Core-pulling method of die-casting machine

A technology of die-casting machine and injection mechanism, which is applied in the core-pulling field of die-casting machines, can solve the problems of long core-pulling time, prolonging the production cycle of connecting parts, and decreasing the quality of connecting parts, so as to shorten the production time and shorten the time of core-pulling , the effect of shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The existing core-pulling sequence is: the spraying mechanism sprays the release agent → the spraying mechanism blows air, blows the water on the surface of the cavity and resets it → the equipment mold closing signal is sent → the neutron core puller starts to operate, drives the slide The block core enters the mold cavity and is in place → the mold is closed → the injection mechanism acts to inject raw materials into the cavity → the mold is opened → the neutron core puller acts to make the slider core retract and reset → the ejector mechanism acts, and the product Take it out and go to the next cycle.

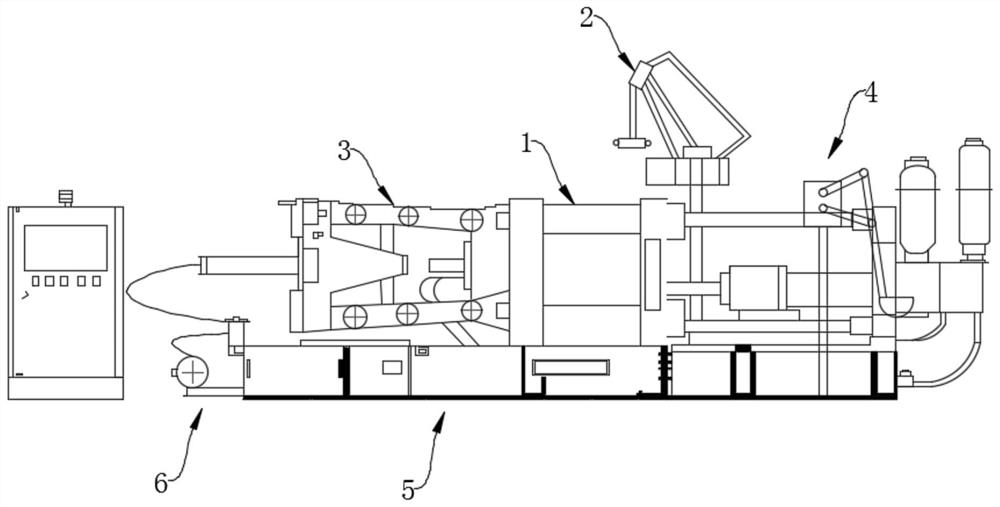

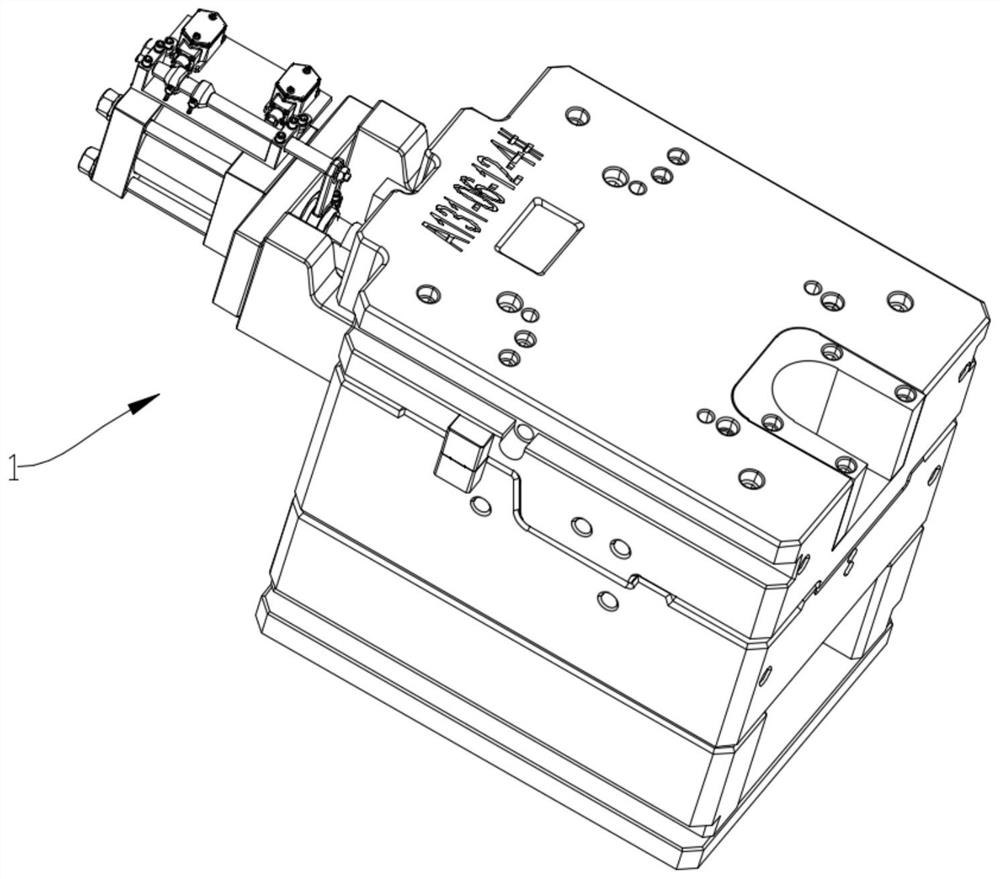

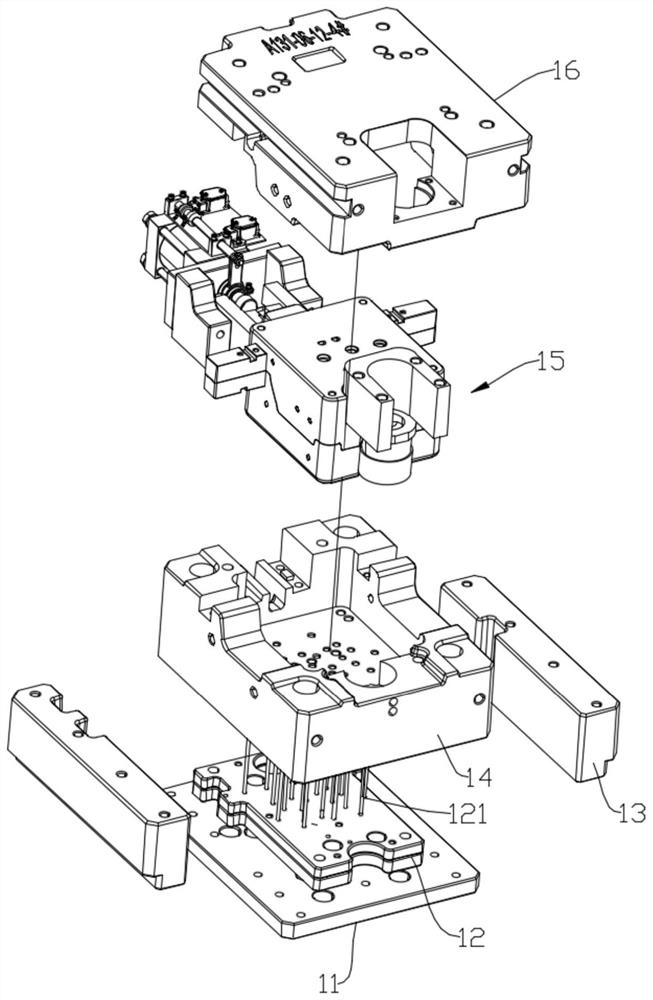

[0038] Such as figure 1 As shown, the equipment involved in the method adopted in the present invention includes: a core-pulling mold 1 , a spraying mechanism 2 , a molding mechanism 3 , an injection mechanism 4 , an oil tank and a machine base 5 , and a hydraulic transmission system 6 . Among them, the core-pulling mold 1, that is, the die-casting machine, is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com