Automatic moon cake production line

A production line and moon cake technology, applied in the direction of chemical instruments and methods, mixing/kneading with horizontal installation tools, cleaning methods using tools, etc., can solve the problem of small contact area between straight paddle blades and flour, difficult control of mixing time, and inability to produce raw materials Fully mixed and other issues to achieve the effect of improving baking efficiency, better taste, and reducing the number of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

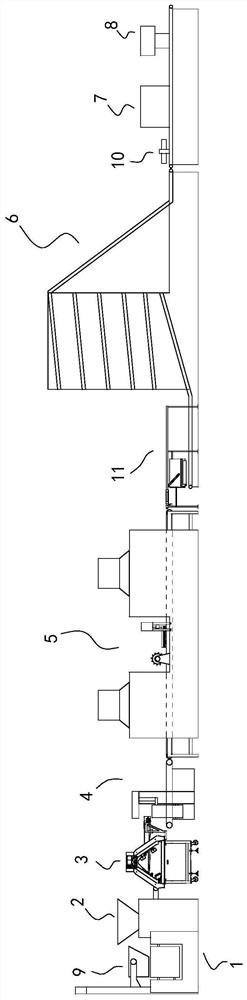

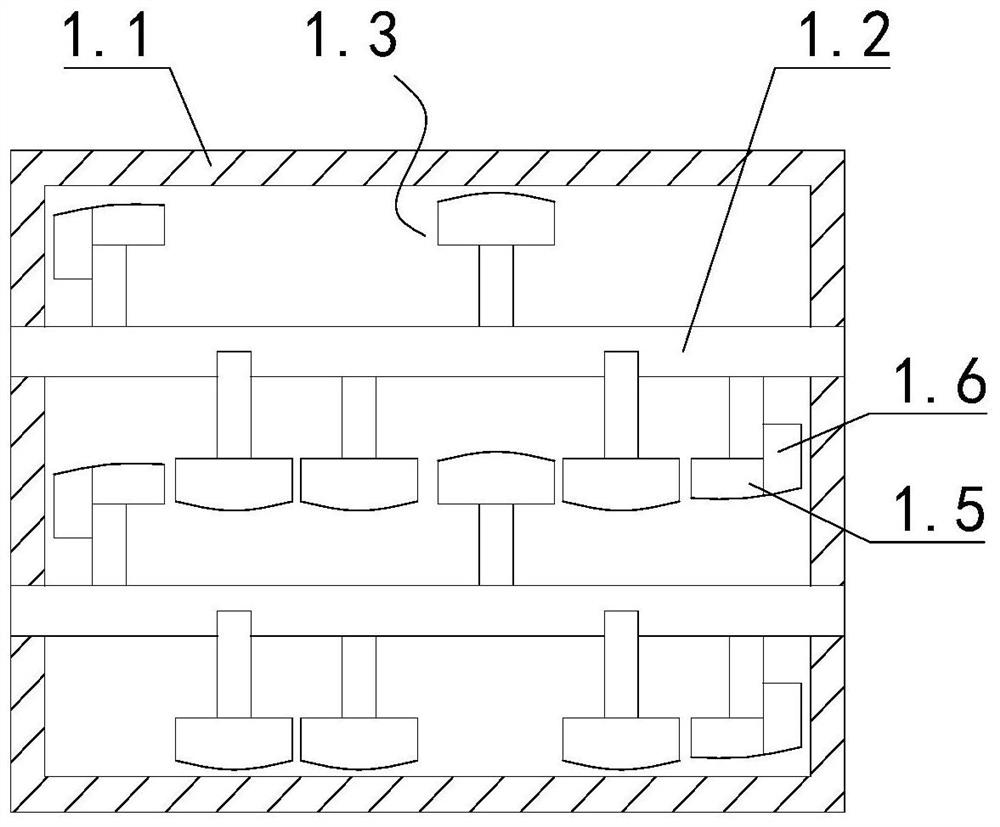

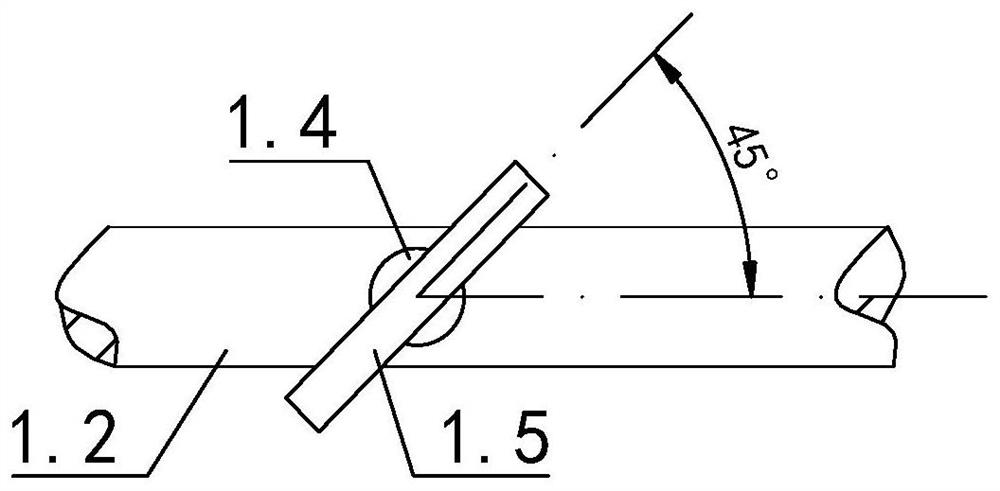

[0054] Such as Figure 1 to Figure 18 As shown, an automated moon cake production line includes a dough mixer 1, a blocker 2, a rounding machine 3, a disc machine 4, a tunnel furnace 5, a turning machine 11, a cooling tower 6, a packaging machine 7 and a printer 8;

[0055] The feed inlet of the blocker 2 is placed below the kneading barrel 1.1 of the dough mixer 1, the end of the discharge belt of the blocker 2 is located directly above the feed inlet 3.6 of the rounder 3, and the forming of the rounder 3 The discharge belt 3.9 is docked with the feed belt of the code disc machine 4, the discharge belt of the code disc machine 4 is docked with one end of the chain conveyor 5.11 of the tunnel furnace 5, and the other end of the chain conveyor 5.11 is connected with the feed of the turner 11. The discharge port of the turning machine 11 is located above the feed port of the cooling tower 6, the discharge port of the cooling tower 6 is docked with the feeding belt 7.1 of the pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com