Low-temperature heat pump sludge drying machine with extrusion water filtering function

A technology of sludge drying and low-temperature heating, which is used in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high energy consumption, high cost, incomplete drying, etc., and achieve good drying effect, low drying cost, Solve the effect of incomplete drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

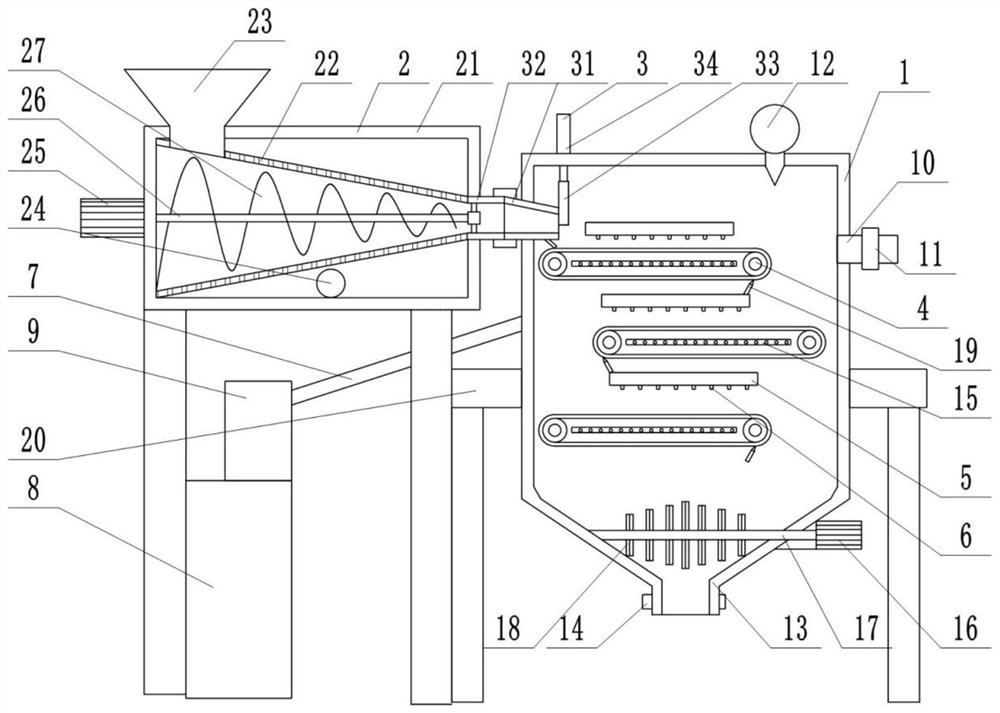

[0017] like figure 1 As shown, a low-temperature heat pump sludge dryer with the function of squeezing and filtering water includes a drying box 1, and one side of the drying box 1 is provided with a squeezing and filtering water feeding assembly 2 for feeding materials. The output end of the filtered water feeding assembly 2 is connected with a tablet press mechanism 3, and the discharge end of the tablet press mechanism 3 is located on the upper side of the drying box 1, and several mesh belts distributed up and down are installed in the drying box 1 Conveyor 4, an electric heating plate 15 is arranged in the mesh belt loop of the mesh belt conveyor 4, and the electric heating plate 15 is installed on the inner wall of the drying box 1. The discharge end of the belt conveyor 4 is located directly above the feed end of the mesh belt conveyor 4 below, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com