A kind of preparation method of azobenzene oxide

A technology for azobenzene oxide and compounds, applied in the field of preparation of azobenzene oxide, can solve the problems of large environmental pollution, high cost, high risk and the like, and achieve the effects of small environmental pollution, low cost and novel method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

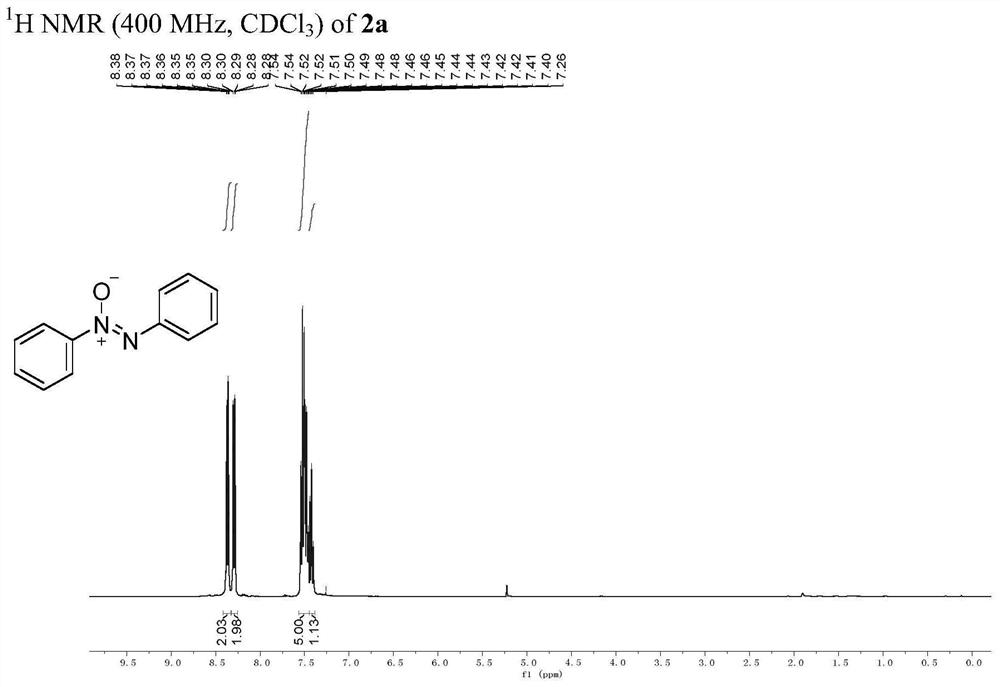

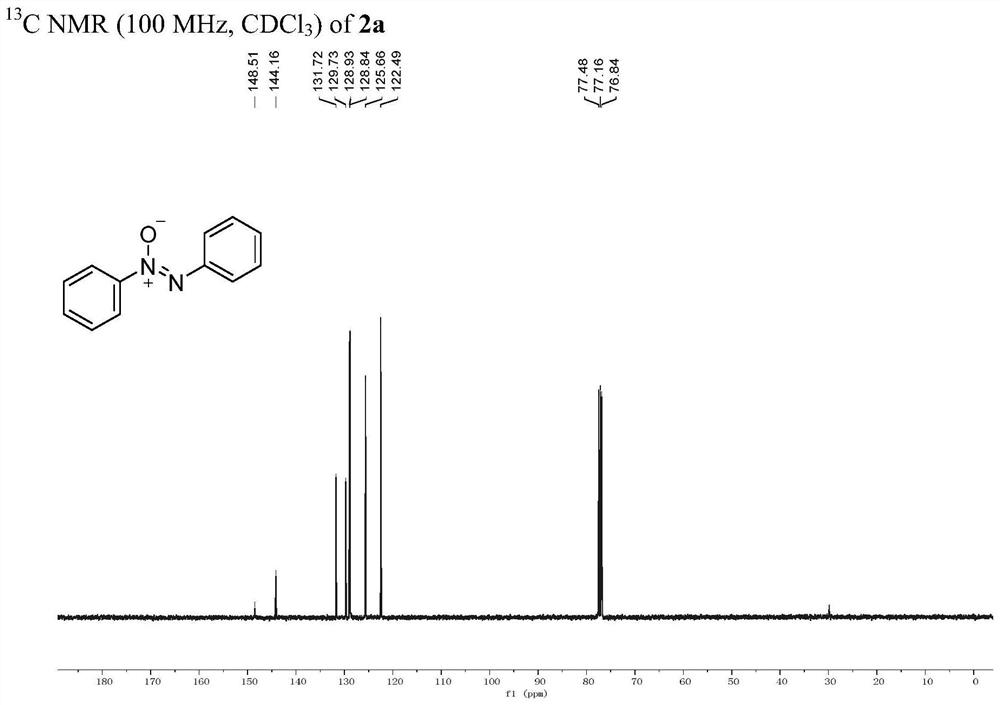

Embodiment 1

[0039]

[0040] Add compound nitrobenzene (25mg, 0.2mmol), LiClO 4 (10.6mg, 0.1mmol), a rubber stopper at the mouth of a bottle passes through a platinum wire and a silver wire as wires, and the lower ends of the wires are respectively connected with two pieces of graphite felt (2cm×1cm×0.5cm). The middle of the graphite felt is separated by a Teflon film, and then the two graphite felts are fastened with a Teflon thread. The graphite felt connected with platinum wire is used as the anode of the electrolysis reaction, and the graphite felt connected with the silver wire is used as the cathode of the electrolysis reaction. The reaction flask was filled with ammonia gas 3 times, and then 5 mL of dry CH was added. 3 CN. The reaction was performed at a constant voltage of 6V at room temperature, and the reaction was monitored by TLC and GC-MS. After about 4 hours of reaction, transfer the original reaction solution, add ethyl acetate to wash, mix the original solution with t...

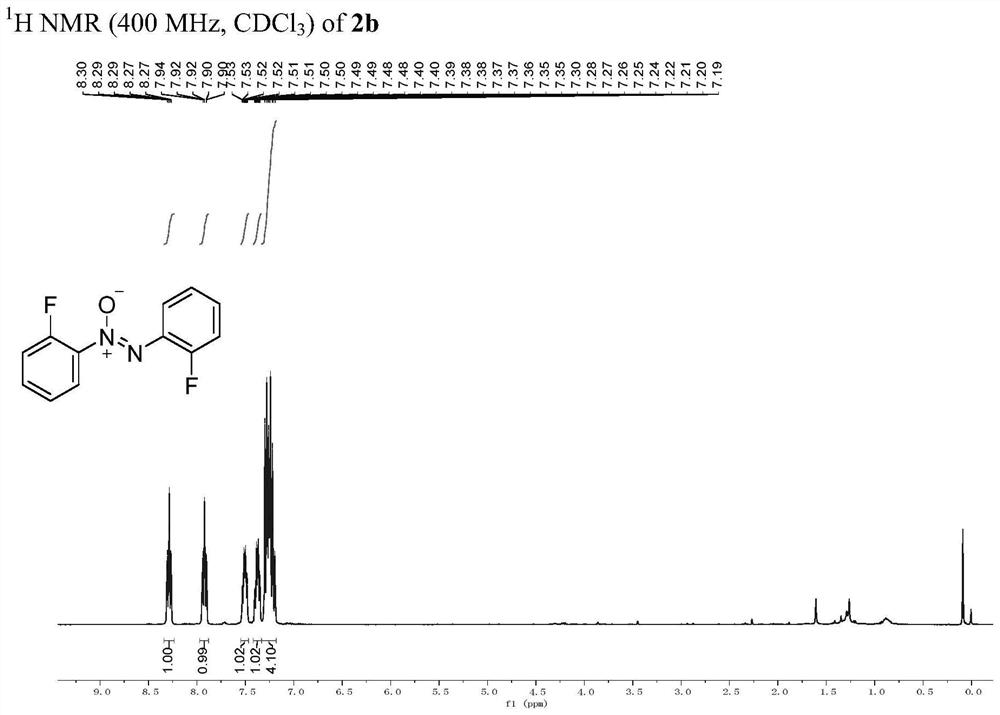

Embodiment 2

[0043]

[0044] Add compound o-fluoronitrobenzene (28mg, 0.2mmol), LiClO 4 (10.6mg, 0.1mmol), a rubber stopper at the mouth of a bottle passes through a platinum wire and a silver wire as wires, and the lower ends of the wires are respectively connected with two pieces of graphite felt (2cm×1cm×0.5cm). The middle of the graphite felt is separated by a Teflon film, and then the two graphite felts are fastened with a Teflon thread. The graphite felt connected with platinum wire is used as the anode of the electrolysis reaction, and the graphite felt connected with the silver wire is used as the cathode of the electrolysis reaction. The reaction flask was filled with ammonia gas 3 times, and then 5 mL of dry CH was added. 3 CN. The reaction was performed at a constant voltage of 6V at room temperature, and the reaction was monitored by TLC and GC-MS. After about 4 hours of reaction, transfer the original reaction solution, add ethyl acetate to wash, mix the original solutio...

Embodiment 3

[0047]

[0048] Add compound o-trifluoromethylnitrobenzene (38mg, 0.2mmol), LiClO 4 (10.6mg, 0.1mmol), a rubber stopper at the mouth of a bottle passes through a platinum wire and a silver wire as wires, and the lower ends of the wires are respectively connected with two pieces of graphite felt (2cm×1cm×0.5cm). The middle of the graphite felt is separated by a Teflon film, and then the two graphite felts are fastened with a Teflon thread. The graphite felt connected with platinum wire is used as the anode of the electrolysis reaction, and the graphite felt connected with the silver wire is used as the cathode of the electrolysis reaction. The reaction flask was filled with ammonia gas 3 times, and then 5 mL of dry CH was added. 3 CN. The reaction was performed at a constant voltage of 6V at room temperature, and the reaction was monitored by TLC and GC-MS. After about 4 hours of reaction, transfer the original reaction solution, add ethyl acetate to wash, mix the origina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com