Electromagnetic wave shielding film

An electromagnetic wave and shielding film technology, applied in the field of electromagnetic wave shielding film, can solve problems such as adverse health effects, signal interference or failure, and achieve the effects of excellent mechanical strength, flexibility, and excellent electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The metal foam is a copper metal foam in which a copper foam having a porosity of about 70% or so and a pore size of about 90% or more of pores determined by the above method is 10 μm is used. This metal foam is produced in the following manner. 130g average particle diameter (median diameter, D50 particle diameter) is the copper powder of about 60 μm, 110g texanol, 14g isobutyl isobutyrate, 6g ethylcellulose and 2g leveling agent (ACME Co., Ltd. , Surfadol 338) were mixed to prepare a slurry. The slurry is coated in the form of a film with a thickness of around 350 μm, dried in an oven at 120°C for 30 minutes, and then sintered at around 1,000°C in a hydrogen / argon atmosphere for about 2 hours to produce metal foam.

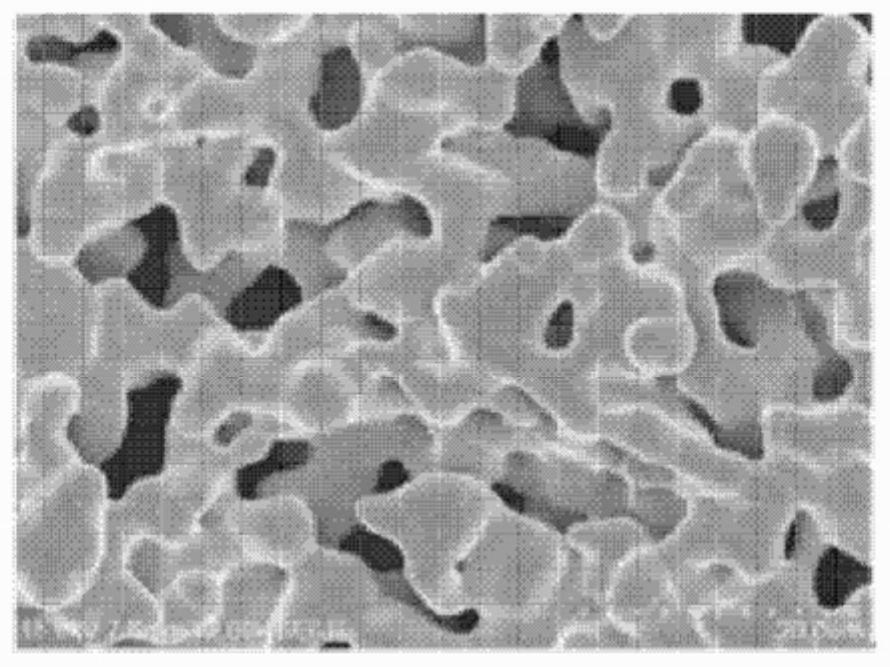

[0072] figure 1 It is the photo of the copper foam used in Example 1. The copper metal foam was dipped into a thermosetting silicone resin (Dow Corning, PDMS) and the excess composition was removed using a film applicator such that the thickness of the...

Embodiment 2

[0074]The metal foam is a copper metal foam in which a copper foam having a porosity of about 70% or so and a pore size of about 90% or more of pores determined by the above method of 50 μm is used. The metal foam was produced in the same manner as in Example 1, except that it was used by adding to the slurry applied in Example 1 10 g of polymeric foam with an average particle size (median particle size, D50 particle size) of about 50 μm. Slurries prepared with beads as an additional component. A composite material was produced using metal foam in the same manner as in Example 1. The electromagnetic wave shielding efficiency of the electromagnetic wave shielding film determined by the above method was about 95 dB or more at 100 kHz to 3 GHz and about 85 dB or more at 1.5 GHz to 18 GHz.

Embodiment 3

[0076] The metal foam is a copper metal foam in which a copper foam having a porosity of about 70% or so and a pore size of about 90% or more of pores determined by the above method is 100 μm is used. The metal foam was produced in the same manner as in Example 1, except that it was used by adding to the slurry applied in Example 1 10 g of polymeric foam with an average particle size (median particle size, D50 particle size) of about 100 μm. Slurries prepared with beads as an additional component.

[0077] A composite material was produced using metal foam in the same manner as in Example 1. The electromagnetic wave shielding efficiency of the electromagnetic wave shielding film determined by the above method was about 90 dB or more at 100 kHz to 3 GHz and about 75 dB or more at 1.5 GHz to 18 GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com