Novel preparation process of zinc stearate

A preparation process, the technology of zinc stearate, applied in the field of new zinc stearate preparation process, can solve the problem of excessive free acid, and achieve the effect of avoiding exceeding the standard and reducing the production of free acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

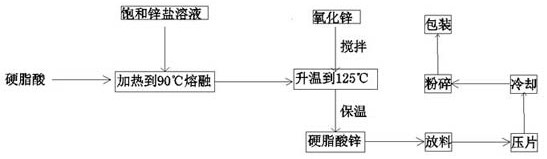

Image

Examples

Embodiment 1

[0026] A novel preparation process of zinc stearate, the specific preparation process is as follows:

[0027] S1: Add 1 ton of stearic acid into the reactor, heat up to 80°C, after the stearic acid is completely dissolved, add 8kg of saturated solution of zinc acetate into the reactor, and stir evenly;

[0028] S2: Raise the temperature of the reactor to 100°C again, add 148kg of zinc oxide, raise the temperature to 120°C again, keep warm at 120°C, and fully stir for 35 minutes;

[0029] S3: After the reaction is completed, the molten zinc stearate is discharged into the tablet press, and after the tablet is cooled, the flake material enters the jet mill for crushing. After the crushed product is collected by the pulse dust collector, it passes through the automatic packaging machine. Packing and storage; it is detected that the free acid content in zinc stearate is less than 0.15%.

Embodiment 2

[0031] A novel preparation process of zinc stearate, the specific preparation process is as follows:

[0032] S1: Add 1 ton of stearic acid into the reactor, heat up to 90°C, after the stearic acid is completely dissolved, add 3kg of zinc peroxide and 1kg of water into the reactor, and stir evenly;

[0033] S2: raise the temperature of the reactor to 110°C again, add 148kg of zinc oxide, raise the temperature to 125°C again, keep warm at 125°C, and fully stir for 40 minutes;

[0034] S3: After the reaction is completed, the molten zinc stearate is discharged into the tablet press, and after the tablet is cooled, the flake material enters the jet mill for crushing. After the crushed product is collected by the pulse dust collector, it passes through the automatic packaging machine. Packing and storage; it is detected that the free acid content in zinc stearate is less than 0.1%.

Embodiment 3

[0036] A novel preparation process of zinc stearate, the specific preparation process is as follows:

[0037] S1: Add 1 ton of stearic acid into the reactor, heat up to 90°C, after the stearic acid is completely dissolved, add 4.5 kg of saturated zinc chloride solution into the reactor, and stir evenly;

[0038] S2: raise the temperature of the reactor to 110°C again, add 148kg of zinc oxide, raise the temperature to 125°C again, keep warm at 125°C, and fully stir for 40 minutes;

[0039] S3: After the reaction is completed, the molten zinc stearate is discharged into the tablet press, and after the tablet is cooled, the flake material enters the jet mill for crushing. After the crushed product is collected by the pulse dust collector, it passes through the automatic packaging machine. wrap up and store. It was detected that the content of free acid in zinc stearate was less than 0.2%.

[0040] On the whole, the content of free acid in zinc stearate prepared by this scheme i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com