Device for producing high-quality building materials

A kind of building material, high-quality technology, applied in the field of cement processing, can solve the problems of unbalanced force on the device, uneven distribution, large wear noise, etc., to achieve the effect of avoiding rotation, enhancing anti-interference, and reducing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

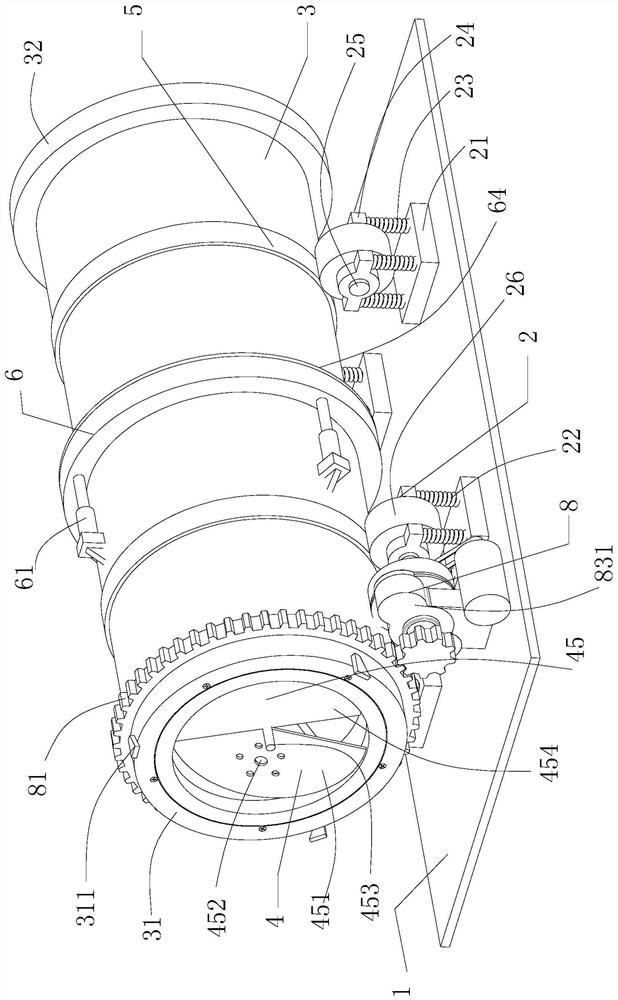

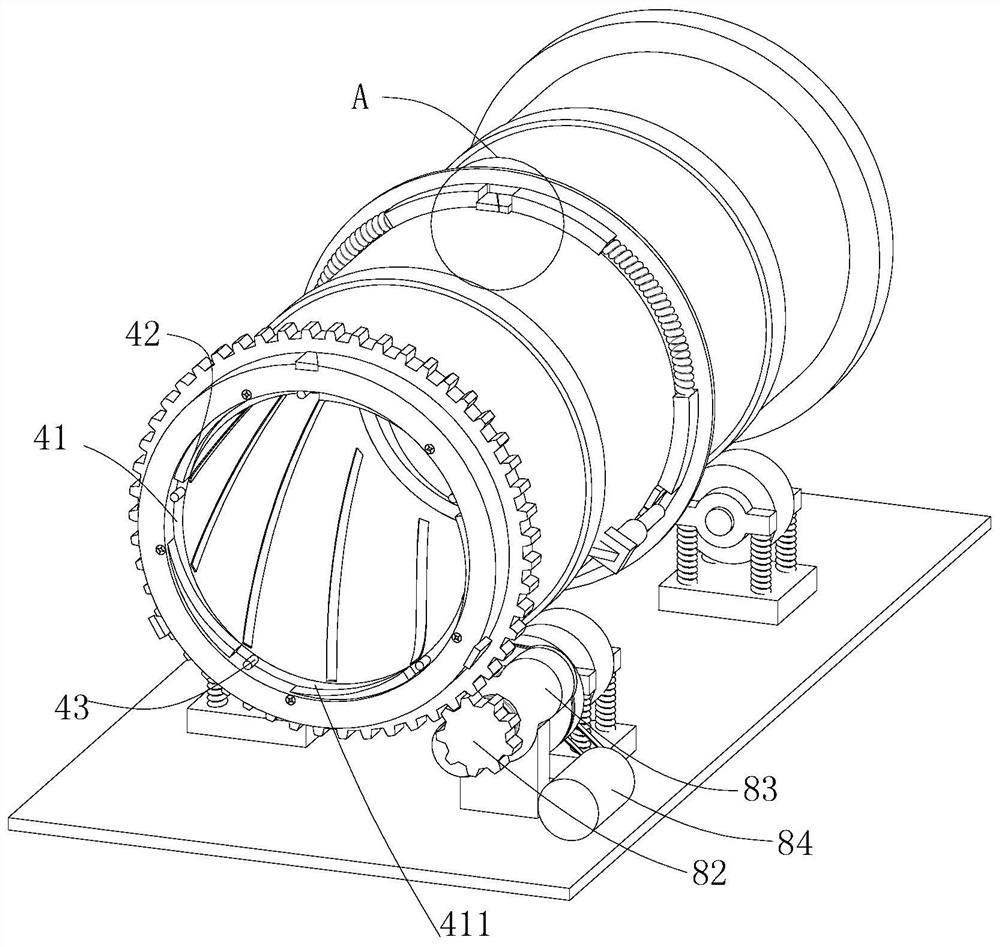

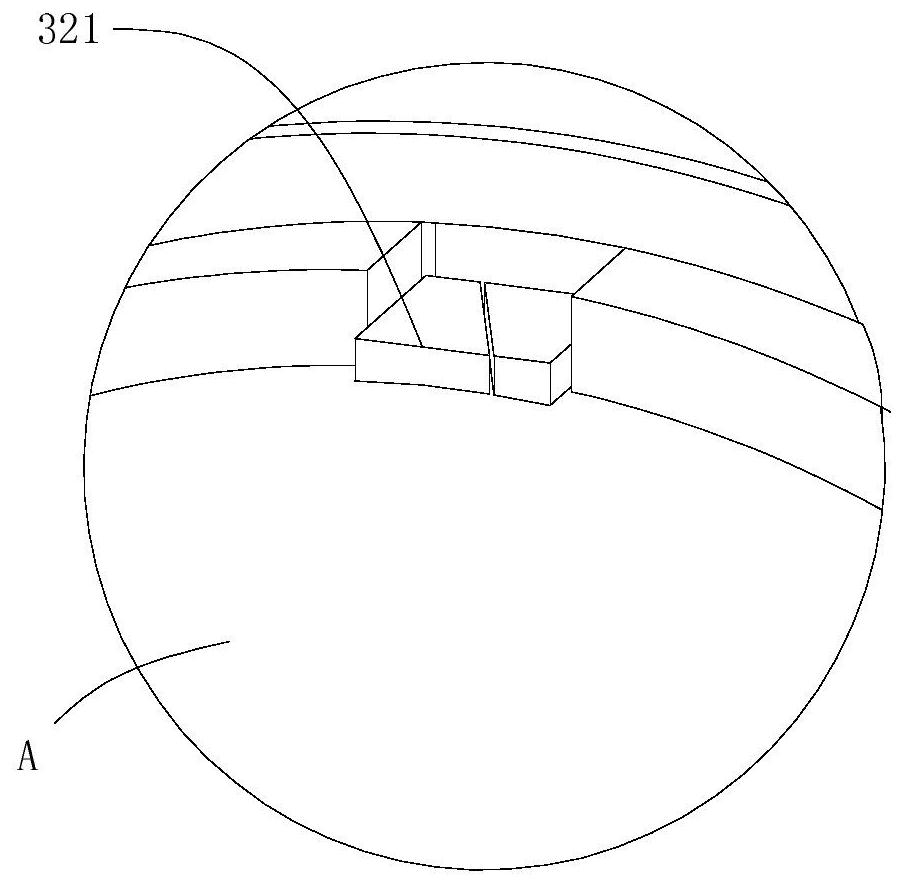

[0024] Such as Figure 1-9As shown, a device for producing high-quality building materials includes a mounting base 1, a support wheel assembly 2, a rotary kiln body 3, a kiln head 31, a sub-wedge 311, a feeding mechanism 4, a wheel belt 5, a splicing buckle 6, a hydraulic Rod 61, kiln tail 32, female wedge 321, sealing assembly 7 and pulse drive mechanism 8; the support wheel assembly 2 is fixedly installed on the installation base 1; the rotary kiln body 3 is located on the installation base 1 above; the kiln head 31 of the rotary kiln body 3 of the sub-wedge 311; the feeding mechanism 4 is located at the kiln head 31 and is rotatably connected with the kiln head 31; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com