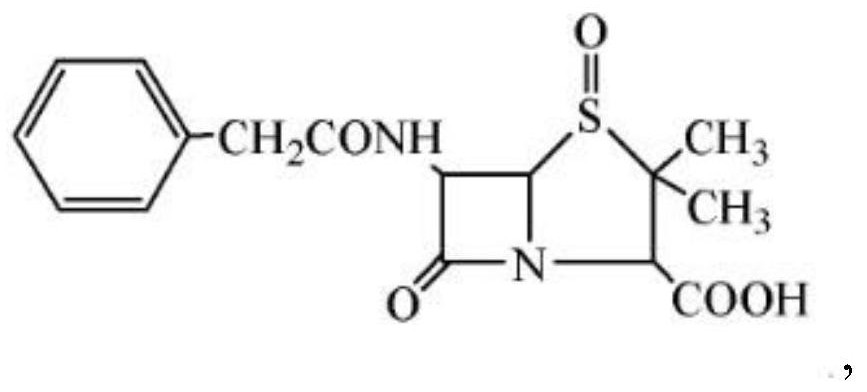

Production method of penicillin sulfoxide industrial products

A technology of penicillin sulfoxide and production method, which is applied in the field of medicine and chemical industry, can solve the problems of quality and yield reduction, difficulty in drying and separation, and achieve the effects of improved stability, easy drying and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Suspend 200 grams of penicillin sulfoxide dihydrate (content 70.2%) in 200 ml of methanol, under stirring at 10°C, add 360 ml of methanol and 50 ml of 20% ammonia water for 1 hour to dissolve in methanol aqueous solution, and filter the solution with diatomaceous earth , under the condition of stirring at 10°C, add 40ml of methanol and 200ml of 20% sulfuric acid in 1 hour to crystallize in aqueous methanol solution, grow crystals for 30 minutes, filter, wash with 200ml of 80% aqueous methanol, and dry at 50°C for 1 hour to obtain 147.6 grams of penicillin sulfoxide (content 91.5%, loss on drying 8.6%, light absorption 0.004, light transmission 95.8%), yield 96.2%.

Embodiment 2

[0037] Suspend 100 grams of penicillin sulfoxide methanolate (content 90.6%) in 100 ml of methanol, under stirring at 10°C, add 30 ml of methanol and 25 ml of 20% ammonia water for 1 hour to dissolve in methanol aqueous solution, and filter the solution with diatomaceous earth. Under stirring conditions at 10°C, add 20ml of methanol and 100ml of 20% sulfuric acid in 1 hour to crystallize in an aqueous methanol solution mixed with crystallization for 30 minutes, filter, wash with 100ml of 80% aqueous methanol, and dry at 50°C for 1 hour to obtain 95.8 grams of penicillin sulfoxide (content 91.6%, loss on drying 8.6%, light absorption 0.002, light transmission 98.2%), yield 96.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com