A kind of melt-blown activated carbon non-woven fabric production process

A technology of activated carbon non-woven fabric and production process, which is applied in the direction of textile, layered products, non-woven fabrics, etc. It can solve the problems of inability to absorb odor or peculiar smell, poor antibacterial adsorption, residual activated carbon particles, etc., and achieve the goal of good products The effects of diversity, good equipment compatibility, and good odor adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

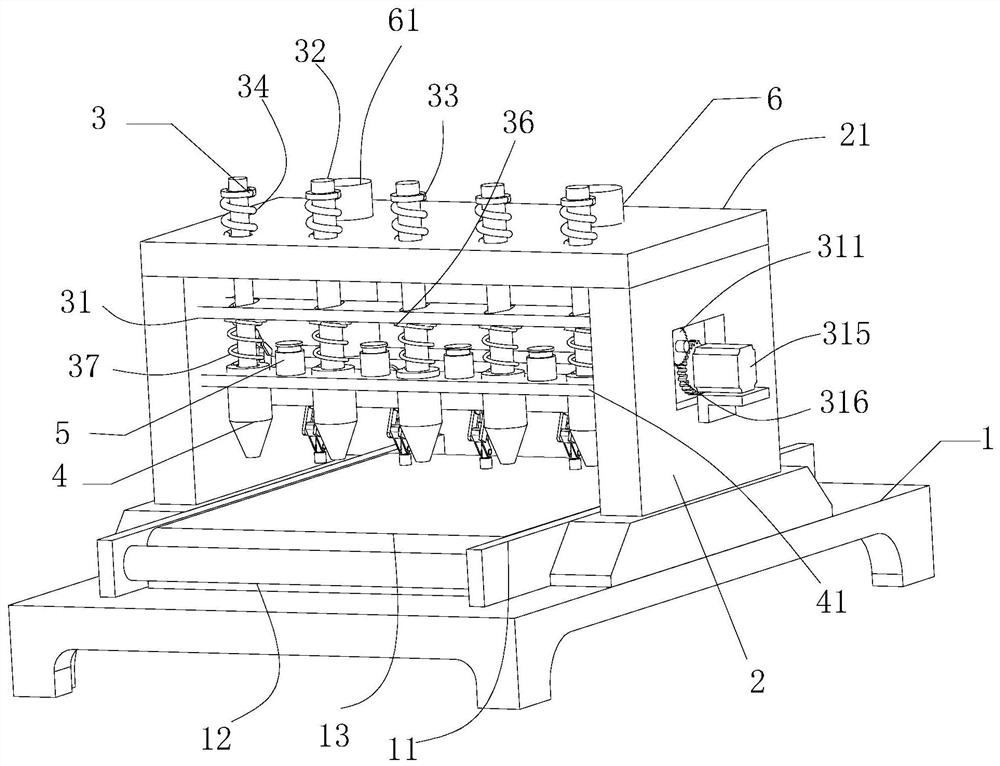

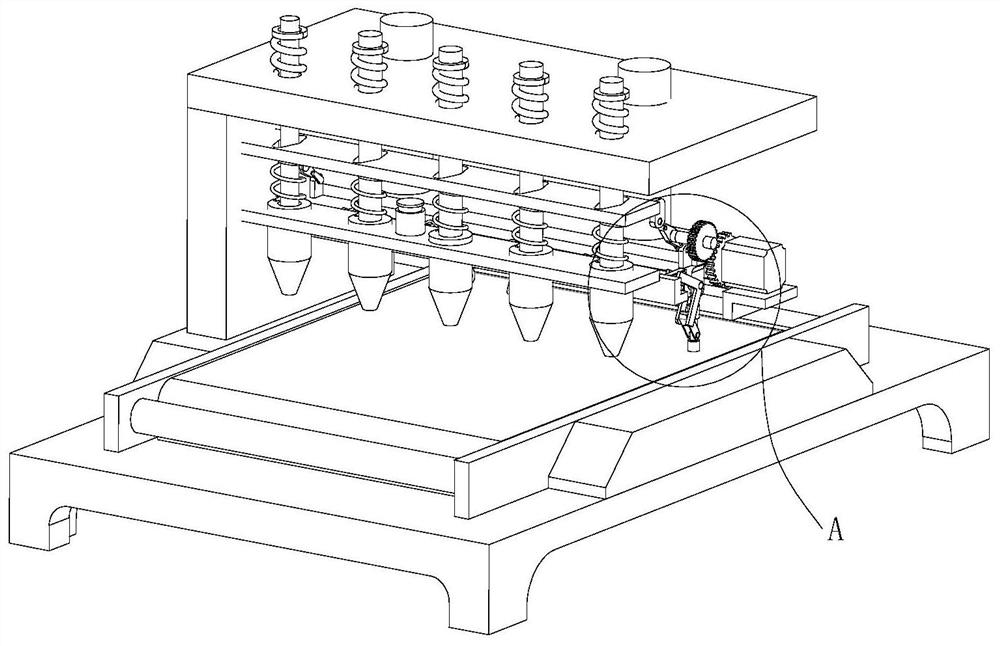

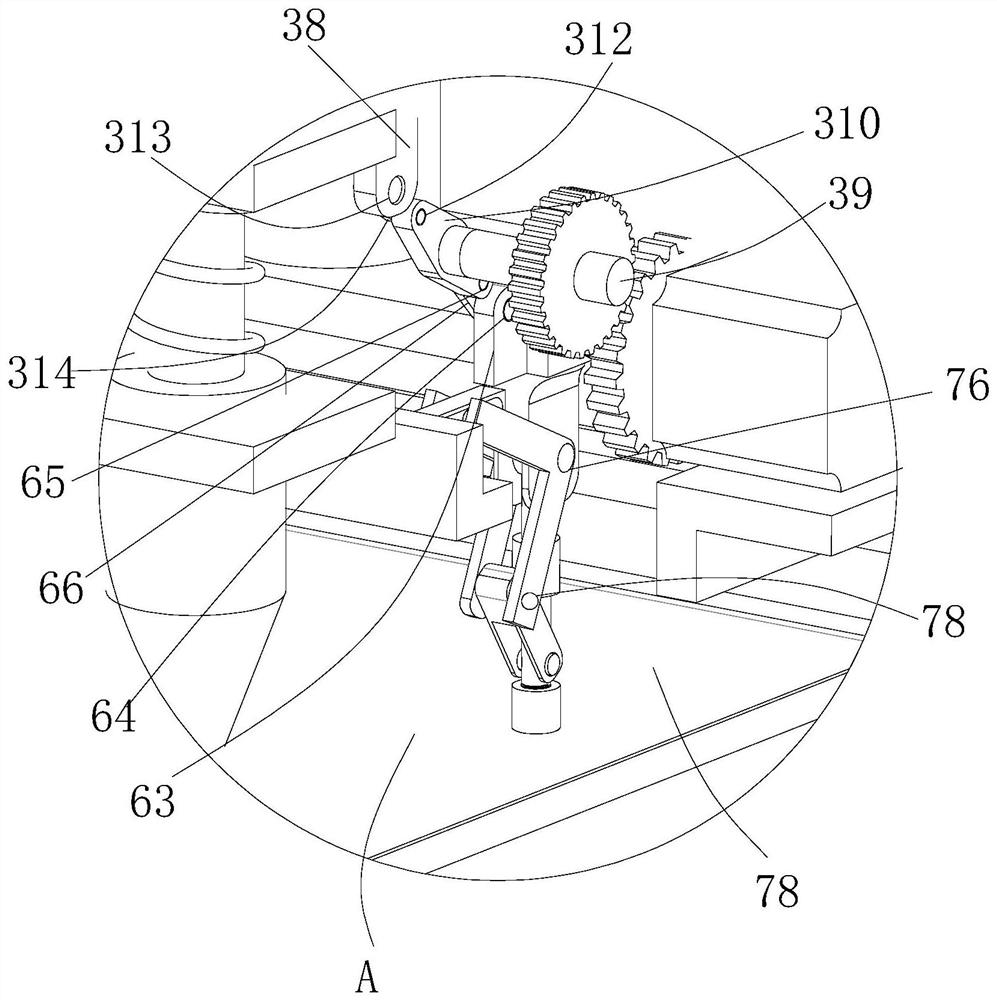

Image

Examples

Embodiment 1

[0027] A production process of melt-blown activated carbon non-woven fabric, comprising the following steps:

[0028] (1) Preparation of upper layer fabric: take PET chips as the main raw material, send dry nano-silver ion antibacterial masterbatch and PET chips into a screw extruder for blending and melting to make a spinning melt, which is filtered through a melt filter Then, it is sent to the spinning box through the melt pipeline, and measured by the metering pump, the blended melt is spun, cooled, drawn, and rolled by the spinning assembly in the spinning box to obtain PET antibacterial filament, nano-silver The content of the ionic antibacterial masterbatch is 3 to 8 wt%, and the filaments are woven into a knitted fabric by a knitting machine; then a first coating glue is formed by applying glue on the lower surface of the knitted fabric using a Tibetan powder gluer , so that the first coating glue is formed into regularly spaced circles, distributed on the lower surface...

Embodiment 2

[0040] (1) Preparation of upper layer fabric: take PET chips as the main raw material, send dry nano-silver ion antibacterial masterbatch and PET chips into a screw extruder for blending and melting to make a spinning melt, which is filtered through a melt filter Then, it is sent to the spinning box through the melt pipeline, and measured by the metering pump, the blended melt is spun, cooled, drawn, and rolled by the spinning assembly in the spinning box to obtain PET antibacterial filament, nano-silver The content of the ionic antibacterial masterbatch is 6wt%, and the filaments are woven into a knitted fabric by a knitting machine; The first coating glue is formed into regularly spaced circles and is distributed on the lower surface of the knitted fabric, and the coating area of the first coating glue accounts for 50% of the lower surface area of the knitted fabric. After completion, evenly sprinkle a layer of uniformly mixed activated carbon of mesoporous activated car...

Embodiment 3

[0046] (1) Preparation of upper layer fabric: take PET chips as the main raw material, send dry nano-silver ion antibacterial masterbatch and PET chips into a screw extruder for blending and melting to make a spinning melt, which is filtered through a melt filter Then, it is sent to the spinning box through the melt pipeline, and measured by the metering pump, the blended melt is spun, cooled, drawn, and rolled by the spinning assembly in the spinning box to obtain PET antibacterial filament, nano-silver The content of the ionic antibacterial masterbatch is 8wt%, and the filaments are woven into knitted fabrics through a knitting machine; The first coating glue is formed into regularly spaced circles and is distributed on the lower surface of the knitted fabric, and the coating area of the first coating glue accounts for 70% of the lower surface area of the knitted fabric, and the glue is to be coated. After completion, sprinkle a layer of uniformly mixed activated carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com