AGV and method for replacing battery of transfer robot

A technology for handling robots and batteries, which is applied in the field of transfer vehicles, can solve the problems of large battery volume and weight, low degree of automation, and poor safety, and achieve the effects of strong practicability, good adaptability, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] First of all, it needs to be explained that the orientation words such as up, down, left, right, front, and back described in the present invention are only described according to the accompanying drawings, so as to be easy to understand, and are not intended to limit the technical solution and scope of protection of the present invention. .

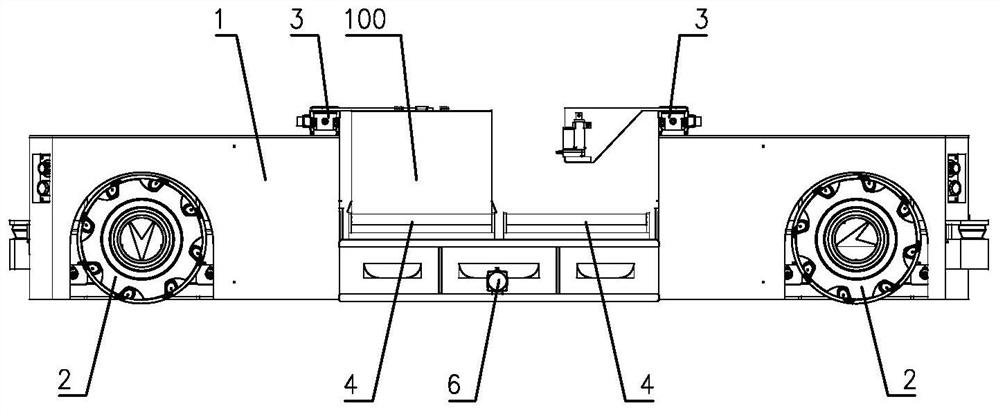

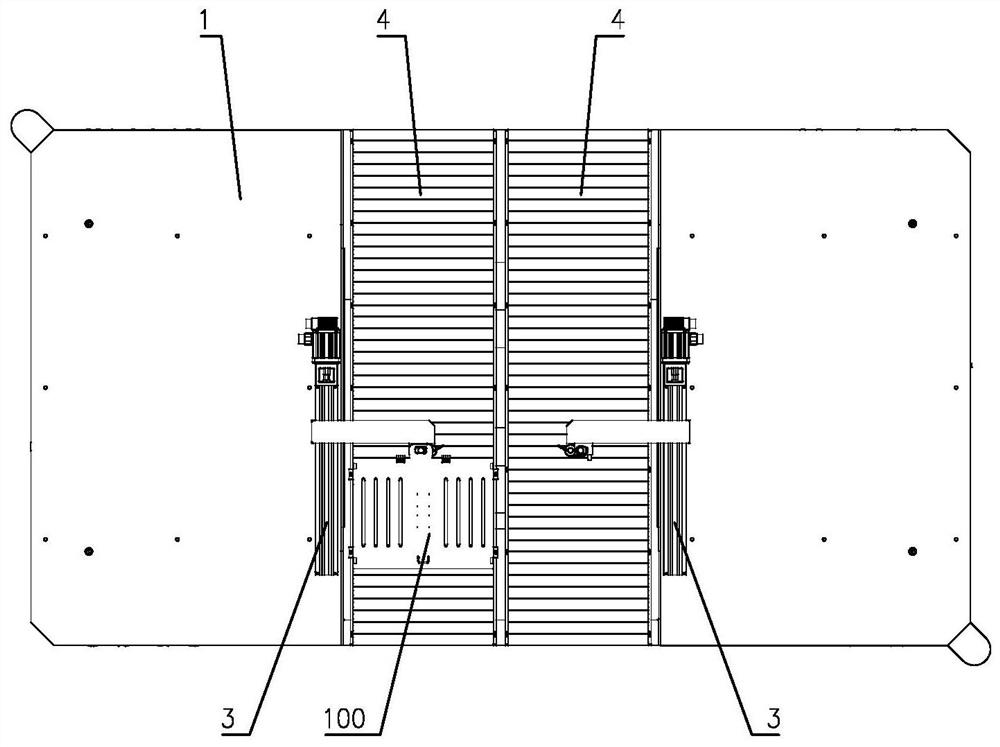

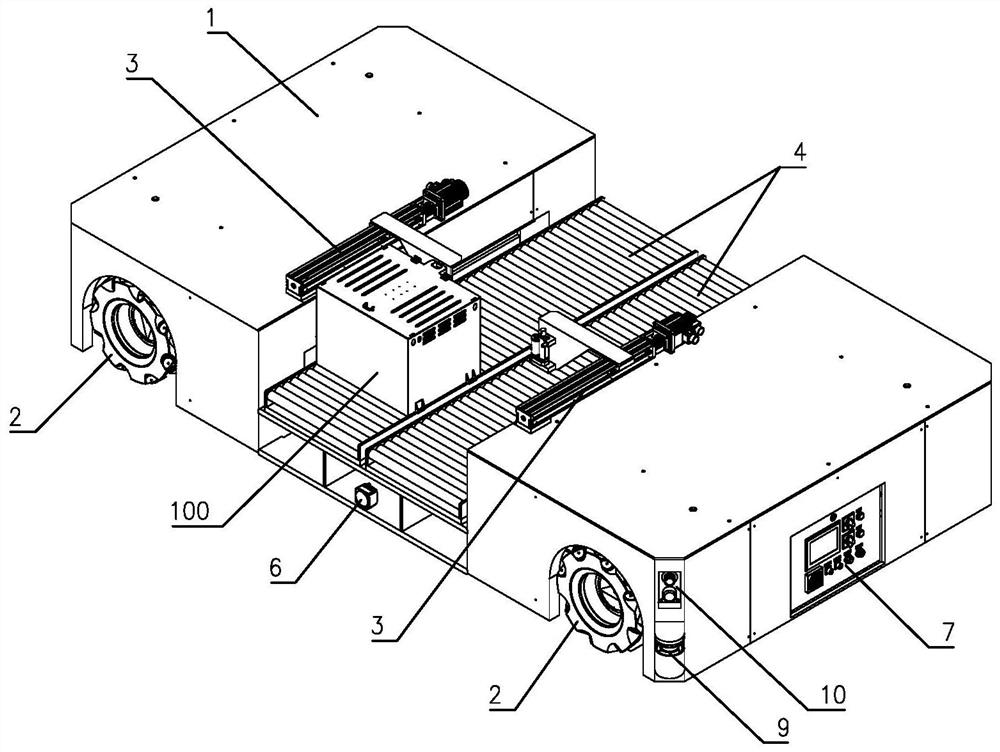

[0033] Such as Figure 1 to Figure 7 Shown is a specific embodiment of an AGV for replacing the battery of a handling robot according to the present invention, which includes a vehicle frame 1 and four Mecanum wheel sets 2 mounted on the vehicle frame 1 . Two symmetrical battery push-pull devices 3 are arranged on the vehicle frame 1, and a groove is arranged on the vehicle frame 1 between the two battery push-pull devices 3, and two rows of roller tables 4 are arranged in the groove. The battery push-pull device 3 includes a first motor 31 and a slide rail module 32 that are connected to each other and fixed on the vehicle frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com