A 3D printing processing method of a conductive partition plate with a gas-liquid distribution flow field

A gas-liquid distribution and separation plate technology, which is applied in the field of electrochemistry, can solve problems such as high positioning accuracy requirements, high positioning accuracy requirements, and increased processing costs, to ensure assembly quality and positioning accuracy, simplify assembly processes, and reduce The effect of leakage risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

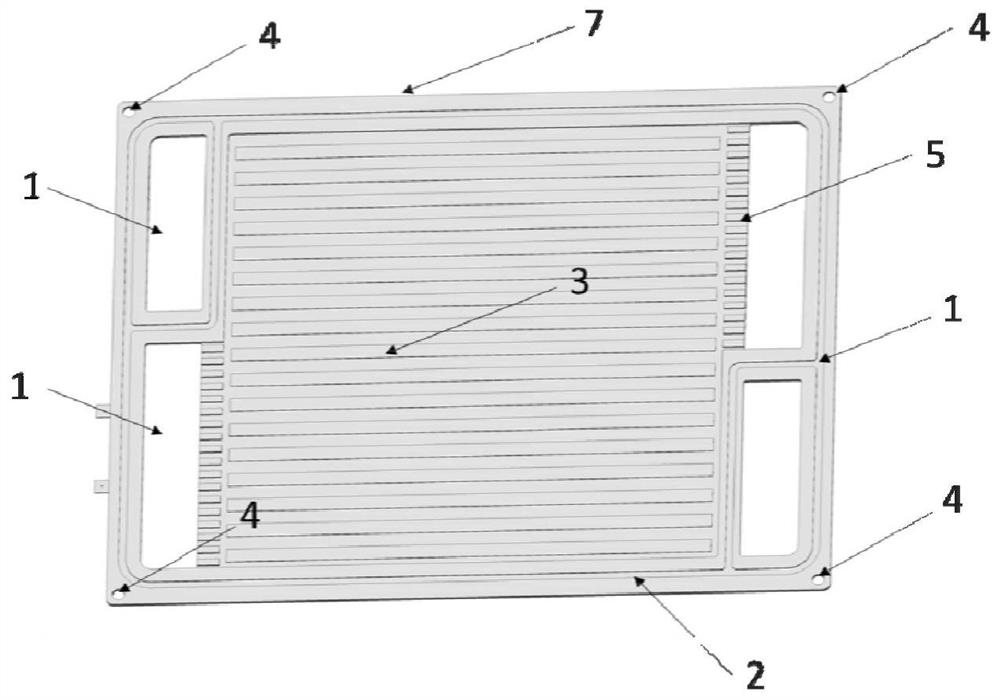

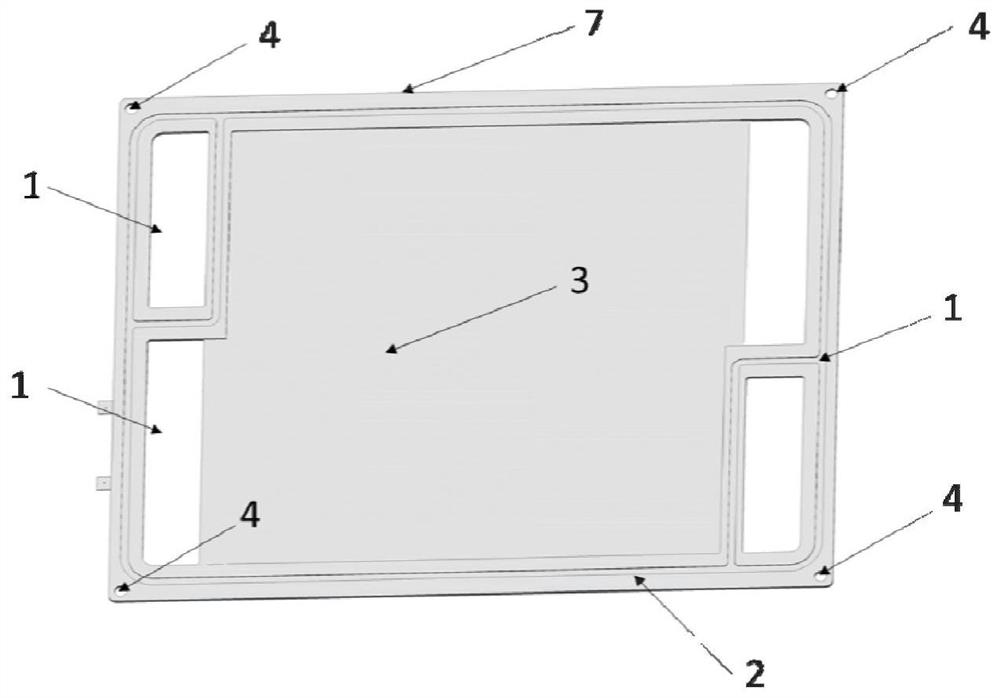

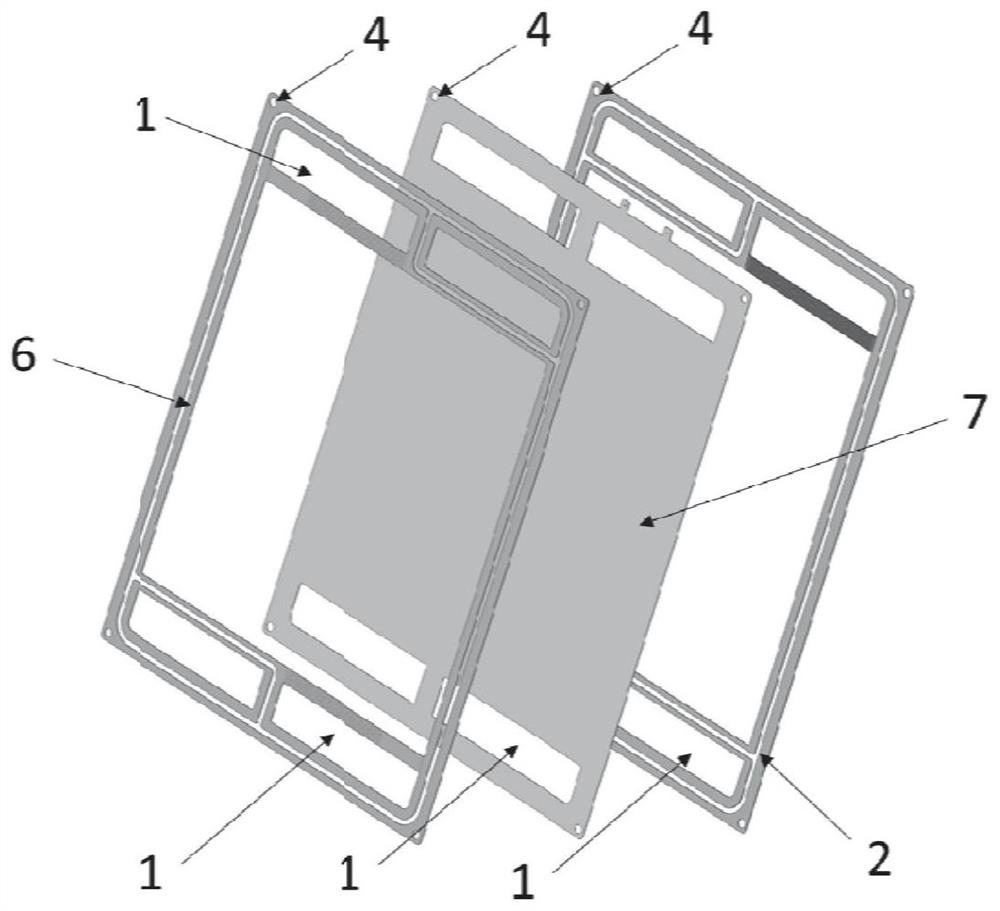

[0041] A 3D printing processing method based on the above-mentioned conductive separator with a gas-liquid distribution flow field structure, comprising the following steps:

[0042] 1. Three-dimensional modeling: According to the shape and size of the conductive partition to be printed, design the shape of each functional area, the shape of the cut surface, etc.; make a three-dimensional model diagram of the designed conductive partition in the computer, and print the three-dimensional model Two-dimensional slicing of the graph;

[0043] 2. Prepare printing materials: Prepare spherical titanium powder with a particle size of 50 microns and a binder in a ratio of 10:1 to make printing materials;

[0044] 3. Input the modeling graphics in step 1 into the 3D printing program according to the format, and send the printing materials prepared in step 2 into the printing device. Printing materials alternately printed and stacked;

[0045] 4. The control component starts the convey...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com