Aquaculture device with feeding function

An aquaculture and functional technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of small feeding coverage, aggregation of aquatic products, and injury of aquatic products, and achieve the effect of uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

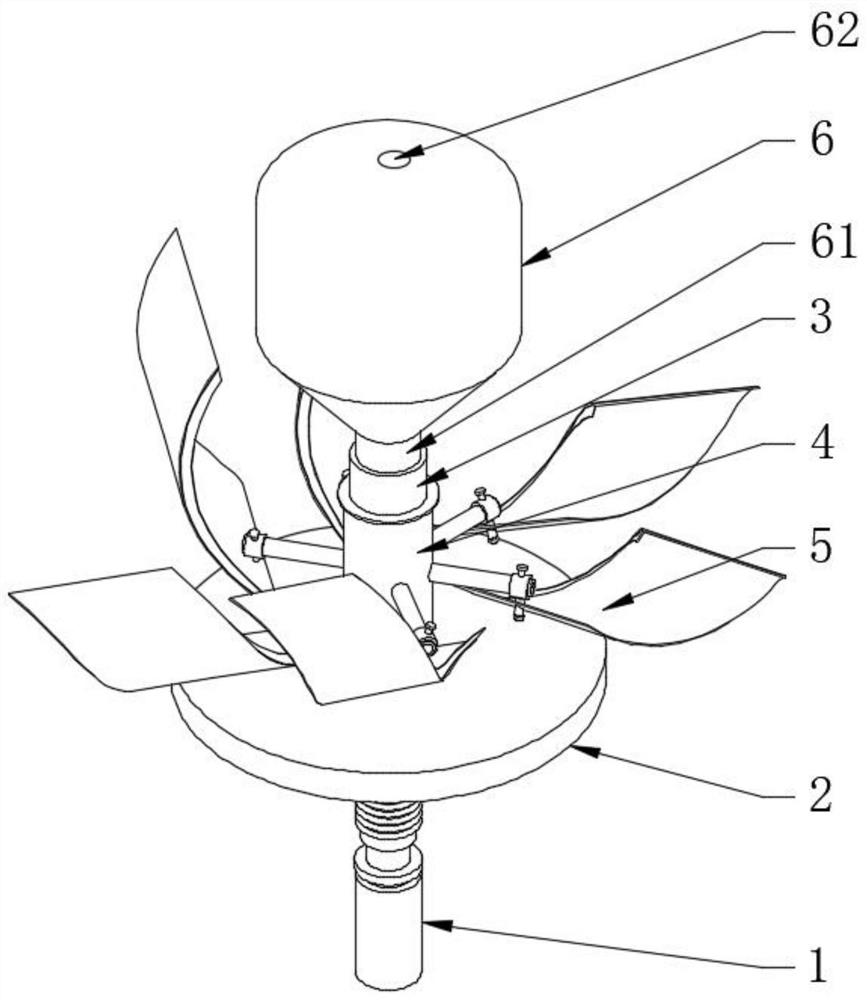

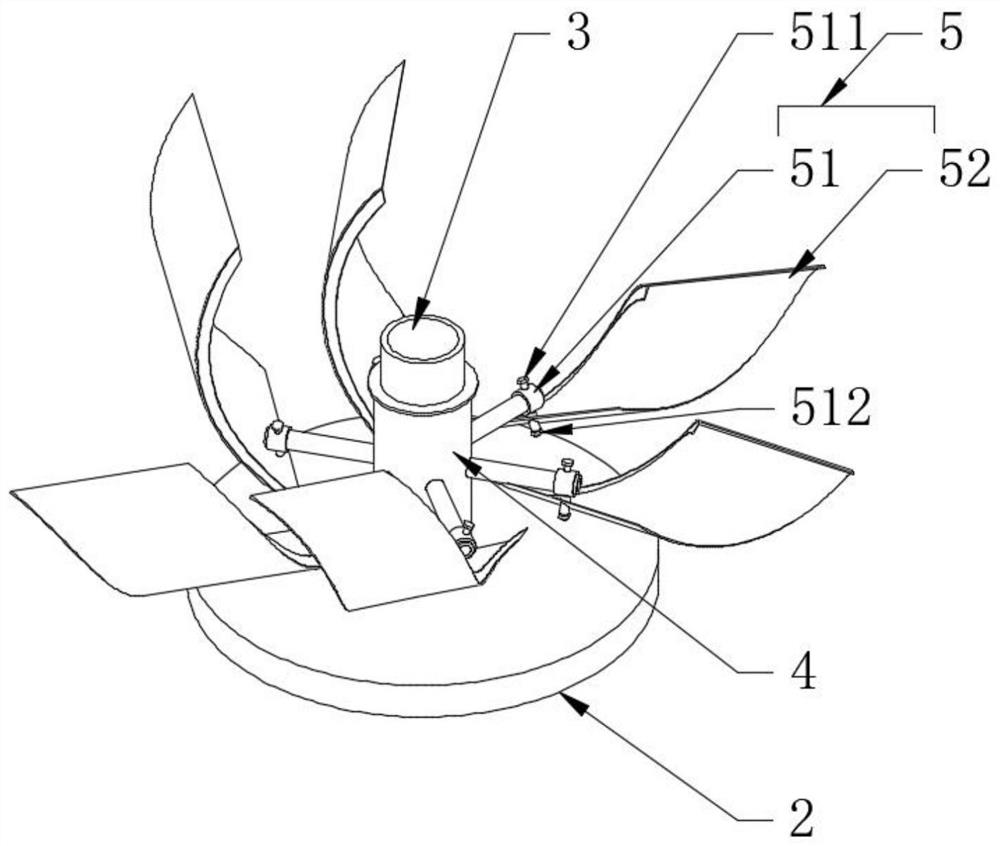

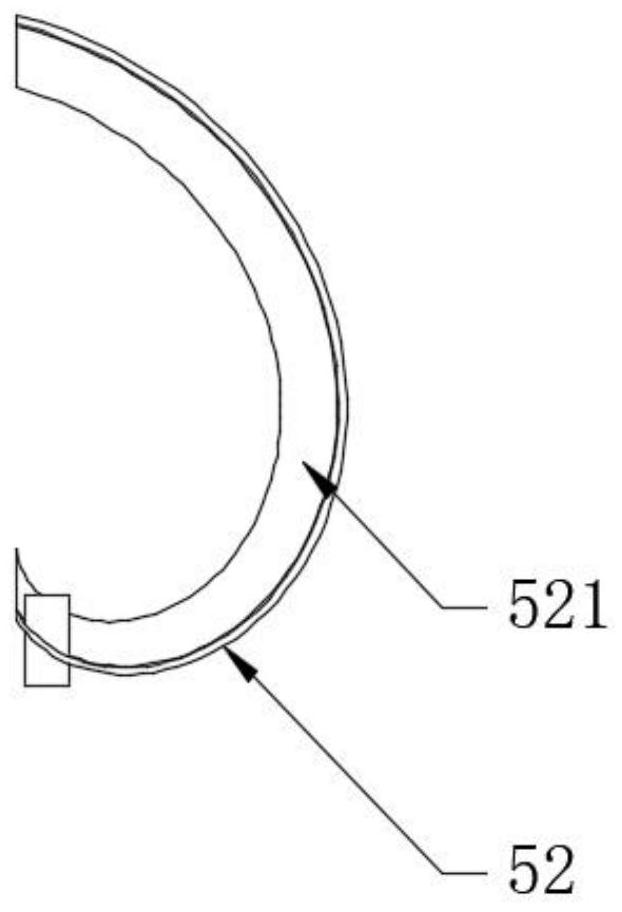

[0032] see Figure 1-6, an aquaculture device with a feeding function, including a water pump 1, a floating plate 2, a convective mixing output pipe 3, a diversion base pipe 4, a throwing combination 5 and a bucket 6, and the water pump 1 is a submersible pump for placing under water For pumping water, the floating plate 2 acts as a seat plate and floats on the water surface, the convective mixing output pipe 3 is used for mixing feed and water entering from the outside, and the function of the diversion base pipe 4 is to discharge the mixture of feed and water, and the throwing combination 5. The feed-water mixture is thrown out to the periphery in the form of "flaky" centered on the convective mixing output pipe 3, and the bucket 6 is used to hold the feed; the split base pipe 4 is set outside the convective mixing output pipe 3 and For rotation fit, the bottom of the diversion base pipe 4 runs through the floating plate 2 and is fixedly connected, the water outlet of the wa...

Embodiment 2

[0034] see Figure 6 The difference with Embodiment 1 is that the number of connecting plates 32 is three and is evenly distributed in the circumferential direction relative to the upper conduit 31. One side of the connecting plate 32 is in clearance fit with the inner surface wall of the branching base pipe 4, and the dividing base pipe 4 When rotating, when the three connecting plates 32 pass through the nozzles of three uniformly distributed guide tubes 41 at the same time, the liquid flow rate through the guide tubes 41 will change, so that the throwing arc can be changed on the basis of Embodiment 1. The throwing distance of the plate 52 has the function of periodically changing the remote and process feeding amount, which facilitates the dispersion of aquatic products and reduces the incidence of bruises.

Embodiment 3

[0036] see Figure 7 The difference from Embodiment 1 is that the top of the branch base pipe 4 is fixedly provided with an elastic resistance increasing sleeve 42, and the outer periphery of the discharge pipe 61 is fixedly provided with a friction disc 611, and the friction disc 611 is used in conjunction with the top of the elastic resistance increasing sleeve 42. The elastic resistance-increasing sleeve 42 is composed of a supporting spring 421 and a wear-resistant washer 422 fixedly arranged on the top of the supporting spring 421. Since the reverse high-speed rotation of the flow-distributing base pipe 4 will reduce the lift of the flow arc plate 52, the elastic resistance-increasing sleeve 42 will be increased. , after the material barrel 6 is installed, the support spring 421 is compressed by its own weight, and then a rotational resistance will be applied to the diversion base pipe 4, which can reduce the rotation speed of the diversion base pipe 4, and increase the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com