Evaluation Method of Tool Wear State of CNC Machine Tool

A tool wear, CNC machine tool technology, applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc., can solve the problems of a single decision algorithm, large fluctuations in model prediction performance, poor versatility, etc., to reduce production costs , better prediction effect, better generality and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

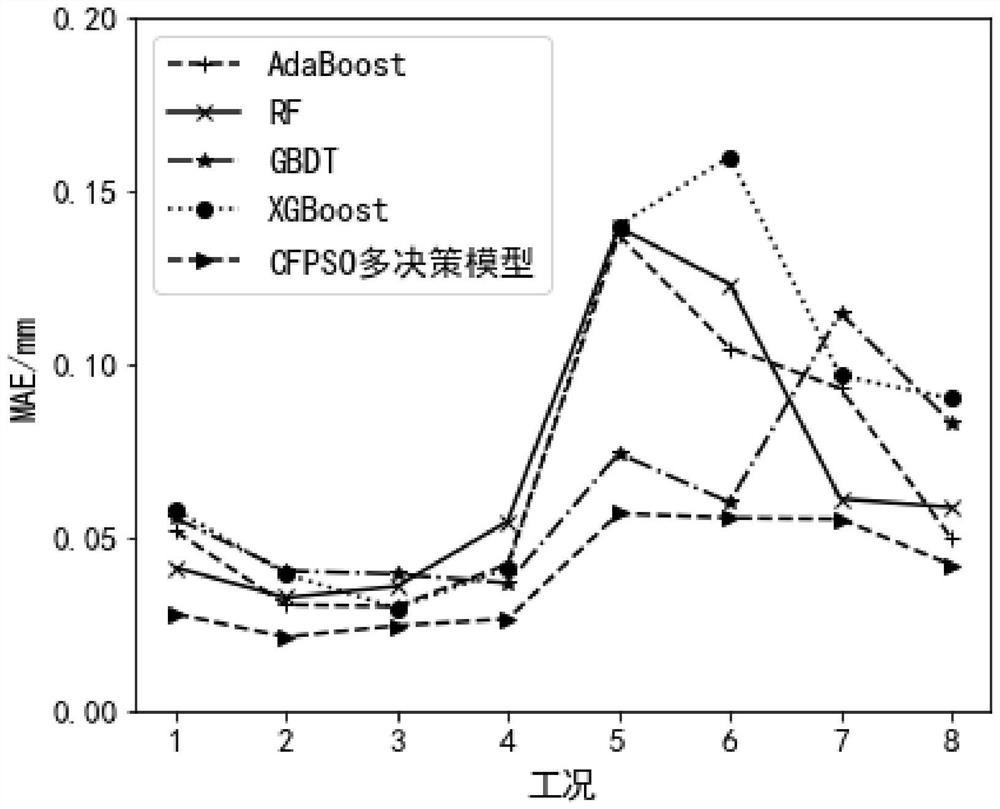

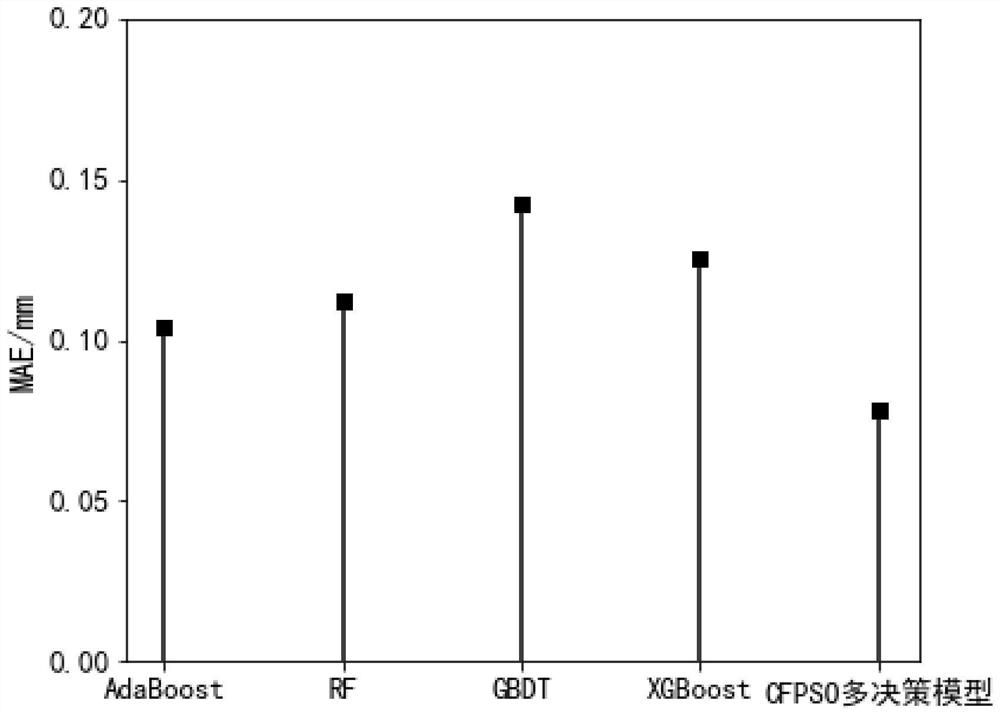

[0019] In this embodiment, the MATSUURA MC-510V machining center was measured, and the milling test was carried out under 8 different working conditions, in which the cutting depth, the feed speed, and the workpiece are variable working parameters, the cutting depth is set to 1.5 MM and 0.75mm, the feed speed is set to 0.5mm / R and 0.25mm / r, and the material material is stainless steel and cast iron, respectively. Under each condition condition, the test uses a new tool for multiple processing. When machining, the spindle current signal and the vibration signal are collected, and the tool Vb value is recorded each time until the tool VB value exceeds the threshold. The group test ends.

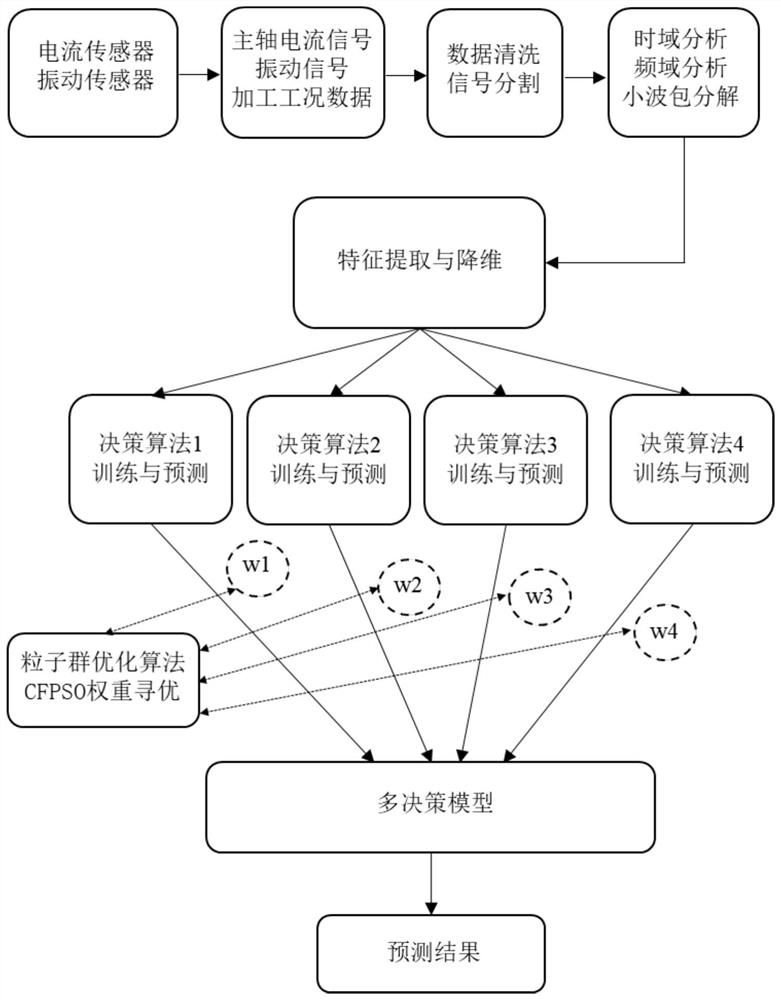

[0020] like figure 1 As shown, for the present embodiment, a method of evaluating a CNC machine tool wear condition, and the specific steps include:

[0021] Step 1) Treat analysis of the collected spindle current signal and vibration signal, select its normal cutting phase signal, extract the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com