Pre-expanded polyamide beads, molded polyamide foam, and production method therefor

A foamed molded body and a manufacturing method technology, applied in the field of polyamide pre-expanded particles, can solve the problems of inability to use heat resistance, poor heat resistance, etc., and achieve the effects of improving fusion property and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

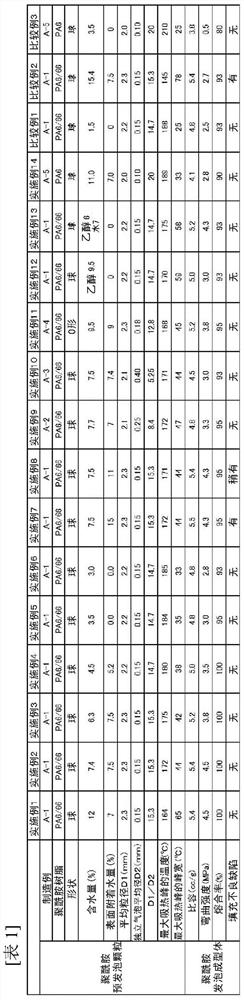

[0157] Embodiments of the present invention are described below by way of examples. However, the scope of the present invention is not limited by the Examples at all.

[0158] Evaluation methods used in Examples and Comparative Examples will be described below.

[0159] (1-1) Moisture content of polyamide pre-expanded particles

[0160] After weighing the amide pre-expanded particles (W0), the particles were spread on a dry fiber sheet (Kim Towel Nippon Paper), and other fiber sheets were used to remove surface-adhered water, followed by weighing (W1). After the polyamide pre-expanded particles were vacuum-dried at 80°C for 6 hours, weighed again (W2), calculated respectively water content (%)=(W1-W2) / W2×100 and surface attached water (%) =(W0-W1) / W2×100.

[0161] (1-2) Moisture content of polyamide pre-expanded particles having a hollow portion or a concave shape portion

[0162] After weighing the polyamide pre-expanded particles (W0), fill the polyamide pre-expanded par...

Embodiment 1

[0197]The polyamide pre-expanded particles of Production Example (A-1) were put into a water-permeable non-woven bag, and immersed in a constant temperature water tank heated to 50° C. for 30 minutes to obtain water-containing polyamide pre-expanded particles. The polyamide pre-expanded particles had a water content of 12%, a surface-attached water content of 7.0%, an average particle diameter (D1) of 2.3 mm, and an average diameter (D2) of independent cells of 0.15 mm.

[0198] The obtained polyamide pre-expanded particles were sealed in an autoclave, and compressed air was introduced for 1 hour until the pressure in the autoclave reached 0.4 MPa, and then the pressure was maintained at 0.4 MPa for 24 hours, thereby pre-expanding the polyamide. The pellets are subjected to pressure treatment.

[0199] Fill the pressure-treated polyamide pre-expanded particles into the cavity of the in-mold molding mold (the dimensions of the cavity are vertical: 300mm, horizontal: 300mm, and ...

Embodiment 2

[0202] The polyamide pre-expanded particles of Production Example (A-1) were packed into a water-permeable non-woven bag, immersed in a constant temperature water tank heated to 50°C for 5 minutes, and then carried out at 1000rpm / min by a dehydrator for 3 minutes. Dehydration treatment to obtain water-containing polyamide pre-expanded particles. The polyamide pre-expanded particles had a moisture content of 7.4%, a surface adhesion moisture content of 7.5%, an average particle diameter (D1) of 2.3 mm, and an average diameter (D2) of independent cells of 0.15 mm.

[0203] The obtained polyamide pre-expanded particles were sealed in an autoclave, and compressed air was introduced for 1 hour until the pressure in the autoclave reached 0.4 MPa, and then the pressure was maintained at 0.4 MPa for 24 hours, thereby pre-expanding the polyamide. The pellets are subjected to pressure treatment.

[0204] Fill the pressure-treated polyamide pre-expanded particles into the cavity of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average diameter | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com