Culture method of denitrification granular sludge for wastewater treatment

A technology of nitrification and denitrification particles and cultivation methods, which is applied in the field of cultivation of denitrification and denitrification granular sludge in wastewater treatment, can solve the problems of low denitrification efficiency and high energy consumption, and achieve good settling performance, large particle size and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

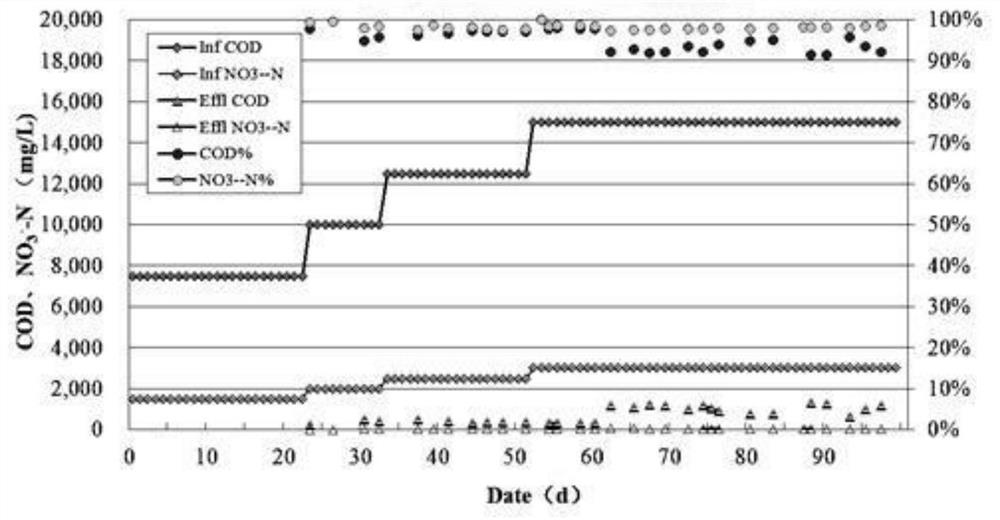

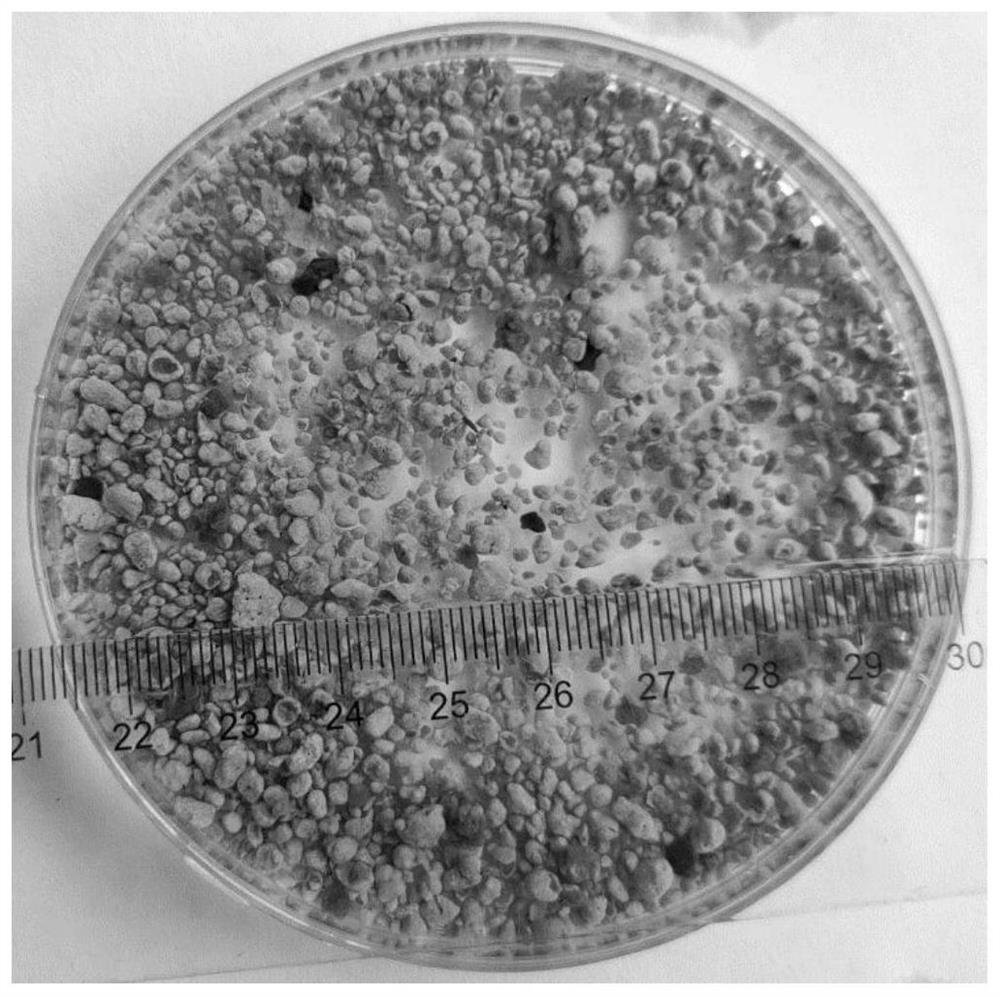

[0017] Denitrification and denitrification granular sludge reactor (effective volume 16L) was used to carry out the denitrification granular sludge cultivation test, and the denitrification flocculent sludge domesticated from the sewage treatment plant was inoculated into the denitrification and denitrification granular sludge reactor. Taking the simulated wastewater as the influent, the sludge concentration of the reactor after inoculation was 5.0g / L, and the simulated wastewater NO 3 - -N initial value is 1,000mg / L, COD initial value is 4,000mg / L, control COD concentration and NO 3 - -The ratio of N concentration is 4 to 1, and the culture is carried out under the condition of avoiding light and anaerobic while monitoring NO 3 - -N effluent situation, the culture temperature of the reactor is 32°C, the pH value is 3.5, and the hydraulic retention time is 1d. The simulated wastewater includes COD, NO 3 - -N, phosphate and trace elements Mn, Co, Cu, Zn, Ni, Mo, Se.

[00...

Embodiment 2

[0021] Denitrification and denitrification granular sludge reactor (effective volume 16L) was used to carry out the denitrification granular sludge cultivation test, and the denitrification flocculent sludge domesticated from the sewage treatment plant was inoculated into the denitrification and denitrification granular sludge reactor. Taking the simulated wastewater as the influent, the sludge concentration of the reactor after inoculation was 5.0g / L, and the simulated wastewater NO 3 - -N initial value is 1,500mg / L, COD initial value is 7,500mg / L, control COD concentration and NO 3 - -The ratio of N concentration is 5, and the cultivation is carried out under the condition of avoiding light and anaerobic while monitoring NO 3 - -N effluent situation, the cultivation temperature of the reactor is 28°C, the pH value is 6.5, and the hydraulic retention time is 2d. The simulated wastewater includes COD, NO 3 - -N, phosphate and trace elements Mn, Co, Cu, Zn, Ni, Mo, Se.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com