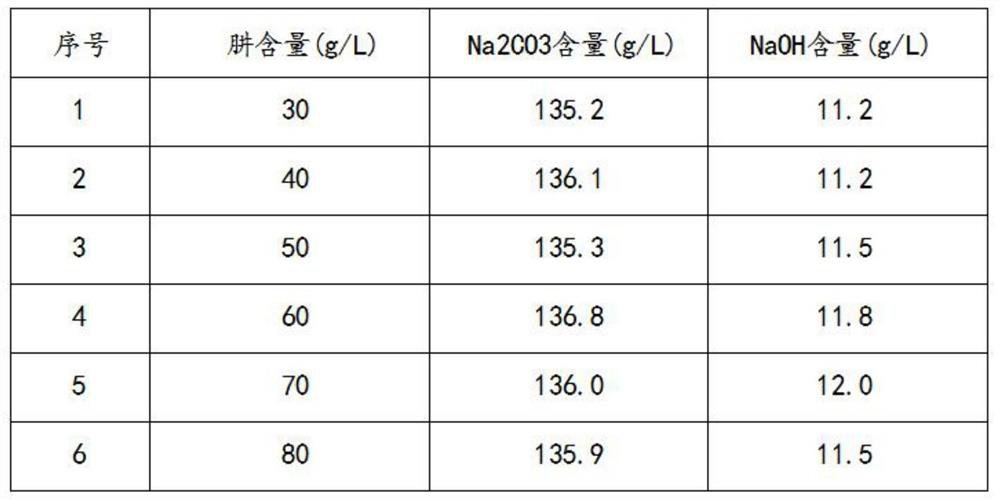

Embodiment 2

[0033] Embodiment two: a kind of hydrogen peroxide oxidation method analyzes the method for mixed alkali in hydrazine hydrate, comprises the following steps:

[0034] 1) Prepare samples with known hydrazine content and the content of each component of the mixed alkali, respectively prepare a mixed solution with a hydrazine concentration of 30 to 80 g / L, sodium carbonate of 137 g / L, and sodium hydroxide of 12 g / L;

[0035] ① Use a syringe to draw 36.5mL, 48.7mL, 60.9mL, 73.1mL, 85.3mL and 97.4mL of 821g / L hydrazine solution, and inject them into 1000mL volumetric flasks;

[0036] ②Add 137g of sodium carbonate and 12g of sodium hydroxide in turn to each volumetric flask;

[0037] ③Add water to dilute to the scale, so as to prepare Na2CO3 of 137g / L, NaOH of 12g / L and hydrazine concentrations of 30g / L, 40g / L, 50g / L, 60g / L, 70g / L and 80g / L A mixed solution of hydrazine;

[0038] 2) Take 25mL of the mixed solution in step 1) as the test sample, and add corresponding hydrogen perox...

Embodiment 3

[0042] Embodiment three: a kind of hydrogen peroxide oxidation method analyzes the method for mixed alkali in hydrazine hydrate, comprises the following steps:

[0043] 1) Prepare samples with known hydrazine content and the content of each component of the mixed alkali, respectively prepare a mixed solution with a hydrazine concentration of 30 to 80 g / L, sodium carbonate of 137 g / L, and sodium hydroxide of 12 g / L;

[0044] ① Use a syringe to draw 36.5mL, 48.7mL, 60.9mL, 73.1mL, 85.3mL and 97.4mL of 821g / L hydrazine solution, and inject them into 1000mL volumetric flasks;

[0045] ②Add 137g of sodium carbonate and 12g of sodium hydroxide in turn to each volumetric flask;

[0046] ③Add water to dilute to the scale, so as to prepare Na2CO3 of 137g / L, NaOH of 12g / L and hydrazine concentrations of 30g / L, 40g / L, 50g / L, 60g / L, 70g / L and 80g / L A mixed solution of hydrazine;

[0047] 2) Take 25mL of the mixed solution in step 1) as the test sample, and add corresponding hydrogen per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com