Shock-resistant high-sensitivity induction detection sensor measuring device

A high-sensitivity, inductive detection technology, applied in the direction of measuring devices, testing/calibrating devices, measuring capacity, etc., can solve problems such as unstoppable sensors, affecting measurement accuracy, and probe rod breakage, achieving high measurement accuracy and low signal-to-noise Good ratio, the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

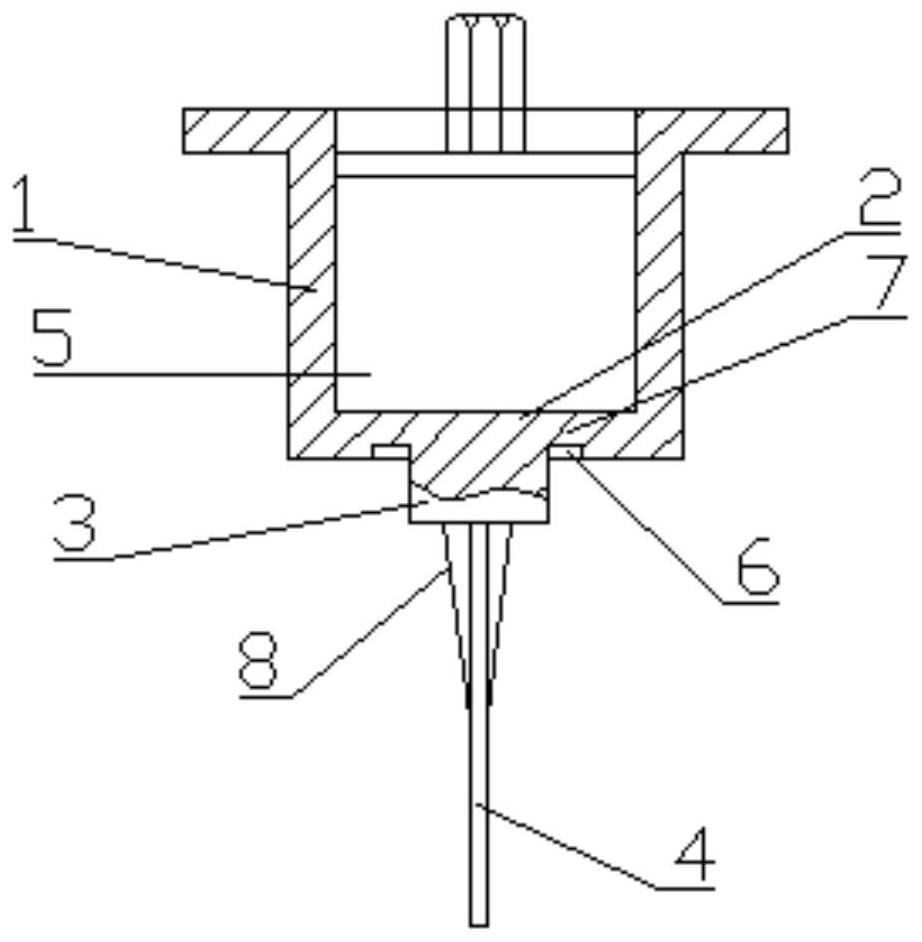

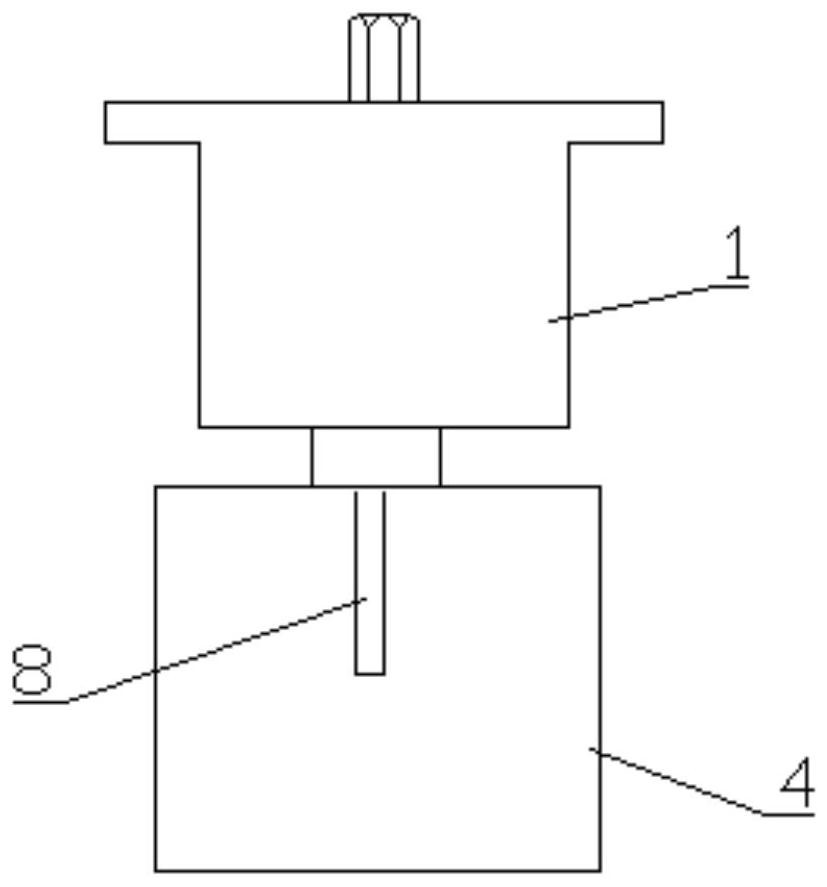

[0027] Such as figure 1 with figure 2In the shown embodiment, an anti-seismic high-sensitivity induction detection sensor measuring device includes a measuring cavity 1, and the measuring cavity 1 is a welded threaded measuring cavity, or a flanged threaded measuring cavity; the measuring cavity The lower end of the body 1 is provided with a shock-sensing sheet 2, the lower end of the shock-sensing sheet 2 is provided with a cylinder 3, the lower end of the cylinder 3 is provided with a shock-absorbing signal vibration mechanism 4, and the inside of the measuring cavity 1 is provided with a detection sensor 5, The lower end surface of the vibration-sensing sheet 2 is provided with an annular groove 6 and an annular sheet 7 , and the detection sensor 5 is arranged on the upper end surface of the vibration-sensing sheet 2 by packaging or pressing with a fastener.

[0028] In this embodiment, the earthquake-resistant high-sensitivity induction detection sensor measuring device ...

Embodiment 2

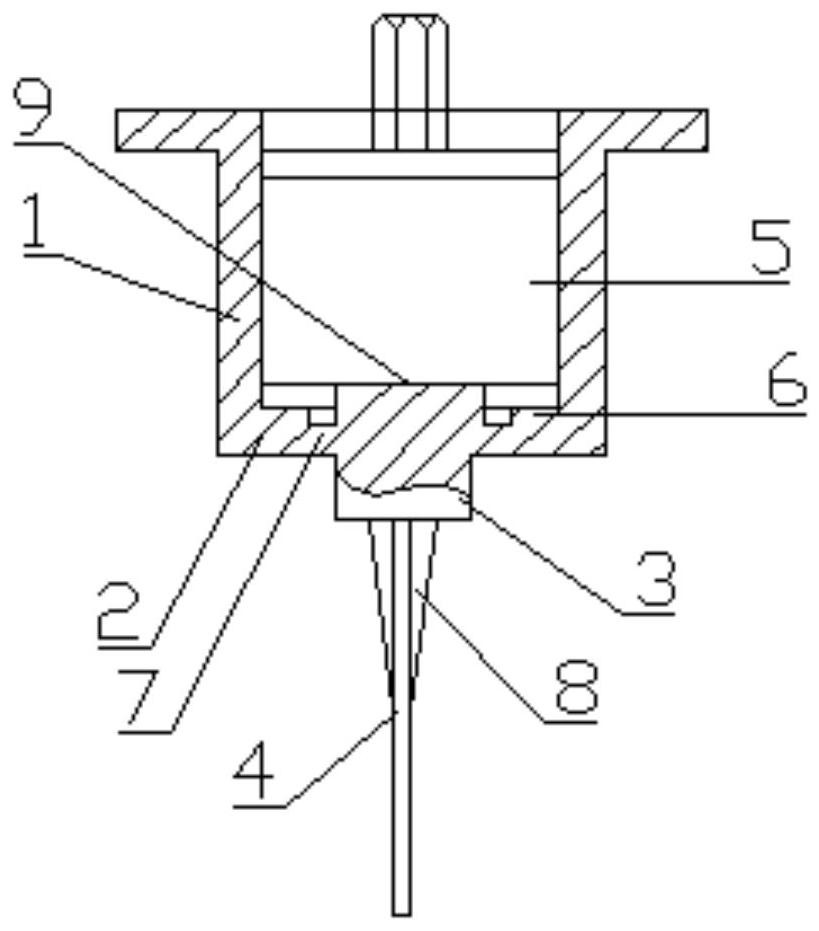

[0034] Such as image 3 In the shown embodiment, an anti-seismic high-sensitivity induction detection sensor measuring device includes a measuring cavity 1, and the measuring cavity 1 is a welded threaded measuring cavity, or a flanged threaded measuring cavity; the measuring cavity The lower end of the body 1 is provided with a shock-sensing sheet 2, the lower end of the shock-sensing sheet 2 is provided with a cylinder 3, the lower end of the cylinder 3 is provided with a shock-absorbing signal vibration mechanism 4, and the inside of the measuring cavity 1 is provided with a detection sensor 5, The upper end surface of the shock-sensing sheet 2 is provided with an annular groove 6 and an annular sheet 7, the upper end of the shock-sensing sheet 2 is provided with an upper cylinder 9, and the detection sensor 5 is arranged on the upper cylinder by packaging or tightening with fasteners. 9 on the end face.

[0035] In this embodiment, the earthquake-resistant high-sensitivit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com