Automatic drying machine for water-soluble fertilizer

A dryer and fertilizer technology, applied in dryers, drying solid materials, dry cargo handling, etc., can solve the problems of poor uniformity of fertilizer drying, affecting enterprise production, and long drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

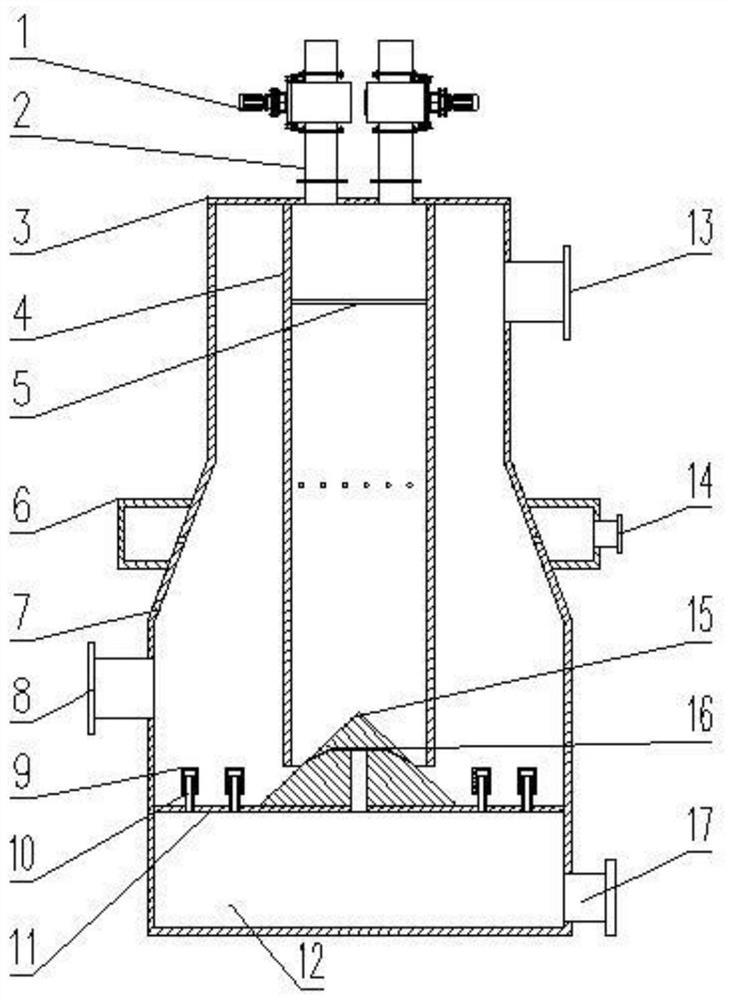

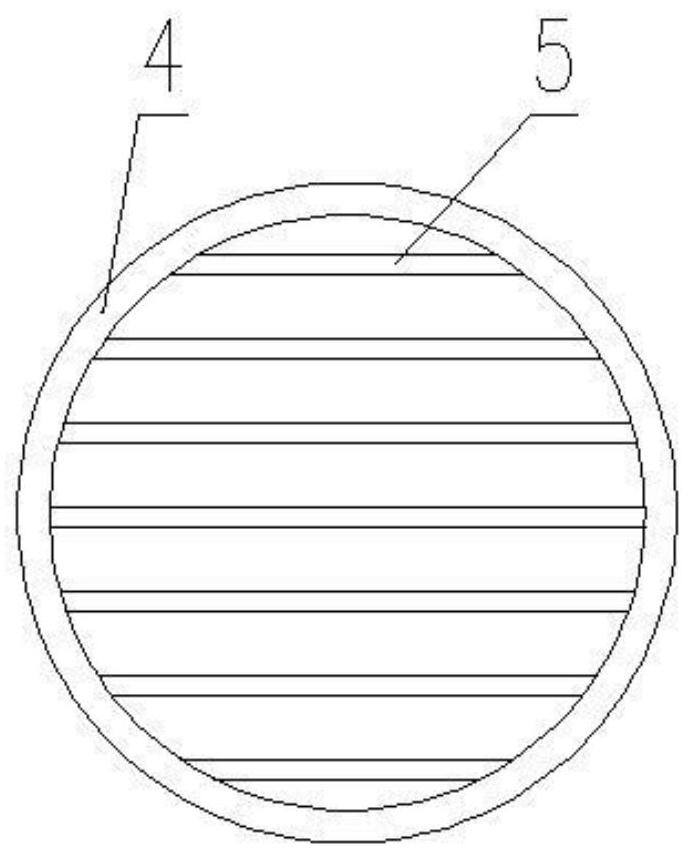

[0014] see figure 1 , figure 2 , an automatic dryer for water-soluble fertilizers, comprising a top drying chamber 3 and a drying chamber 7, characterized in that: the top drying chamber 3 is fixed on the top of the drying chamber 7, and the middle part of the top drying chamber 3 is suspended and fixed with a center Pipe 4, the lower part of the central pipe 4 is inserted into the lower part of the drying chamber 7, and the inner side of the central pipe 4 is fixed with multiple sets of distributing rods 5, and the upper part of the drying chamber 7 is a tapered cylinder structure. The lower part of the chamber 7 is fixed with an air chamber 12, the connection between the drying chamber 7 and the air chamber 12 is fixed with a fixed plate 11, and the center of the fixed plate 11 is fixed with a tapered distribution cone 15, the distribution cone 15 The upper part is inserted into the central tube 4, a gap is provided between the side of the distribution cone 15 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com