Sealed subpackaging device for amnion gel freeze-dried powder

A technology for gel freeze-dried powder and sub-packaging, which is applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of relative position deviation between glass bottles and sub-packaging devices, complicated device operation, and glass bottle positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

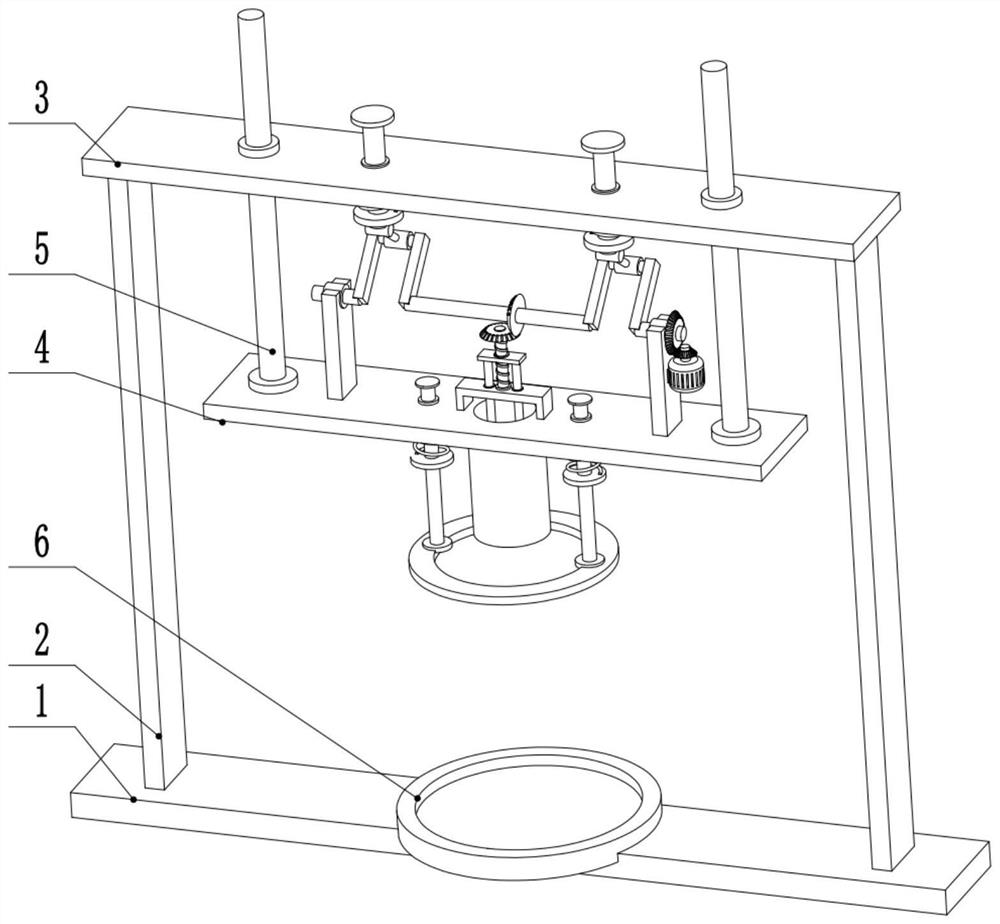

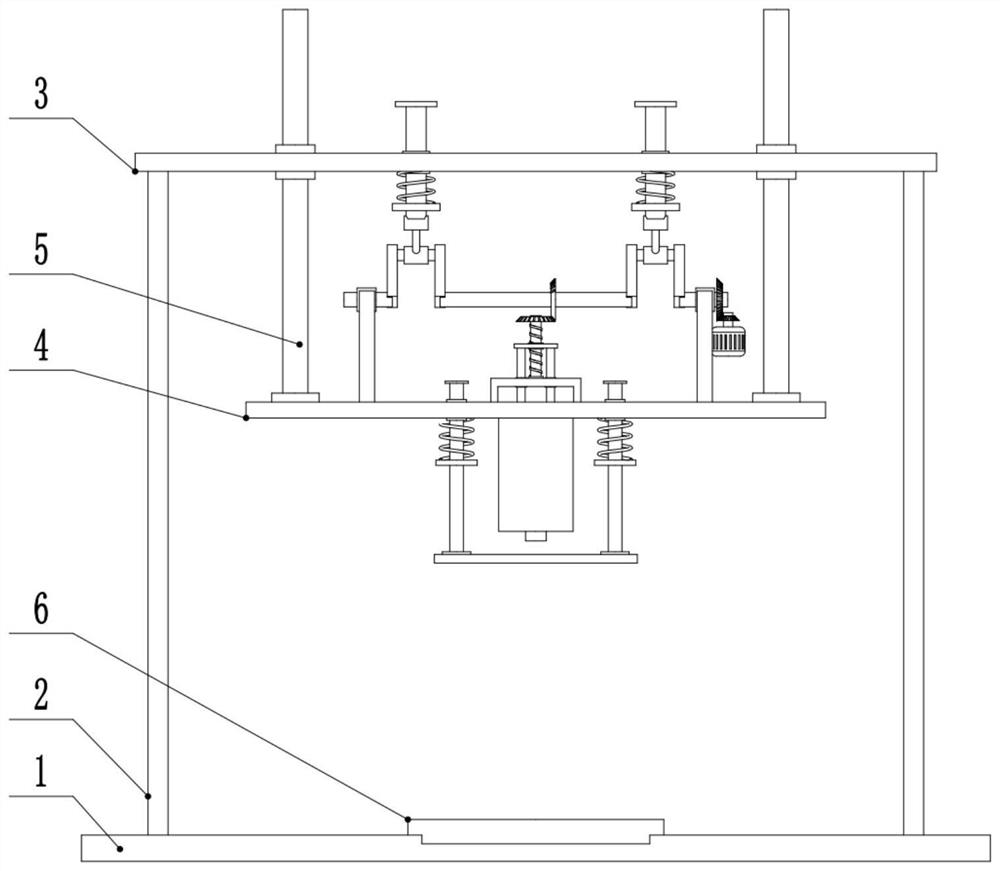

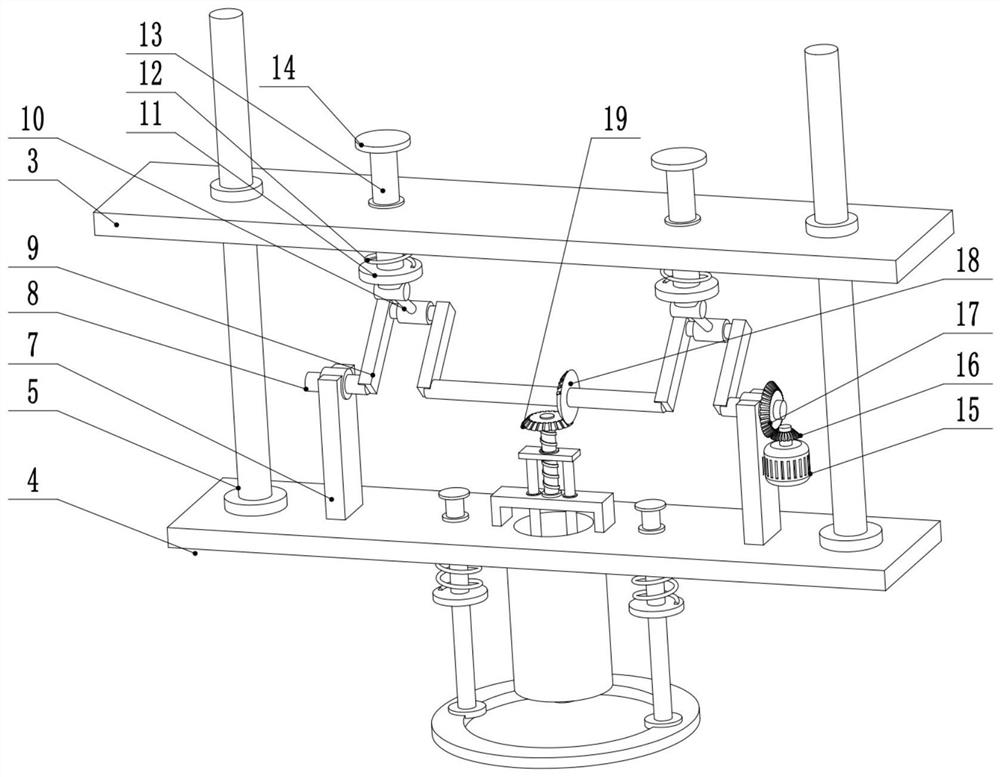

[0027] see Figure 1-5 , a kind of amniotic membrane gel freeze-dried powder sealed packaging device, comprising a base plate 1, the left and right sides of the upper surface of the base plate 1 are provided with support columns 2, the upper end of the support column 2 is provided with a top plate 3, and the left and right sides of the top plate 3 are slidingly connected The first guide rod 5, the lower end of the first guide rod 5 is fixedly connected to the left and right ends of the upper surface of the workbench 4, the middle part of the workbench 4 is provided with a through hole 21, and the middle part of the lower surface of the workbench 4 is provided with a storage barrel 30, The bottom of the storage barrel 30 is provided with an extrusion port 31 .

[0028] The left and right sides of the upper surface of the workbench 4 are provided with a first fixed plate 7, the top of the first fixed plate 7 is rotatably connected to the left and right ends of the rotating shaft...

Embodiment 2

[0032] see figure 1 , Embodiment 2 is improved on the basis of Embodiment 1, and the middle part of the upper surface of the bottom plate 1 is provided with a placing platform 6 . In order to facilitate the operator to place the storage device inside the device, a placement platform 6 is provided on the bottom plate 1, and a groove is provided on the top of the placement platform 6. The diameter of the groove is the same as the diameter of the bottom of the storage device, so When using the device, the operator only needs to place the storage device directly in the groove on the upper part of the placement table 6 to ensure that the storage device is located at the center of the device, which is convenient for subsequent sub-packaging.

[0033]In the present invention, during use, the amnion gel freeze-dried powder that needs to be subpackaged is first placed inside the storage barrel 30, and the drive motor 15 is started at this time, and the drive motor 15 is connected by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com