Crop straw impurity removing machine

A technology for crop stalks and miscellaneous machines, which is applied in the direction of solid separation, filter screen, grille, etc., which can solve the problems of increased production costs, easy to be worn, and inability to completely remove impurities, etc., to achieve increased service life, less wear, and reduced production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

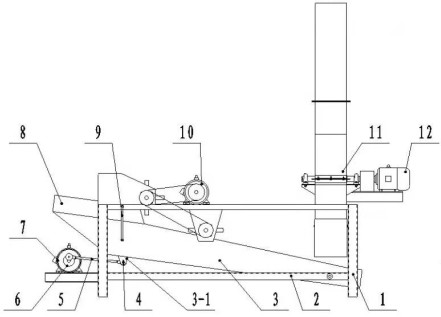

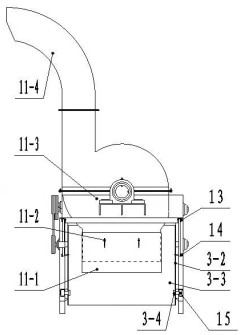

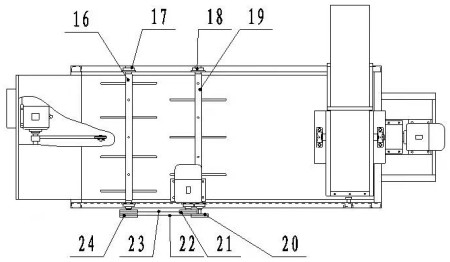

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The present invention provides a crop straw removal machine, including a frame (1), a guide rail (2), a vibrating screen (3), a connecting pin I (4), and a guide rod (5) ), eccentric wheel (6), motor Ⅰ (7), feeding inlet (8), swing rod (9), motor Ⅱ (10), conveying device (11), motor Ⅲ (12), connecting pin Ⅱ (13) , connecting pin Ⅲ (14), pulley (15), mowing roller Ⅰ (16), bearing housing Ⅰ (17), bearing housing Ⅱ (18), mowing roller Ⅱ (19), pulley Ⅰ (20), pulley Ⅱ (21), belt Ⅰ (22), belt Ⅱ (23), pulley Ⅲ (24), coupling ear (3-1), side plate (3-2), screen (3-3), pulley rod ( 3-4), adjust material opening (11-1), bolt (11-2), blower fan (11-3), and throwing material opening (11-4).

[0014] When working, first adjust the adjusting feed port (11-1) in the conveying device (11) to an appropriate position through the bolt (11-2), then start the motor III (12) to start the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com