Special tool for quickly notching horn

A fast, notched technology, applied in the field of machining, to improve the quality of openings and reduce working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

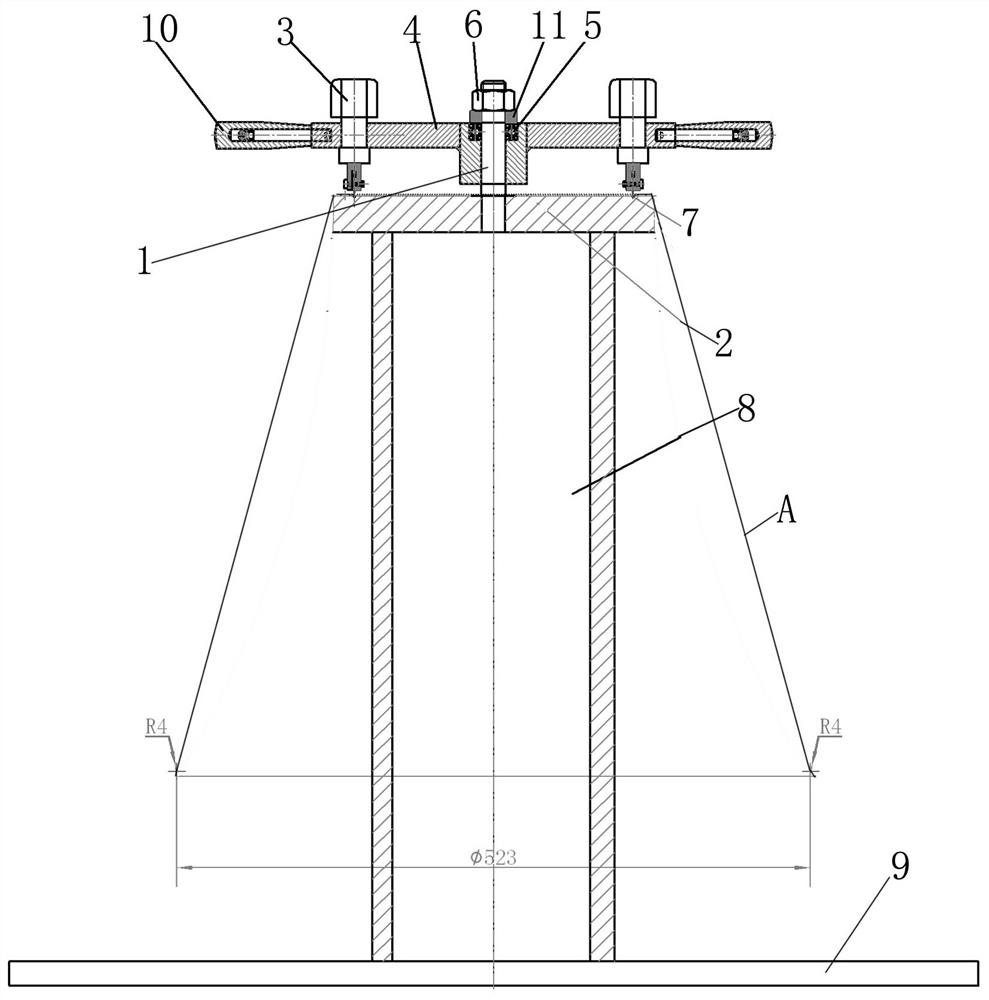

[0018] Example: see figure 1 , in the figure, 1-rotating shaft, 2-chassis mold, 3-cutting tool, 4-rotating arm, 5-thrust ball bearing, 6-compression nut, 7-ring groove, 8-bracket, 9-base plate, 10 - Rotary handle, 11- Compression washer, A- profile.

[0019] Special tooling for horn quick incision, including chassis mold, rotating mechanism and cutting tool. The middle of the rotating mechanism is fixed on the chassis mold through the rotation of the rotating shaft. The cutting tool rotates to realize the cutting of profiles; the chassis mold is disc-shaped, one end of the rotating shaft is set at the center of the chassis mold, and the other end of the rotating shaft is provided with threads; the rotating mechanism includes a rotating arm and a thrust ball bearing, which rotates The center of gravity of the arm is provided with a through hole sleeved on the rotating shaft, the rotating shaft is sleeved with a thrust ball bearing embedded in the rotating arm through an annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com