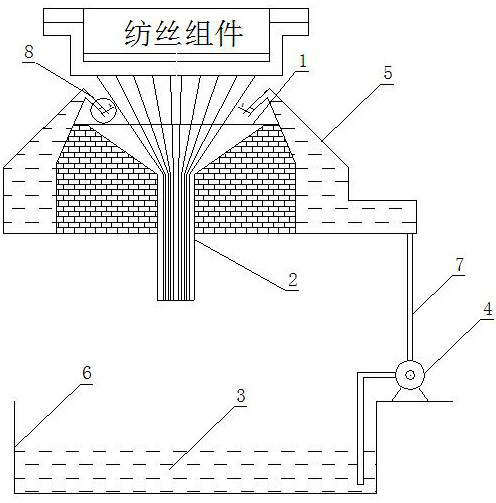

High-speed dry-wet spinning solidification device

A dry-wet spinning, high-speed technology, applied in the field of chemical fiber spinning, can solve the problems of uneven distribution of raw solution, small effective area, and high processing accuracy requirements, improve stability and space utilization efficiency, reduce broken yarns, Effect of improving spinning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

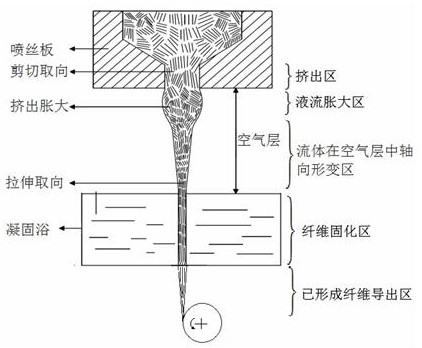

Embodiment 1

[0027] Dissolve poly-p-phenylene terephthalamide resin with a reduced viscosity of 6.3dl / g in 100% concentrated sulfuric acid at 85°C to prepare a 19.5wt% liquid crystal spinning solution, which is defoamed, filtered, and metered in sequence Finally, it is extruded from the spinneret with 0.063mm aperture, and then enters the solidification disk after passing through the air layer. The coagulation bath is 10% sulfuric acid solution, the temperature is 5°C, the spray speed of the coagulation bath is 180m / min, the distance between the converging point of the coagulation bath and the spinneret is 10mm, the spray angle of the coagulation bath (the extension line of the annular nozzle and the vertical The included angle of the direction, the same below) is 35°, and the spinning speed is 200m / min. After subsequent water washing, alkali washing, water washing, drying, oiling, and winding, the finished fibers were obtained. The mechanical properties of the fibers are shown in Table 1....

Embodiment 2

[0029] Dissolve poly-p-phenylene terephthalamide resin with a reduced viscosity of 6.3dl / g in 100% concentrated sulfuric acid at 85°C to prepare a 19.5wt% liquid crystal spinning solution, which is defoamed, filtered, and metered in sequence Finally, it is extruded from the spinneret with 0.063mm aperture, and then enters the solidification disk after passing through the air layer. The coagulation bath is 5% sulfuric acid solution, the temperature is 5°C, the spray speed of the coagulation bath is 300m / min, the distance between the converging point of the coagulation bath and the spinneret is 10mm, the spray angle of the coagulation bath (the extension line of the annular nozzle and the vertical The included angle of the direction, the same below) is 30°, and the spinning speed is 330m / min. After subsequent water washing, alkali washing, water washing, drying, oiling, and winding, the finished fibers were obtained. The mechanical properties of the fibers are shown in Table 1. ...

Embodiment 3

[0031] Dissolve poly-p-phenylene terephthalamide resin with a reduced viscosity of 6.3dl / g in 100% concentrated sulfuric acid at 85°C to prepare a 19.5wt% liquid crystal spinning solution, which is defoamed, filtered, and metered in sequence Finally, it is extruded from the spinneret with 0.063mm aperture, and then enters the solidification disk after passing through the air layer. The coagulation bath is 5% sulfuric acid solution, the temperature is 5°C, the spray speed of the coagulation bath is 500m / min, the distance between the converging point of the coagulation bath and the spinneret is 13mm, the spray angle of the coagulation bath (the extension line of the annular nozzle and the vertical The included angle of the direction, the same below) is 25°, and the spinning speed is 600m / min. After subsequent water washing, alkali washing, water washing, drying, oiling, and winding, the finished fibers were obtained. The mechanical properties of the fibers are shown in Table 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com