Lasting waterproof slim mascara cream and preparation method thereof

A mascara and slender technology is applied in the field of durable waterproof slender mascara and its preparation, which can solve the problems of single function of mascara, inability to resist sweat and water resistance, and not lasting makeup, and achieves increased film-forming effect and is not easy to stick. Link block, easier to paint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] How to prepare mascara:

[0043] S1. Mix microcrystalline wax, VP / eicosene copolymer, trihydroxystearin, stearyl inulin, hydrogenated polyisobutene and isododecane, stir at 85-90°C until dissolved, weigh and calculate Isododecane is volatilized and lost, and the isododecane lost by volatilization is supplemented to obtain phase A;

[0044] S2. Disperse trimethylsiloxysilicate and dimethylsilyl silica in sequence in cyclopentasiloxane at a rotational speed of 800-15000rpm / min to obtain phase B, Add phase B to phase A and disperse evenly;

[0045] S3. Put preservatives, silica, thickeners, and colorants into phase A + phase B in sequence, and stir at a speed of 3000-6000rpm / min for 4-7min, then grind them evenly, and put them at 50-60°C Add rayon fibers and cellulose, stir evenly at a rotating speed of 2000-4000rpm / min, cool down to 30-35°C, and obtain the mascara.

[0046]Examples of long-lasting waterproof lengthening mascara

Embodiment 1

[0048] S1. Heat microcrystalline wax, VP / eicosene copolymer, trihydroxystearin, stearyl inulin, hydrogenated polyisobutene, and isododecane to 85-90°C to dissolve completely, and weigh to calculate isododecane The volatilization of dioxane is lost, and the isododecane lost by volatilization is replenished to obtain phase A;

[0049] S2. Under the stirring state, the rotation speed is 1000rpm / min, and trimethylsiloxysilicate and dimethylsilyl silica are dispersed in cyclopentasiloxane in turn until the solution is half Transparent, get B phase, add B phase to A phase and disperse evenly;

[0050] S3. Add preservatives, silica, thickeners, and colorants into phase A + phase B in sequence, and stir for 5 minutes at a speed of 3000rpm / min, and then grind them evenly, then add rayon fibers at 50-60°C and cellulose, and stirred at a rotating speed of 3000rpm / min for 5min, and cooled to 30-35°C to obtain the mascara.

[0051] Among them, the raw material of mascara is 0.15kg of tri...

Embodiment 2-13

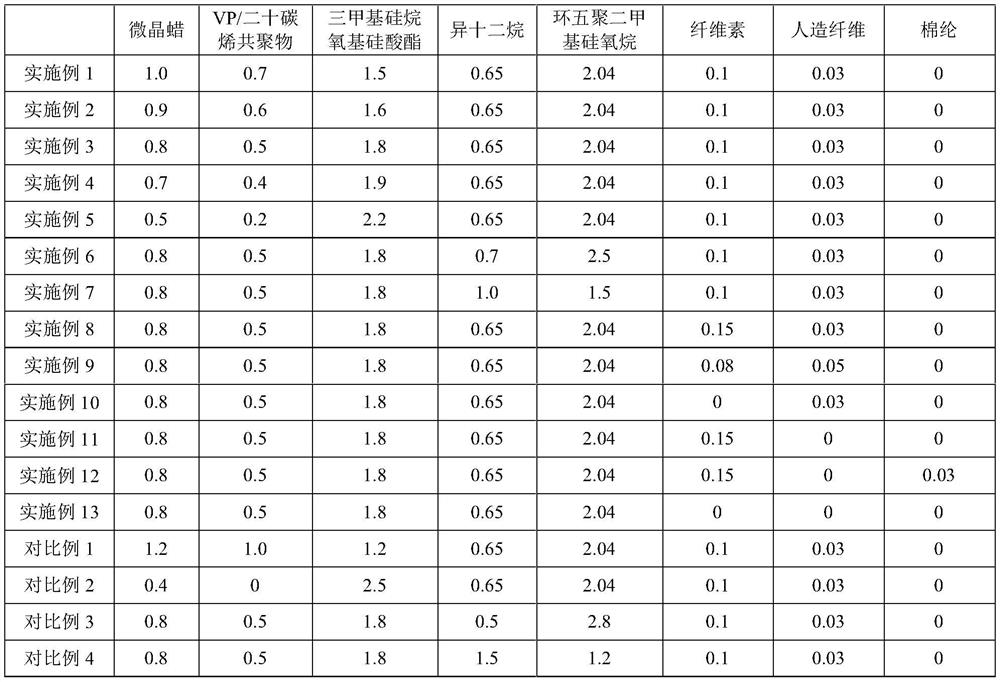

[0052] Examples 2-13: The difference from Example 1 is that some raw material formulations in the mascara are different, as shown in Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com