Method for controlling initial temperature of gas in first firing cycle cylinder of engine

An engine cylinder and engine technology, which is applied in the direction of engine ignition, engine components, engine control, etc., can solve the problems of difficult precise control of cylinder gas temperature, reduced engine test efficiency, and rise in air temperature, so as to shorten the time of backtracking and reduce fuel consumption. Consumption, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

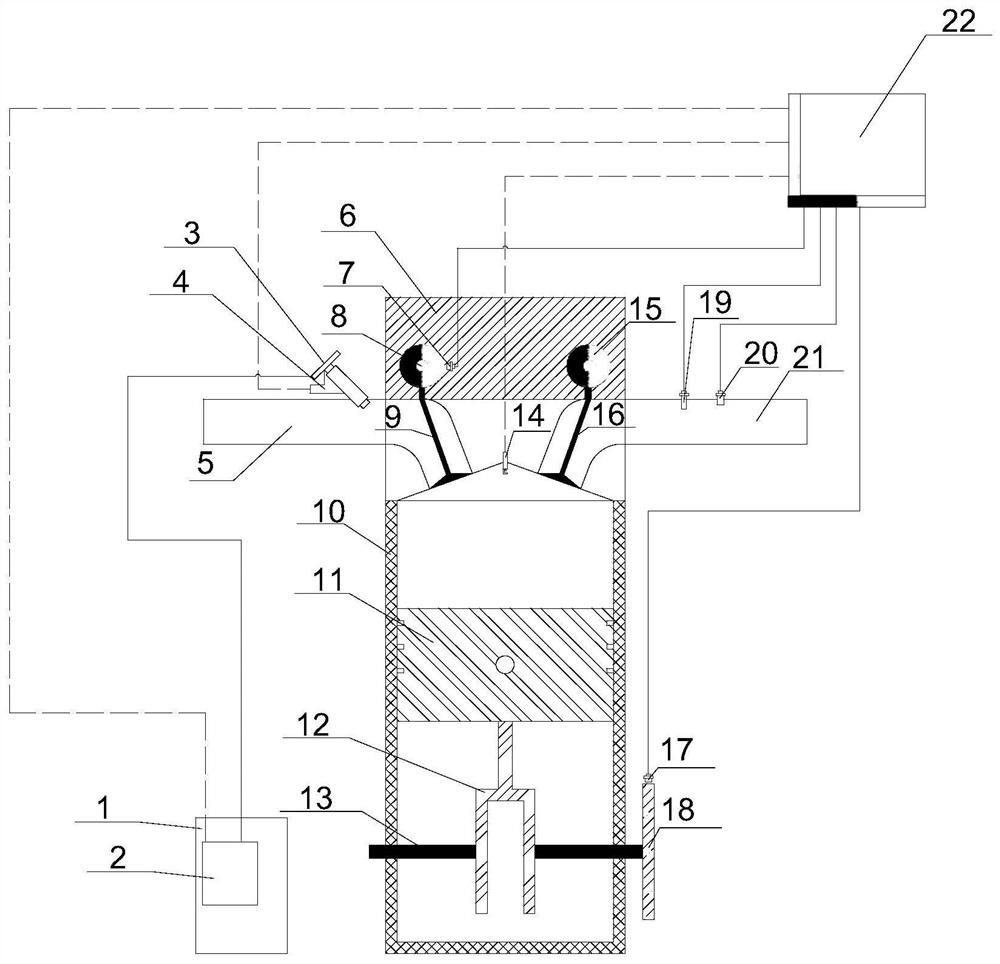

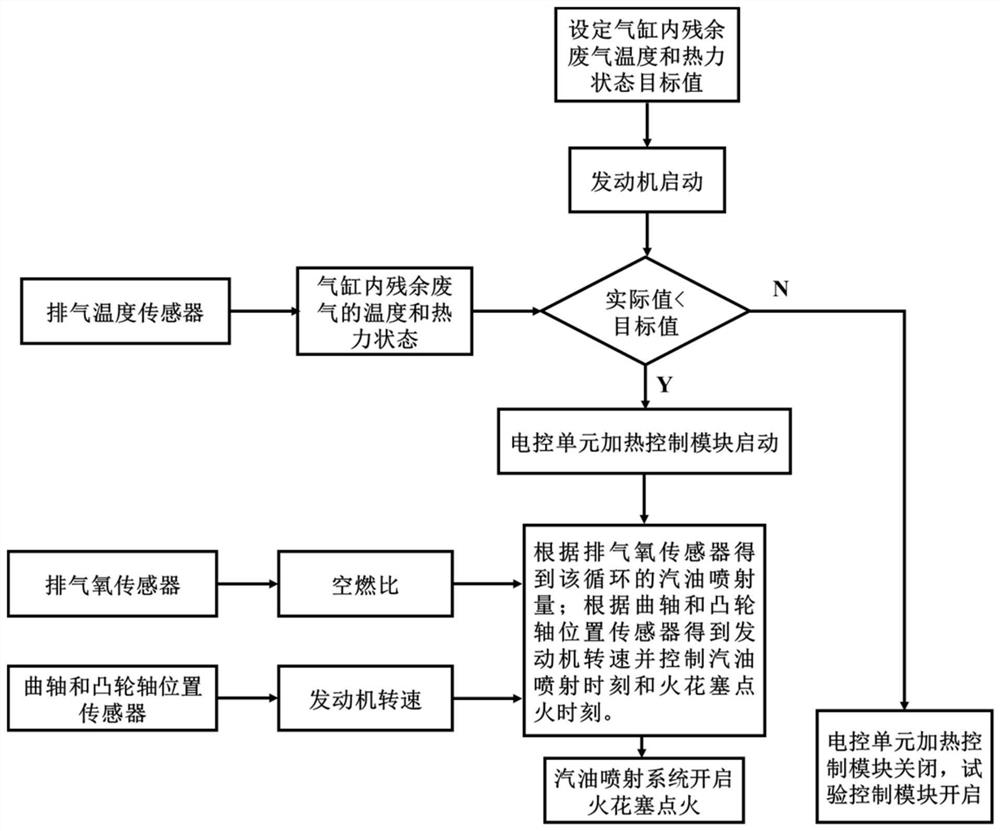

[0023] combine Figure 1-2 , to specifically describe the embodiments of the present invention.

[0024] A method for quickly controlling the initial temperature of the gas in the cylinder of the first ignition cycle of the engine. The gasoline injection control system includes: gasoline tank 1, gasoline pump 2, gasoline fuel rail 3, crankshaft position sensor 17, camshaft position sensor 7, exhaust The temperature sensor 19, the exhaust oxygen sensor 20 and the electronic control unit 22; the gasoline fuel rail 3 and the gasoline injector 4 are installed on the engine intake pipe 5, and the spark plug 14 is installed in the engine cylinder. All sensors, gasoline injector 4, and gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com