Wear-resistant self-cleaning super-amphiphobic coating and preparation method thereof

A super-amphiphobic, self-cleaning technology, used in coatings, metal material coating processes, ion implantation plating, etc. High temperature resistance and UV resistance, to solve the problem of insufficient light transmittance and mechanical strength, excellent abrasion resistance and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

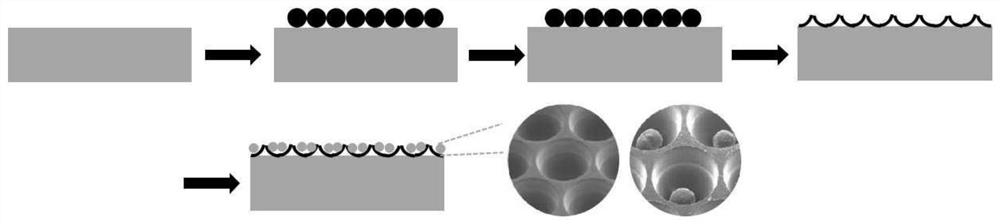

Method used

Image

Examples

Embodiment 1

[0053]Take 9.23ml styrene as monomer, 0.84g polyvinylpyrrolidone (PVP) as emulsifier, 40ml ethanol and 14ml water as solvent, 0.2g azobisisobutyronitrile (AIBN) as initiator, and prepare polystyrene by emulsion polymerization Microsphere emulsion; heated to 80 ° C for 8 hours, diluted with ethanol and water after the reaction, the particle size of polystyrene microspheres is 1 μm;

Embodiment 2

[0055] Take 12ml of styrene as a monomer, 0.84g of polyvinylpyrrolidone (PVP) as an emulsifier, 40ml of ethanol and 14ml of water as a solvent, and 0.2g of azobisisobutyronitrile (AIBN) as an initiator, and prepare polystyrene microparticles by emulsion polymerization. Ball emulsion; heated to 100 ° C for 12 hours, diluted with ethanol and water after the reaction, the particle size of polystyrene microspheres is 2 μm;

Embodiment 3

[0057] The glass slide was immersed in the polystyrene emulsion obtained in Example 1 for 15 minutes, and then the substrate was vertically pulled out of the coating solution at a speed of 250 μm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com