Low-temperature catalyst hot air module

A catalyst module and catalyst technology, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing maintenance cost and difficulty, increasing the risk of nitrogen leakage, and complex structural design, so as to improve the surface temperature of equipment and reduce nitrogen Risk of leakage, effect of increased space inside the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

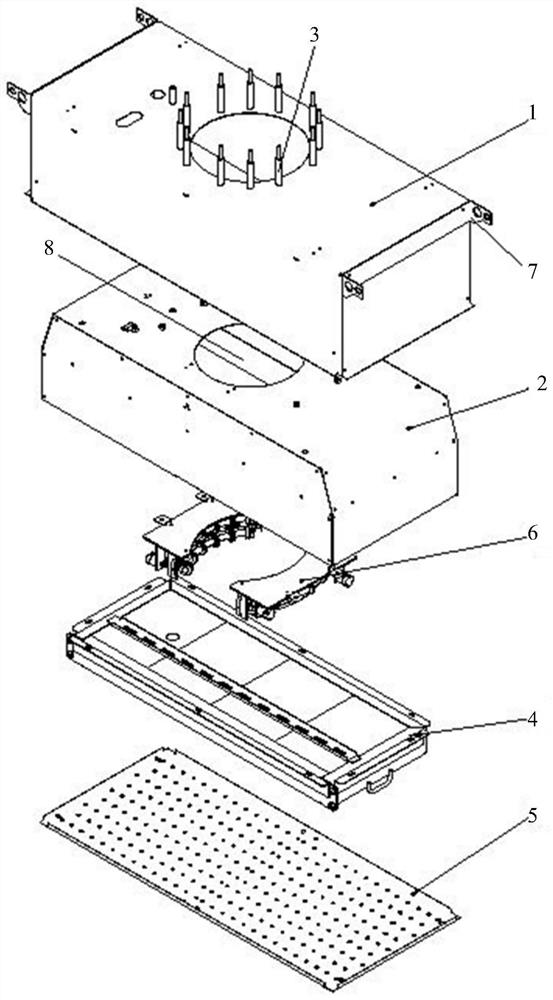

[0029] like figure 1 Shown is the overall explosion structure diagram of the present invention, as can be seen from the figure, the module of the present invention includes the module outer box 1, and the top of the module outer box 1 is integrally formed with a plurality of holes for auxiliary installation of the expansion base and the impeller. Connecting columns 3, and they are arranged at the top position of the outer box body 1 of the module in a circumferential arrangement, the circumference surrounded by the connecting columns 3 is provided with a round hole, and the impeller enters the heating wire through the round hole and the air inlet 8 In the middle of the module 6, the gap formed between the two ends of the module outer box 1 and the module inner box 2 due to the size difference is used as the air suction port of the whole module. In addition, the module outer box 1 is also equipped with a For the connection ear 7 installed and connected with the reflow soldering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com