Fresh flower non-destructive low-temperature extraction process

A non-destructive, fresh flower technology, applied in the direction of climate sustainability, fat production, energy-saving heating/cooling, etc., can solve the problems of degraded aroma, degraded quality of flower liquid, destruction, etc., to improve quality, ensure quality and aroma, Avoid churn effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

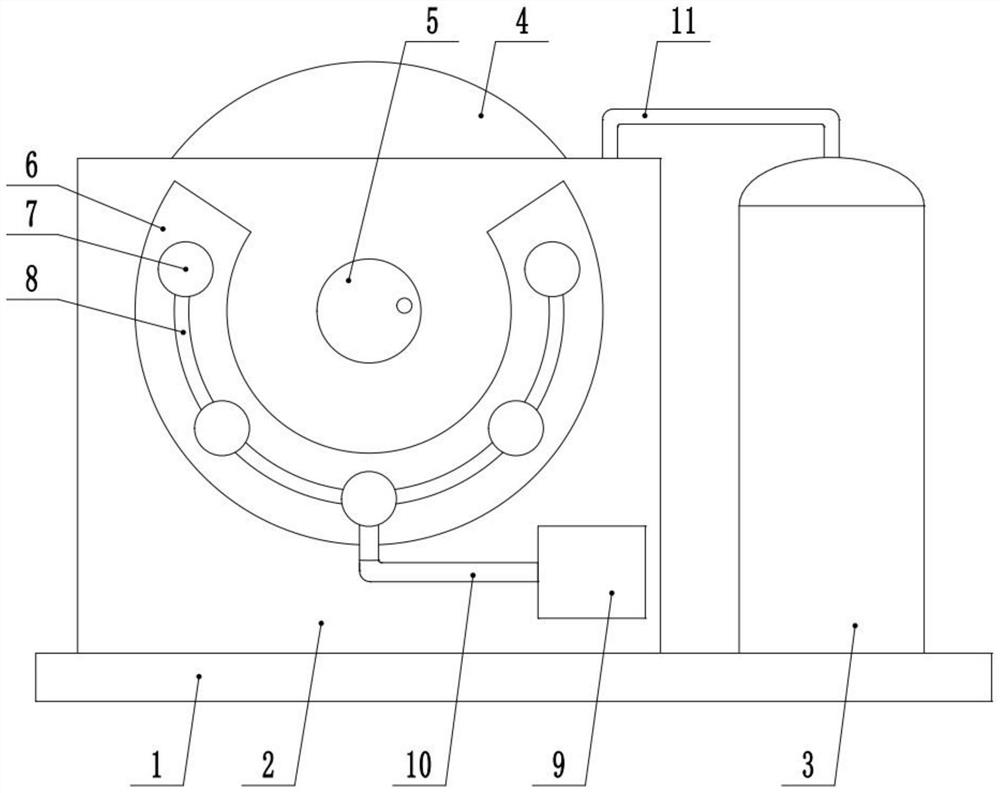

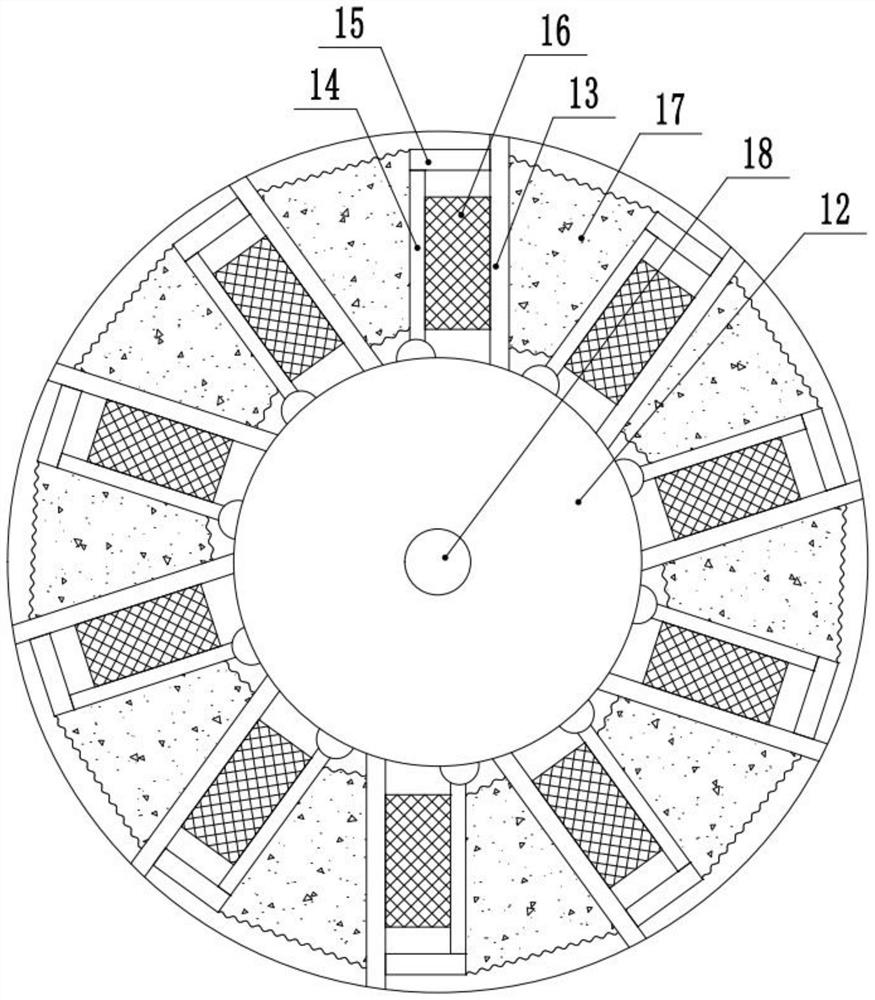

[0026] A non-destructive low-temperature extraction process for fresh flowers, comprising the following steps:

[0027] Step 1, flower collection: collect flowers with mature and complete leaves;

[0028] Step 2. Pretreatment: The collected fresh flowers are sprayed, rinsed, dedusted and decontaminated, and then disinfected. After disinfection, the fresh flowers are lightly rubbed to break the skin;

[0029] Step 3. Preparation of the extraction environment: prepare the extraction device, first clean the extraction device, then sterilize it with ultraviolet radiation, place the fresh flowers in the extraction device, and then seal the extraction device;

[0030] Step 4. Low-temperature cold air treatment: After the sealed space is formed, the extraction device is connected to the heat pump system, and the petals of the flowers are extracted by low-temperature cold air. The cold air generated by the heat pump volatilizes the original liquid contained in the flowers into wet gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com