Cleaning and drying device for mechanical part machining

A technology of drying device and spare parts, applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of low cleaning efficiency, inability to dry, difficult to popularize and apply, etc., so as to realize recycling and improve treatment. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

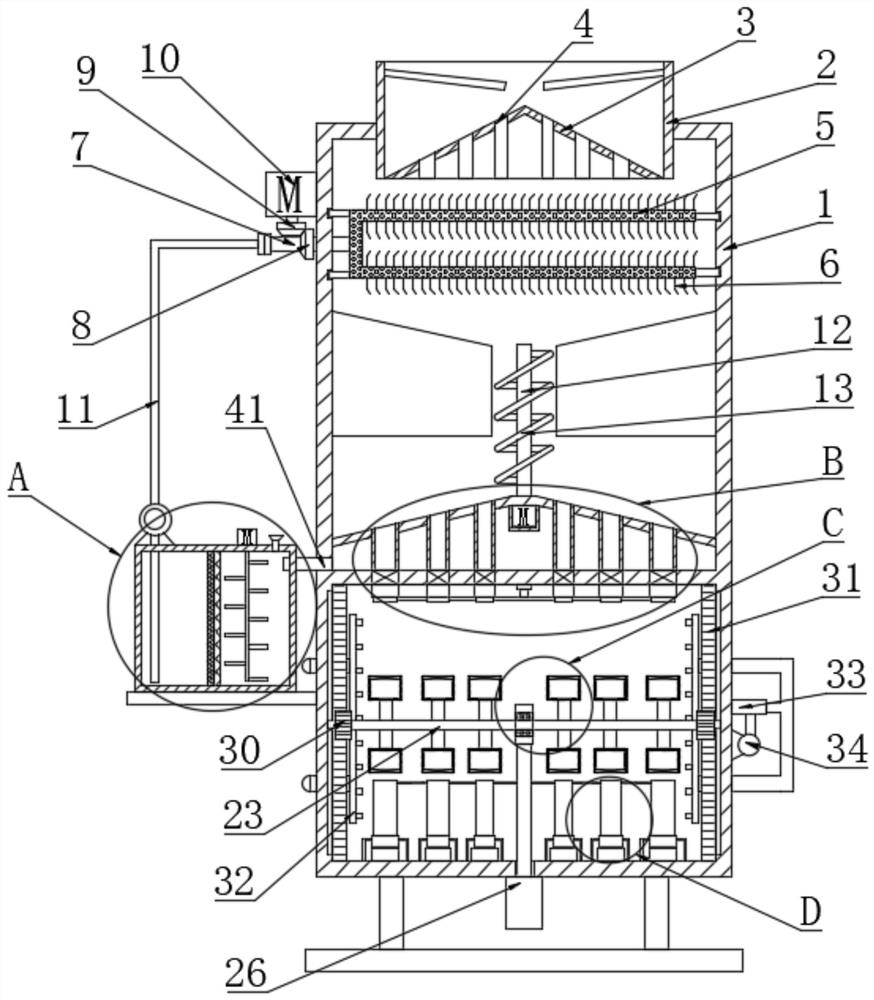

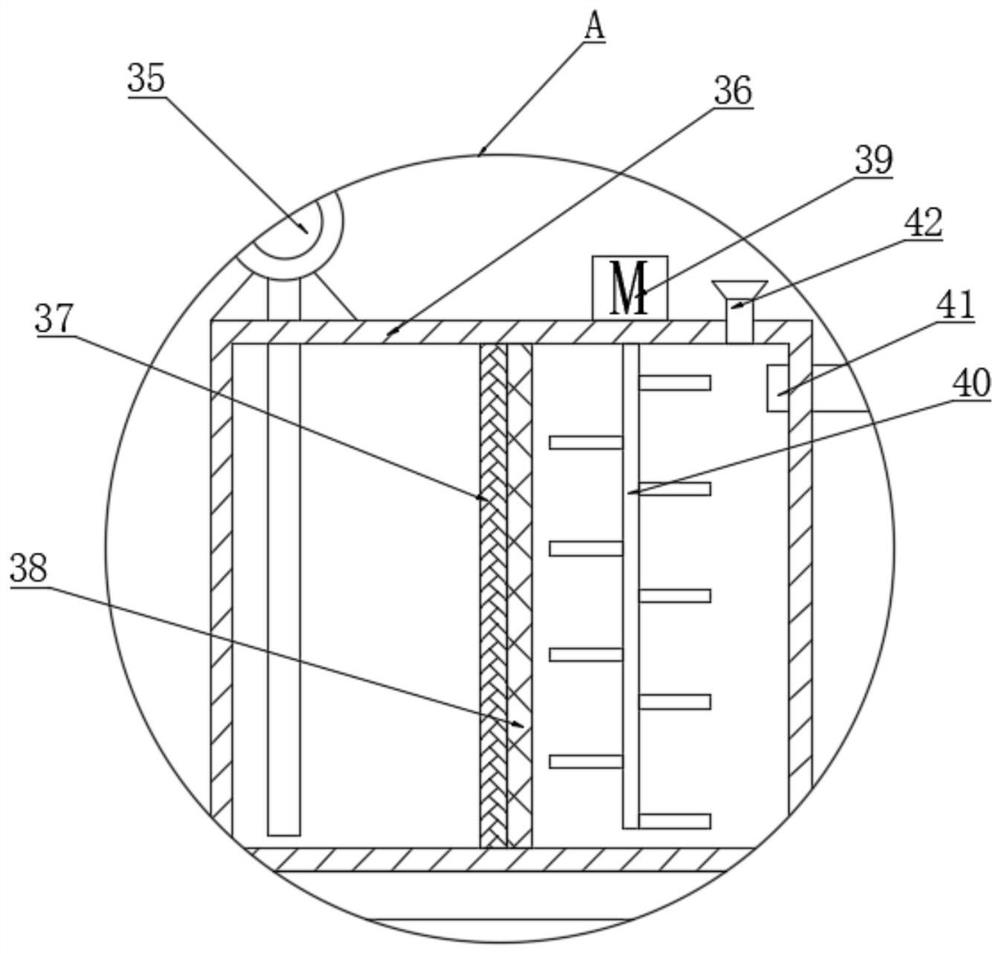

[0028] see Figure 1 to Figure 6, a cleaning and drying device for mechanical spare parts processing, comprising an equipment box 1, the top of the equipment box 1 is provided with a feed hopper 2 for feeding materials, and the inside of the feed hopper 2 is provided with a buffer plate and a first The material distribution assembly, the first material distribution assembly includes a first material guide plate 3 and a first material guide pipe 4, a cleaning assembly is provided below the first material guide pipe 4, and the cleaning assembly includes a water spray pipe 5 and the brush 6, the water spray pipe 5 is provided with a number of through holes for water outlet, the water spray pipe 5 is connected with the first rotating drive assembly through the first connecting pipe 7, and the first rotating drive assembly includes the first rotating drive assembly. One bevel gear 8, the second bevel gear 9 and the first motor 10, the first connecting pipe 7 is connected with a wat...

Embodiment 2

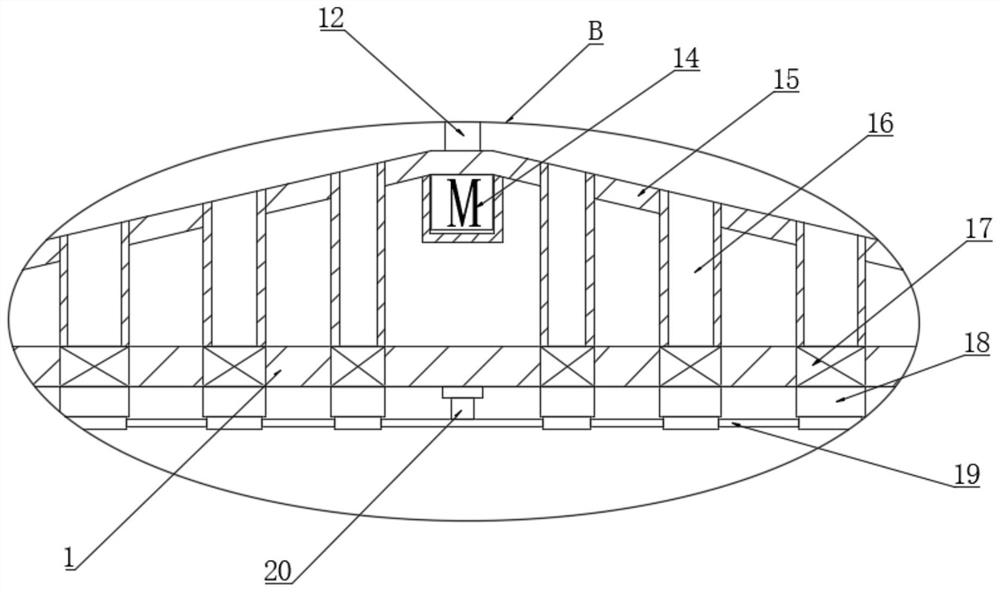

[0037] see Figure 1 to Figure 6 , a washing and drying device for processing mechanical parts, including an equipment box 1, and a first material guide assembly, the first material guide assembly includes a first telescopic sleeve 18 and a first cylinder 20, the first The bottom of the telescopic sleeve 18 is provided with a drying cylinder 21 which is convenient for placing spare parts. The drying cylinder 21 is provided with a number of through holes. Drive assembly, the second rotary drive assembly includes a rotating gear 30, a gear bar 31 and a second cylinder 26, a second material guide assembly is provided below the drying cylinder 21, and the second material guide assembly includes a second Telescopic sleeve 28, the bottom of described second telescopic sleeve 28 is provided with the collecting barrel 29 that is convenient to accommodate, and the both sides of described drying cylinder 21 is provided with drying assembly, and described drying assembly comprises jet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com